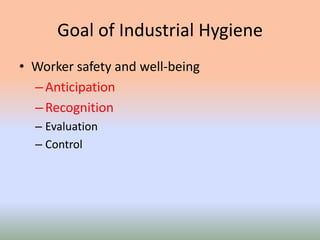

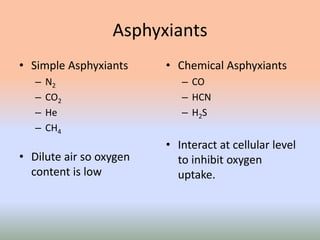

The document discusses various workplace hazards grouped into four categories: chemical, physical, ergonomic, and biological. It provides examples and details of common hazards within each category. The goal of industrial hygiene is to anticipate hazards, recognize their effects, evaluate exposures, and implement controls to protect worker safety and well-being. The document emphasizes that occupiers have a responsibility to be aware of hazards, design safer systems, and encourage proper safety procedures through good management.