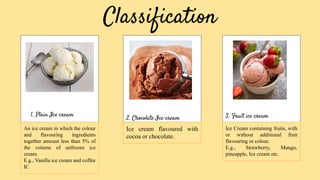

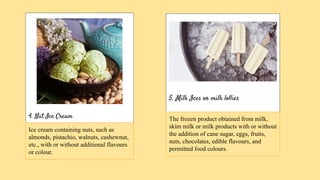

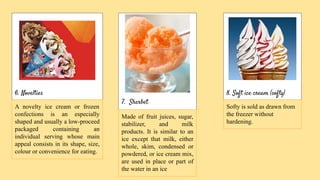

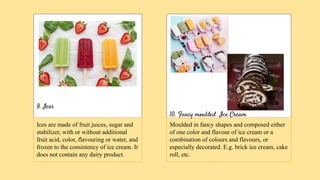

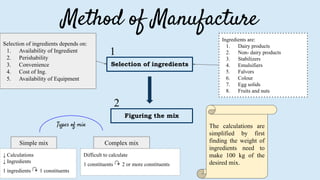

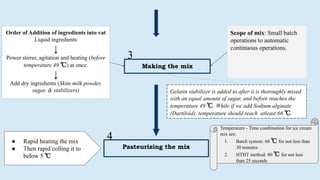

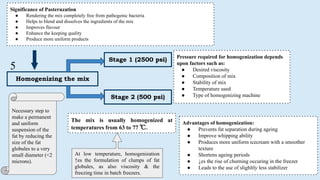

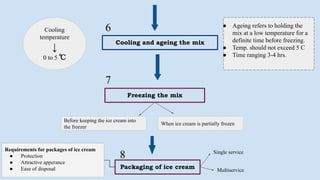

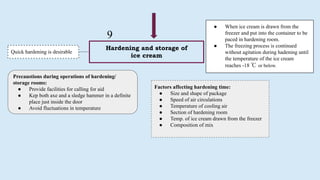

The document provides a comprehensive overview of ice cream, detailing its definition, ingredients, classifications, manufacturing methods, and quality aspects. It describes various types of ice cream, including plain, chocolate, fruit, and novelty, as well as the processes involved in making and storing ice cream. The document also discusses the importance of pasteurization, homogenization, and proper packaging in ensuring the quality and safety of ice cream.