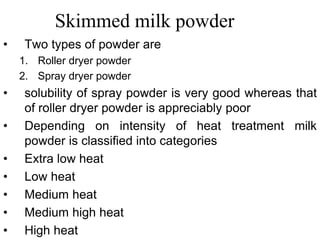

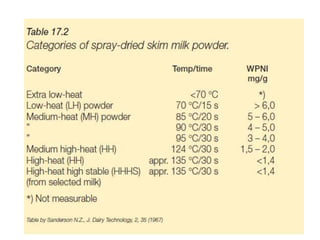

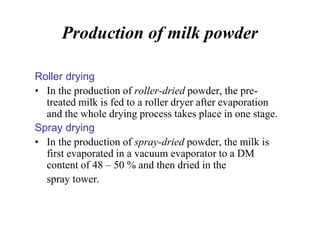

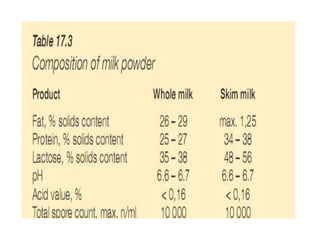

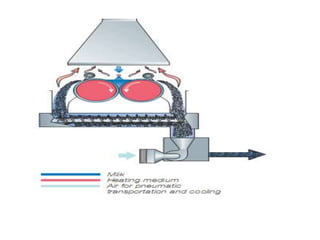

The document summarizes information about milk powder production. Milk is dried either through roller drying or spray drying. Roller drying involves spreading milk on heated rollers, while spray drying atomizes concentrated milk into a drying chamber with hot air. Skim milk powder has a longer shelf life than whole milk powder. Milk powder is used in many food applications due to its light weight and long shelf life. Strict quality standards are followed for milk used in powder production.