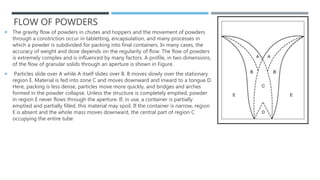

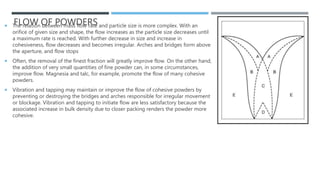

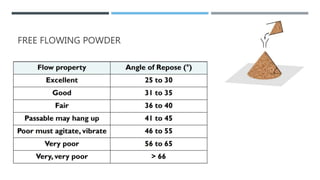

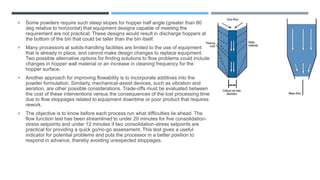

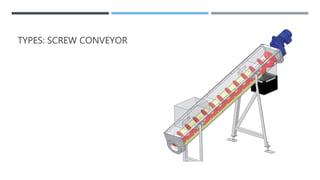

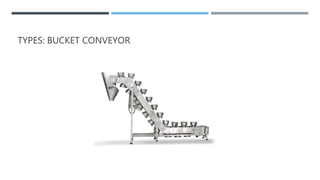

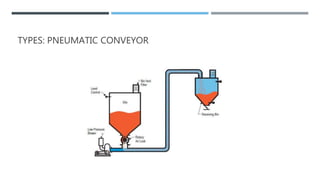

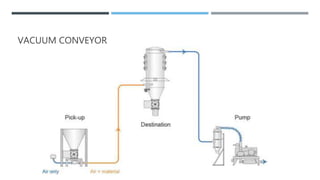

This document discusses principles and methods for handling solids in pharmaceutical engineering. It begins by describing different types of solids like powders, granules, and how their properties like cohesiveness, moisture content, and particle size affect flow. It then discusses various methods for handling solids including different types of conveyors, bins, vacuum systems. Specific conveyor types covered are belt, screw, bucket, and pneumatic conveyors. Factors affecting powder flow like shape, moisture and methods to improve flow like granulation, vibration are also summarized.