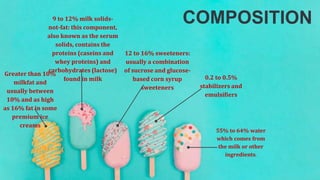

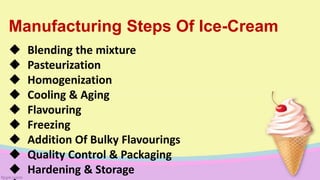

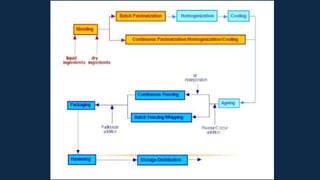

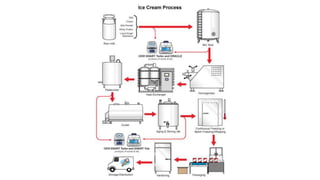

This document summarizes the process for manufacturing ice cream. It involves blending cream and milk products with sugar and flavorings. The mixture is pasteurized, homogenized, cooled, aged, and flavored. It is then frozen while incorporating air, which increases the volume. Bulk flavorings may be added after freezing. The frozen ice cream undergoes quality control testing before being packaged and hardened for storage. The final product is kept at cold temperatures until distribution.