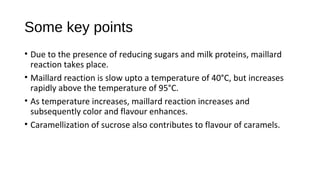

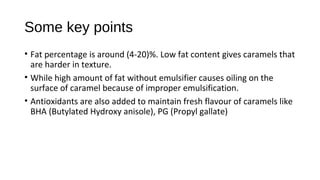

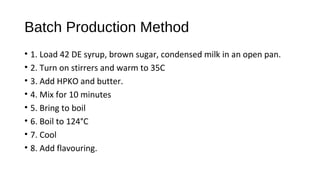

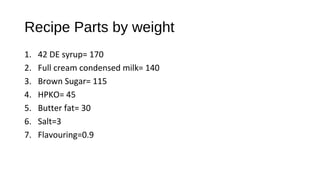

Toffees are defined as an oil-in-water emulsion containing fat globules dispersed in an aqueous sugar and glucose syrup matrix. The key ingredients in toffees include sugars, glucose syrup, condensed milk, and fat. Toffees are produced through a process of dissolving ingredients, emulsifying the fat and milk solids, cooking the mixture to around 124°C, and shaping the toffee through slab, cut and wrap, or depositing methods. The Maillard reaction and caramelization during cooking are responsible for the flavor development in toffees.