- Spray drying and drum drying are two common methods for dehydrating milk into powder.

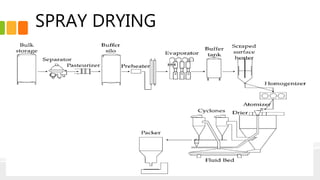

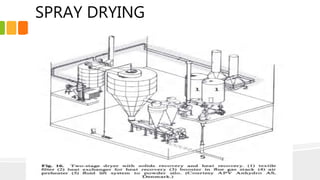

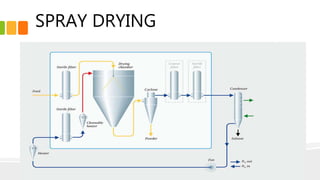

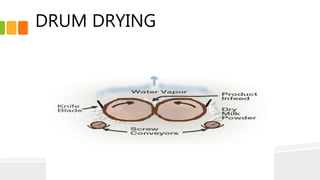

- In spray drying, milk is evaporated, sprayed into hot air as fine droplets, and dried. In drum drying, concentrated milk is applied to heated rotating drums and dried.

- Milk powder has a longer shelf life than liquid milk and can be stored and transported more easily while retaining similar nutritional value when reconstituted. However, drying requires a large amount of energy.