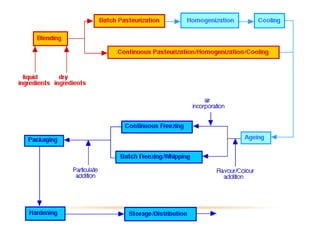

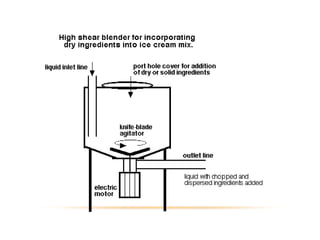

Ice cream is composed of greater than 10% milkfat, 9-12% milk solids, 12-16% sweeteners, and 0.2-0.5% stabilizers and emulsifiers. Other frozen desserts include frozen custard, frozen yogurt, gelato, ice milk, sherbet, and sorbet. Liquid nitrogen can be used to rapidly freeze ice cream, resulting in many small ice crystals and a creamier texture. The basic process of ice cream production involves blending ingredients, pasteurizing, homogenizing, aging the mix overnight, freezing in a barrel freezer, adding mix-ins, and hardening in a blast freezer.