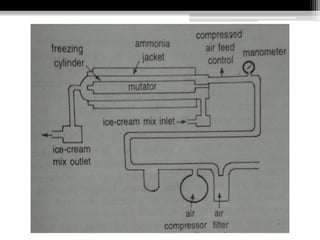

Freezing is a key step in ice cream production that incorporates air into the mix to give it a light, creamy texture. There are two main types of freezers - batch and continuous. Batch freezers freeze individual batches while continuous freezers continuously feed and freeze the mix. Both utilize a freezing cylinder and dasher to freeze and incorporate air into the mix, though continuous freezers operate under pressure. Proper freezing results in small ice crystals that give ice cream a smooth body and texture.