Chhana

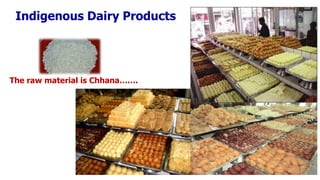

- 1. Indigenous Dairy Products The raw material is Chhana…….

- 3. Chhana

- 5. Chhana refers to the milk-solids obtained by the acid coagulation of boiled hot whole or skim milk and subsequent drainage of whey The acid commonly used are lactic or citric in both natural and chemical forms. According to (PFA, 1976) rules of India, Chhana is the product obtained from cow and buffalo milk or a combination there of by precipitation with sour milk, lactic acid or citric acid. It should not contain more than 70% moisture, and the milk fat content should not be less than 50% of the dry matter. Chhana

- 6. Milk Chhana Fat Protein : Casein Whey Lactose Protein: Soluble Mineral

- 7. Chhana Preparation Whey Separation Chhana

- 8. Rasagolla Rasamalai Kalogam Sandesh Chhanar polao Chomchom Monda Katavog Milk Chhana Fat Protein : Casein

- 9. Rasagolla Rasamalai Kalogam Sandesh Chhanar polao Chomchom Monda Katavog Chhana Fat Protein : Casein Lactose Protein: Soluble Mineral Produce Huge Amount of Whey Drainage of Whey Storage of Whey Present condition in Bangladesh What is the fate of whey Milk

- 11. Types of Chhana On the basis of fat content On the basis of species of milk i) Full fat Chhana or whole milk Chhana ii) Skim milk Chhana or Non-fat Chhana iii) Low fat milk Chhana or Half fat Chhana i) Cow milk Chhana ii) Buffalo milk Chhana

- 12. i) Full fat Chhana or whole milk Chhana: Chhana prepared from whole milk of cow or buffalo or combination of cow and buffalo milk ii) Skim milk Chhana or Non-fat Chhana: Chhana prepared from skim milk of cow or buffalo or combination of cow and buffalo skim milk iii) Low fat milk Chhana or Half fat Chhana: Sometimes Chhana producers mixed skim milk and whole milk together for preparation of this Chhana. Chhana prepared from milk is also known as “ Full fat Chhana. On the other hand Chhana prepared from skim milk is also known as “Non-fat Chhana.” and Chhana prepared from mixture of skim and whole milk is known as “Half-fat Chhana.” On the basis of fat content

- 13. i) Cow milk Chhana: Chhana prepared from cow milk ii) Buffalo milk Chhana: Chhana prepared from buffalo milk On the basis of species of milk

- 14. Type of milk Moisture Protein Fat Lactose Ash Cow 53.4 17.4 24.8 2.1 2.1 Buffalo 51.6 14.4 29.6 2.3 2.0 Composition of Chhana It is observed that the chemical composition of Chhana is influenced by several factors, which are i) Initial composition of milk ii) The condition of coagulation iii) The techniques of straining iv) The loss of milk solids in whey

- 15. Methods of Chhana Production i) Existing Traditional Method a) Batch method b) Bulk method ii) Improved Method

- 18. a) Batch method Boiling of milk in large iron karai on open fire Slowly but continuously stirring of milk with kunti Transfer of hot milk in separate milk coagulation vessel (0.5-1.0 kg capacity) batch by batch Coagulant (sour Chhana whey) are kept earlier in the vessel or added promptly Gradually stirring of milk and coagulant Coagulation complete within one or two min Pouring of the content of coagulated vessel over apiece of muslin cloth stretching over another vessel for receiving the whey Tied up bundle without giving pressure and hanging up for complete drainage of whey Process repeated batch by batch

- 19. b) Bulk method Boiling of milk in karai Stirring of milk with kunti during boiling Milk is taken out from fire after boiling Required amount coagulant is added slowly and gradually to the entry lot of milk Stirring with ladle for proper mixing and continuing upto clear coagulation takes place Coagulated mass is strained by using muslin cloth and hung for some time to drain the whey Storage of Chhana in cool dry place before further processing/marketing

- 21. Improved Method The basic principles involved in Chhana making by improved method is also similar to traditional method but in case of improved method emphasis is given on some following items/points. Such as- A. Equipment used B. Condition of Coagulation C. Quality of milk used D. Method of storage

- 22. Special type of stainless steel Jacketed-Kettle for milk heating cum coagulation has been developed in India. The Jacketed Kettle is capable of rotating sideways around fixed axis. The milk is heated in the kettle by admitting stream into the jacket, the stirring-cum-scraping is usually done with khunti. When milk boils then the stream is stopped and cold water is circulated in the jacket. Simultaneously coagulum (whey) is added in a thin film of stream within 0.5 to 1.0 minute. Content is stirred slowly and coagulation completed within short period of time. When this appear clear then it is removed by straining with the help of thin muslin cloth. Chhana is then hung for a while for complete drainage of whey. A) Equipment:

- 23. (a) pH (and acidity) of coagulation: pH should be around 5.4 for good body and texture. (b) temperature and time of coagulation: Optimum temperature for adding coagulum is about 80 to 82 C and Coagulum should be added with 0.5 to 1.0 minute. (c) Strength of the coagulum/coagulating acid solution: A satisfactory strength of the coagulating acid solution is 1 to 2%. (d) Type of acid: Lactic acid tends to produce a granular texture (suitable for rasogolla) and citric acid tends to produce pasty type Chhana which is suitable for sandesh making. (e) Speed with which the milk is stirred for mixing the coagulating acid: To avoid foam formation slow stirring is preferable. If foam is produced due to vigorous stirring, it obstructs the visibility of the clear whey during coagulation. (B) Conditions of coagulation The body and texture of Chhana is influenced by the conditions of coagulation which include:

- 24. (a)Type of milk: Cow milk is suitable for chhana making, as because soft chhana is obtained from this milk. But quality rasogolla and sandesh including monda could be made from cow milk chhana. On the other hand buffalo milk produce slightly hardy, greesy and coarse texture unless the milk is pre-treated. (b) Fat percentage of milk: A minimum fat level of 4% in cow and 5% in buffalo milk is necessary to produce good quality chhana. Low fat level than above mentioned in milk results in a hard body and coarse texture. A high fat level is also not desirable because it produces greasiness in the chhana sweets prepared from it. (C) Quality of milk. This also influences the body and texture of Chhana. Under this factor are included-

- 25. (c) Acidity of milk: Fresh sweet milk produces the best chhana. Any developed acidity tends to produce on undesirable sour smell and a bitter taste, which makes it unsuitable for sweet preparation. Sometimes neutralizers are added in slightly acidic milk and chhana is prepared from it. Quality of this type of Chhana may be acceptable for sandesh making but not for monad or good quality rasogolla. (d) Adulteration of milk: Adulteration of milk with starch results in gelatinous mass on coagulation which is not suitable for sweetmeat preparation. (e) Presence of colostrum: The presence of colostrum in milk tends to produce a pasty texture in the coagulated mass, which jeopardizes its suitability for sweet-making.

- 26. Method of Straining Method of straining can influence the quality of Chhana. Usually two types of straining operation for removal of whey from Chhana is practiced by Chhana makers. 1. Straining of Chhana just after coagulation: hung the chhana just after coagulation and hung the chhana in muslin cloth for drainage of whey and subsequently cooling of chhana. 2. Keeping chhana for long time in the coagulated vessel together with whey until the chhana become completely cool: there after whey is drained out by using the same way. Due to delay straining more moisture retained in chhana. But immediate straining produces chhana with less moisture and more dry matter content.

- 27. Production of Chhana from buffalo milk Buffalo contain high level of fat and the size of fat globules of buffalo milk is larger than buffalo milk. It has been observed that chhana from buffalo milk has a slightly hard body and greasy and coarse texture and dose not produce good quality chhana sweets. For this reason some techniques are necessary for production of good quality chhana from buffalo milk.

- 28. Procedure: Filter of fresh buffalo milk Standardized at 5% fat Preheated at 60 C Homogenize milk at 176 kg/ sq. cm Boiling of milk and promptly cool to 70 C Adding of required amount of coagulum for complete coagulation Keeping of coagulated mass i.e. chhana in the vessel for sometimes to bring the mass at room temperature Drainage of whey by delay straining method

- 29. Distribution of milk constituent in Chhana and Whey Milk Constituents Percentage Distribution Cow Buffalo Chhana Whey Chhana Whey Milk fat 90 10 85 15 Milk Protein 89 11 91 09 Lactose 07 93 12 88 Mineral salts 48 52 60 40 Total solids 58 42 65 35 Solids-not-fat (SNF) 42 58 48 52

- 30. Marketing quality of Chhana i) Physical quality ii)Chemical quality iii)Microbiological quality

- 31. i) Physical quality of milk obtained from cow and buffalo milk Parameters Cow Milk Chhana Buffalo Milk Chhana Color Light yellow Whitish Appearance Moist surface Greasy surface Body soft Slightly hard Texture Smooth Slightly coarse Flavour Mildly acid Mildly acid Suitability for sweets Highly suitable Not suitable (when made without pre-treatment of milk) The above mentioned physical quality of chhana mainly depends on: i) The type of milk used ii) Condition of coagulation iii) Techniques of straining

- 32. The Chhana which are available in local market of Bangladesh are mainly prepared from cow milk and processes following characteristics: i) Should have an uniform light-yellow color ii) A slightly moist surface iii)A soft body and smooth texture iv)A mildly acid flavour v) Free from off-flavour, foreign particles and moulds

- 33. ii) Chemical quality of Chhana Chemical quality of chhana is evaluated on the basis of chemical composition. Good quality chhana will fulfil the requirements of composition of chhana. At the same time it should neither contain any foreign to milk nor be adulterated.

- 34. iii) Microbiological quality of Chhana At the present moment no microbiological standard of chhana is available. It should be bear in mind that for making chhana milk is heated to boiling temperature and during that no bacteria should survive in milk except spore former (if present). Bacteria can gain entrance in Chhana during straining, storage and transportation. It is advisable to maintain strict hygienic condition during Chhana processing. Keeping quality of hygienically produced chhana will be higher than that of the un hygienically produced chhana due to variation in bacterial population. Hygienically produced chhana will contain less bacteria.

- 35. In order to maintain low bacterial count in Chhana the following points should be consider during chhana making and processing i) Chhana making place should be clean dry and free from volatile odour ii) All equipment used in the process should be cleaned iii) After each operation every equipment should be cleaned and dried properly iv) Muslin cloth used for straining should always be kept clean and dry v) After straining chhana should be stored in cool and dry place. If possible it is better to keep in refrigerator. vi) Clean and safe water should be used for washing equipment used in chhana making vii) Hands of chhana makers should be washed nicely with soap before starting chhana making

- 36. Yield of Chhana Yield of Chhana is variable. Its yield depends on several factors, such as i) Total solid content of milk, specially fat and casein content ii) The amount of moisture retained in chhana iii) Losses of milk solid in whey In Bangladesh 7-8 kg Chhana is produced from 40 kg of milk. Thumb rule Chhana contain 49-54% moisture Yield for cow milk : 16-18% of total milk Yield for buffalo milk : 22-24% of total milk

- 37. Packaging, Storage and Marketing of Chhana (A) Packaging: At present chhana producers do not use any modern system for packaging Chhana. For transport from one place to another they usually use bamboo made baskets with leaf linings. Sometimes they use wet cloth as linings materials in bamboo baskets. Chhana in the basket is covered with moist cloth to kept it cool. In order to maintain the quality in of chhana in maketing and transportation from one place to another modern packaging system by using food grade polyethylene or plastic should be developed.

- 38. (B) Storage: Since chhana stored at room temperature has a very low keeping quality, refrigerated storage (5-10০ C) is preferable. (C) Marketing: This is at present generally done soon after production in an unpacked or crudely packed condition, depending on the distance of the market.

- 39. (a)The storage temperature: the keeping quality of chhana under ordinary packaging is on an average 2, 3 and 12 days at 37 C, 24 C, and 7 C, respectively. (b) Quality of the raw material (milk): keeping quality of chhana made from fresh, sweet milk has been reported to be 5-6days at 5-10 C while made from slightly acidic milk seems to have a storage life of 3-4 days at the same temperature. (c) Initial moisture content: Moisture always help further growth of bacteria. For this reason keeping quality of Chhana having high level of moisture is lower than that of the chhana having low level of moisture. (d) Sanitary conditions observed during manufacture: Improved sanitary condition during manufacturing process helps to keep bacterial population at low level and keeping quality increases. On the other hand poor sanitary condition increases bacterial number in Chhana and keeping quality of that types of Chhana decrease. Keeping quality: The keeping quality of chhana/paneer is mainly influenced by: Keeping quality of Chhana

- 40. Defects in Chhana, their causes and prevention Defects Causes Prevention Smoky Smoky fire used for boiling and simmering of milk. Using non-smoky fire for boiling and simmering of milk. Sour (1) Excessive acidity in milk used (2) Excessive amount of coagulating acid/sour-whey used. (1) Optimum acidity in milk used (preferably fresh,sweet milk) (2) Using proper amount of coagulating acid/sour whey Rancid Fat hydrolysis due to lipase action in chhana during storage(at room temperature or above). Storage of chhana at low temperature (5-10 C) Stale Excessively long period of storage of chhana at low temperature (5-10০C). Early disposal/ marketing of chhana. (a) Flavour

- 41. (b) Body and texture Defects Causes Prevention Hard body (1)Inadequate fat content in milk used. (2) Inadequate moisture content of chhana, due to faulty production technique. (1)Optimum fat content in milk used. (2) Proper moisture content of chhana by adopting correct production technique. Coarse texture (1)Excessive acidity in milk used. (2) Inadequate fat content in milk used. (3) Improper (too-high) temperature of coagulation. (4)Improper (too-low) pH of coagulation. (1)Proper acidity in milk used (preferably fresh, sweet milk) (2) Optimum fat content in milk used. (3) Optimum temperature of coagulation. (4) Proper pH of coagulation.

- 42. (C ) Colour and appearance Defects Causes Prevention Dry surface Excessive fat content in milk used. Optimum fat content in milk used Surface skin Surface of chhana exposed to atmospheric air. (1) Chhana kept steeped in whey (2) Air-tight packing used. Visible dirt/ foreign matter (1)Incorrect or no straining of milk. (2) Milk-boiling and/or coagulation vessel not cleaned. (3) Dirty/windy surroundings during manufacture and/or handling of chhana. (4) Transport of unpacked chhana. (1) Correct straining of milk (2) Milk-boiling and/or coagulation vessel well cleaned (3) Clean surroundings during manufacture and/or handling of chhana (4) Transport of packed chhana. Mouldy surface (1) Long storage of chhana, especially in humid atmosphere (2) Excessive moisture content in chhana. (1) Early disposal/marketing of chhana (2) Optimum moisture content in chhana