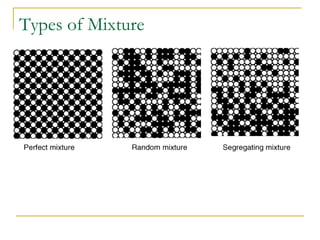

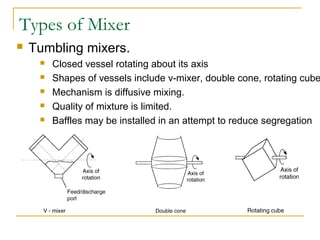

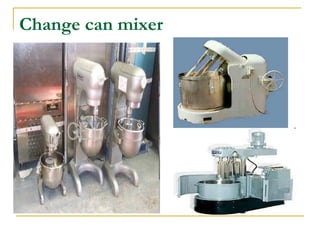

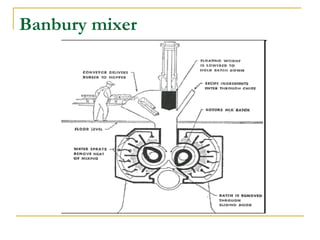

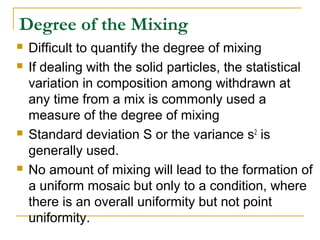

This document discusses mixing in industrial processes. It defines mixing as manipulating a heterogeneous system to make it more homogeneous by intermingling two or more separate components. The types of mixing covered include different materials like solids, liquids, and gases. The mechanisms of mixing include shear, diffusive, and convective mixing. Common mixers are tumbling mixers, convective mixers, ribbon blenders, and others. Factors that impact mixing include mixer selection, mixing time, power consumption, and degree of mixing achieved. Agitation is also discussed and compared to mixing.