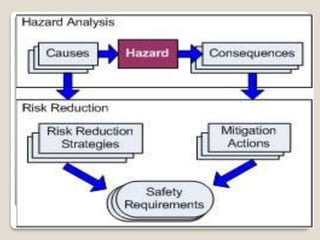

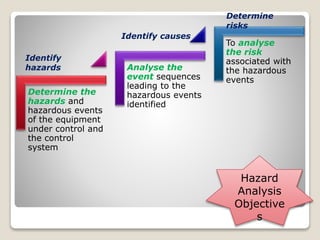

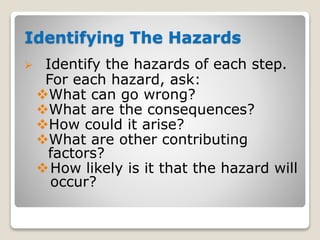

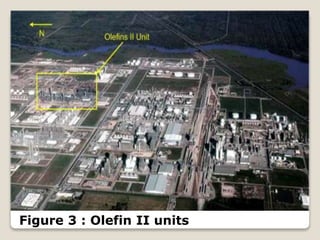

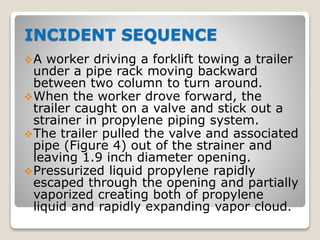

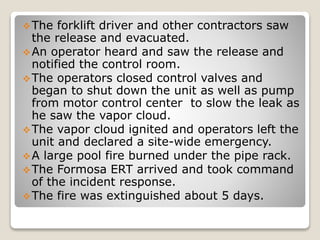

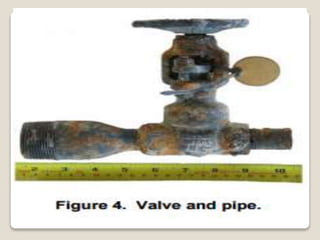

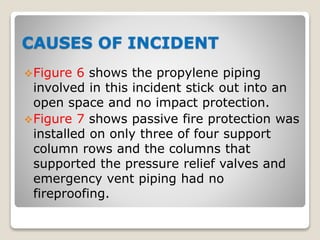

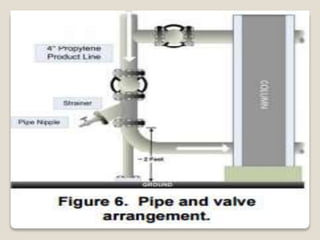

This document provides information on hazard analysis. It defines a hazard and lists common types of hazards including chemical, physical, biological, ergonomic, and noise hazards. It then discusses what hazard analysis is and different methods used, including job hazard analysis, hazard and operability study, fault tree analysis, and process hazard analysis. As a case study, it summarizes a 2005 fire and explosion at a Formosa Plastics plant in Texas, caused by a forklift pulling a valve from a propylene line. Lessons learned include considering vehicle impacts and remote isolation in hazard analyses.