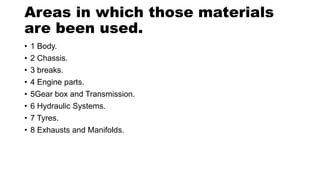

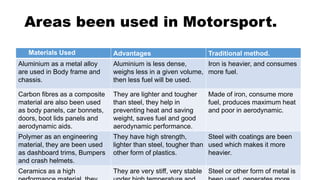

High performance engineering materials are introduced to improve properties like strength, heat and corrosion resistance, and sustainability. Examples include polymers used in plastics, composite materials like carbon fiber, metal alloys such as aluminum and steel, and ceramics. These materials are used in areas like vehicle bodies, engines, and brakes due to properties like light weight, high strength, and stability at high temperatures. Their use increases engineering performance and reduces environmental impact compared to traditional materials.

![REFERENCES.

• Composite Materials for Automotive & Motorsport applications | PRF

Composites. 2015. Composite Materials for Automotive & Motorsport

applications | PRF Composites. [ONLINE] Available

at:http://www.prfcomposites.com/industries/motorsport [Accessed 02 October

2015].

• Google. 2015. Google. [ONLINE] Available at:

http://www.google.co.uk/webhp?sourceid=chrome-

instant&rlz=1C1FERN_enGB628GB628&ion=1&espv=2&ie=UTF-

8#q=high%20performance%20engineering%20materials%20wikipedia.

[Accessed 02 October 2015].

• Home | Federal Highway Administration. 2015. Home | Federal Highway

Administration. [ONLINE] Available at: http://www.fhwa.dot.gov/. [Accessed

02 October 2015].

• Home - Michigan State University. 2015. Home - Michigan State

University. [ONLINE] Available at: http://www2.chemistry.msu.edu.](https://image.slidesharecdn.com/7e820bd6-9047-490c-b9f7-c9b477e9e35d-160416191646/85/High-Performance-Engineering-Materials-11-320.jpg)