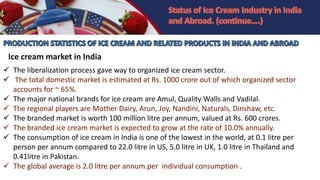

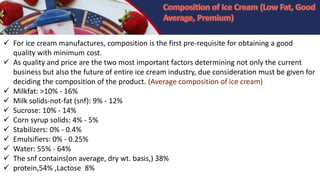

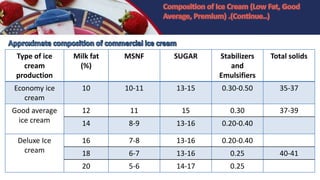

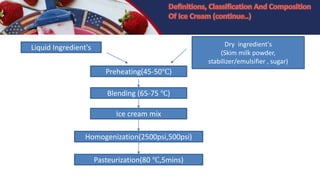

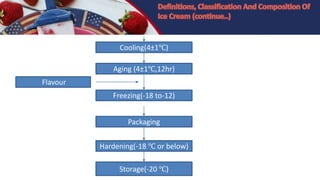

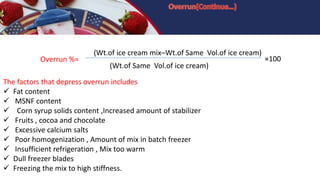

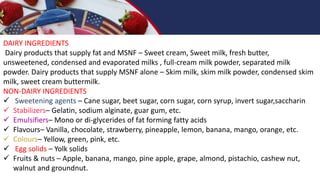

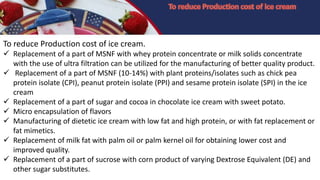

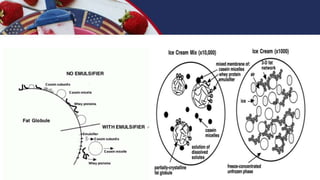

This document discusses the history and production process of ice cream. It traces the origins of ice cream back to ancient times when iced beverages were popular. Marco Polo is credited with introducing ice cream to Italy after returning from China in the 13th century. Over subsequent centuries, recipes evolved with the addition of ingredients like cream. Modern ice cream production involves carefully selecting ingredients, formulating the mix, blending, homogenizing, pasteurizing, aging, and freezing the mix before packaging and hardening. Key aspects like fat content, MSNF, sweeteners, emulsifiers and stabilizers are considered for achieving good quality and texture.