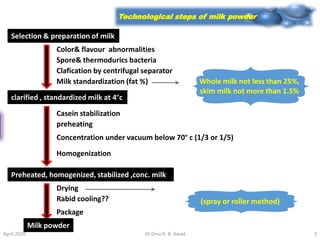

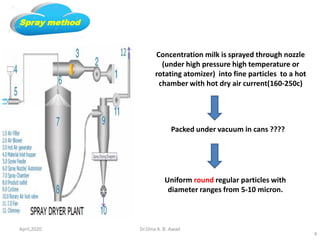

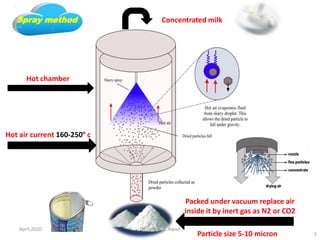

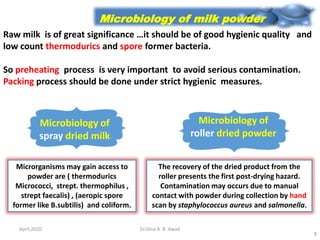

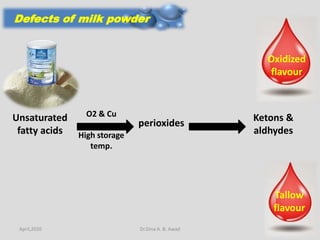

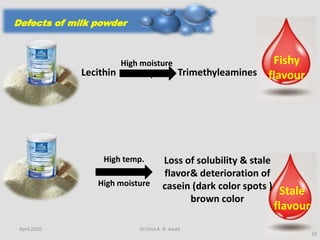

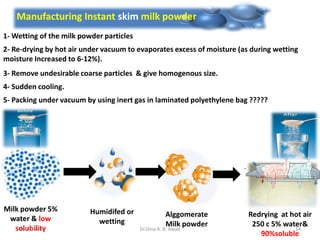

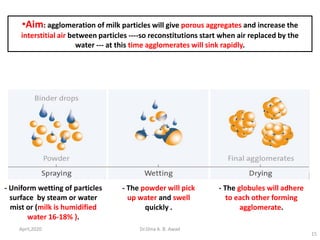

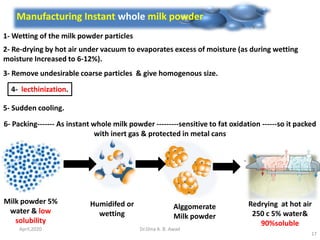

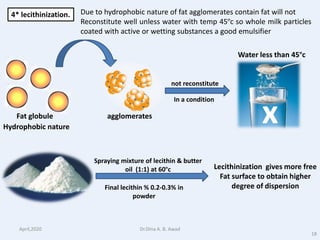

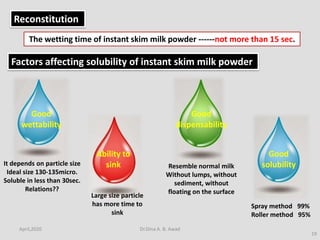

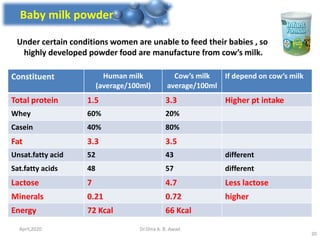

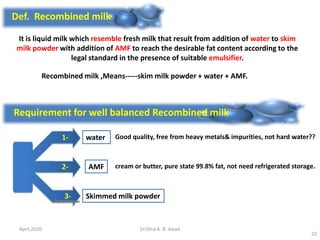

The document discusses the production and properties of various types of milk powder, including whole and skimmed milk powders, and their manufacturing techniques such as spray and roller methods. It addresses issues related to microbiological quality, potential defects in milk powder, and methods to improve solubility and reconstitution, particularly for instant milk powders. Additionally, it covers the nutritional aspects and formulations for baby milk powder from cow's milk to closely resemble human milk.