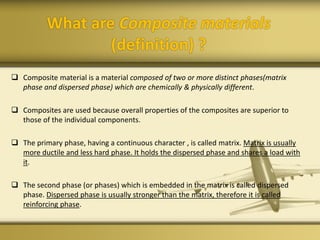

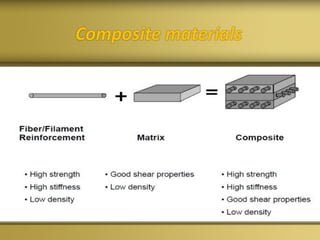

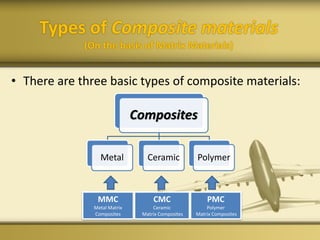

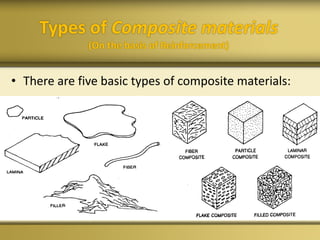

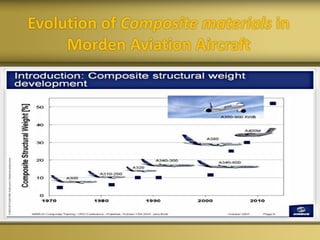

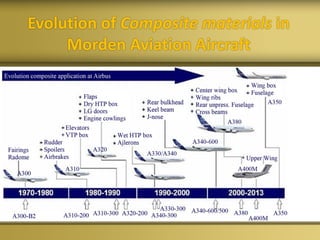

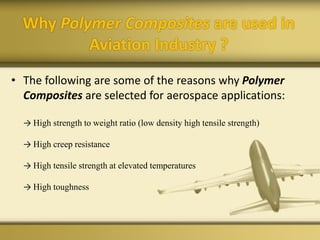

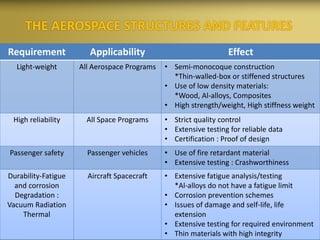

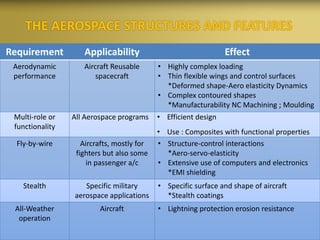

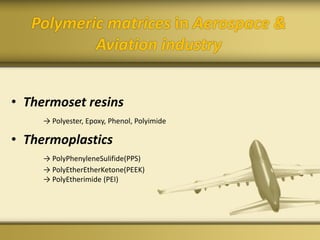

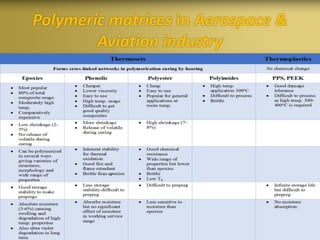

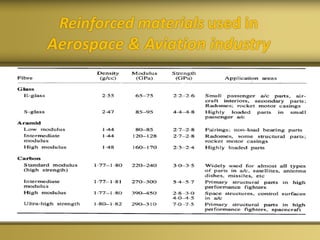

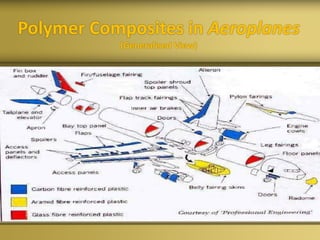

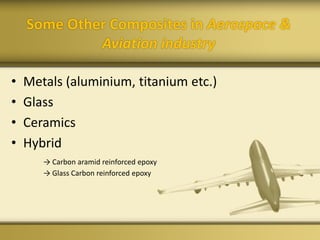

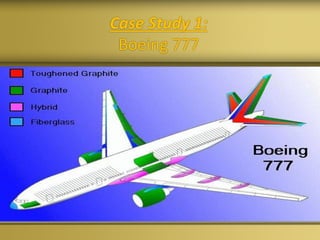

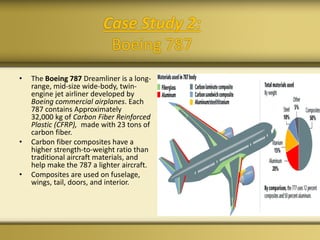

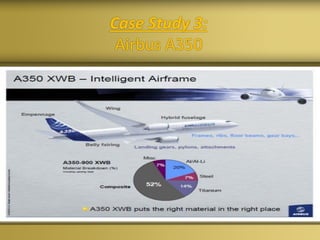

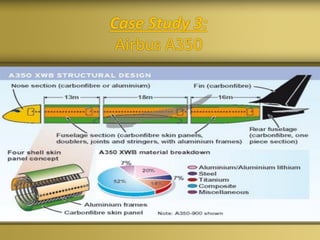

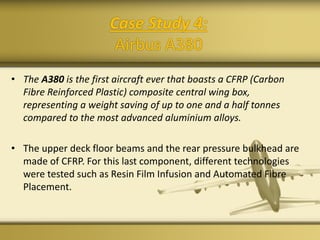

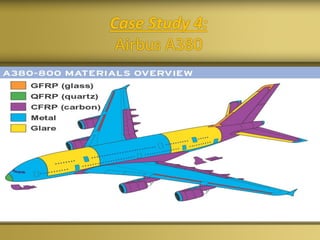

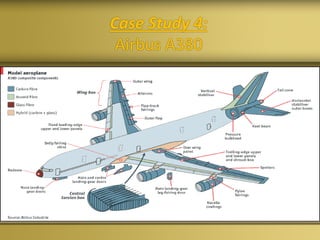

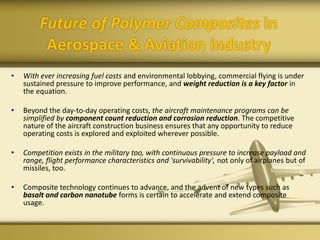

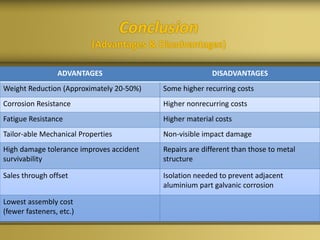

The document presents a seminar on the role of polymer composites in the aviation industry, detailing their definitions, evolution, performance benefits, and current applications in modern aircraft. It discusses significant case studies such as the Boeing 777, 787, and Airbus A350, highlighting the advantages of using composite materials, including weight reduction and corrosion resistance. The future prospects of polymer composites are framed within the context of increasing demands for efficiency and performance in aerospace design and maintenance.