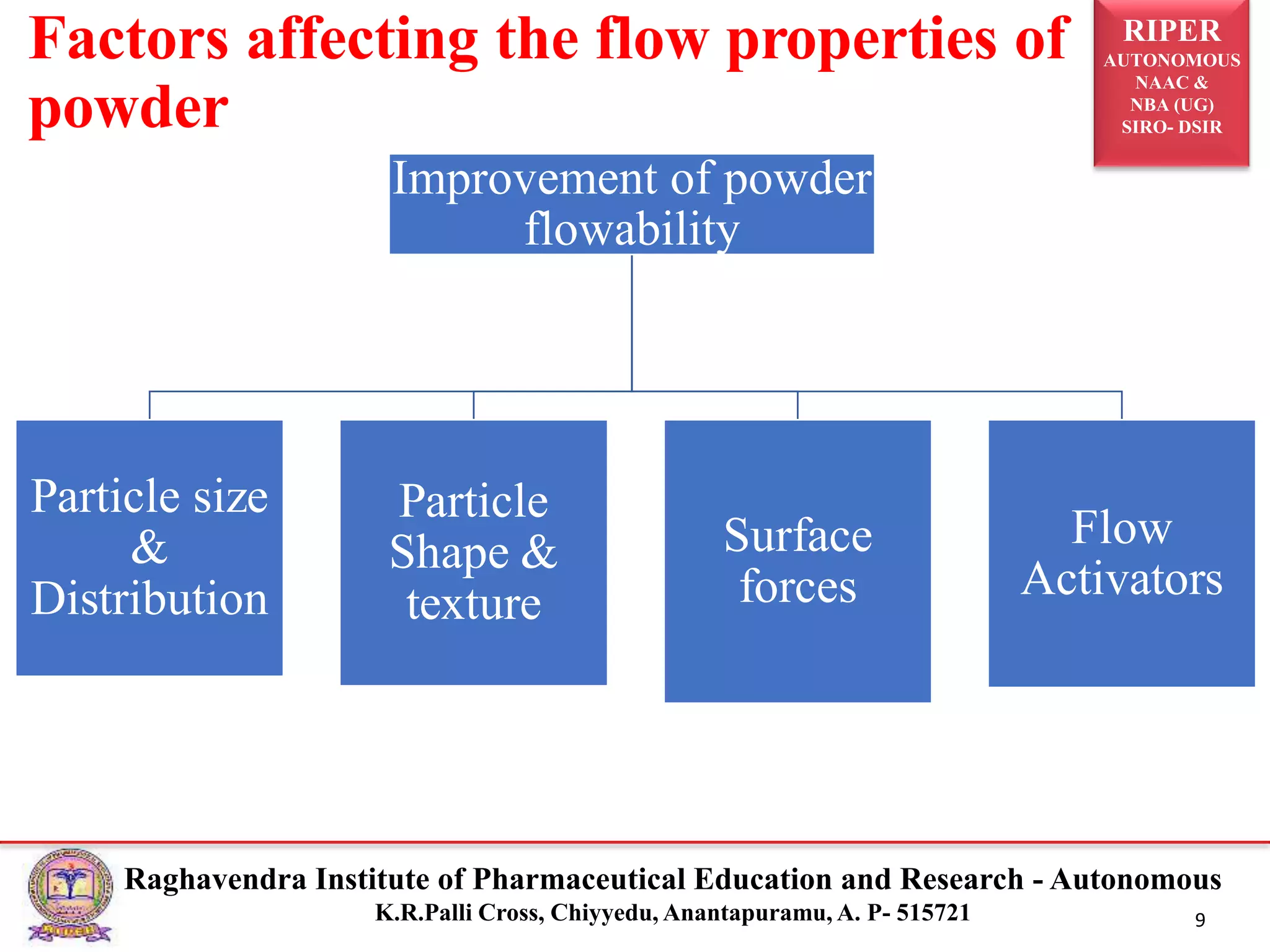

The document is a seminar presentation on powder flow properties relevant to pharmaceutical manufacturing, discussing factors that affect flowability such as particle size, shape, texture, and surface forces. Key methods for characterizing powder flow include Carr's compressibility index, Hausner's ratio, and angle of repose, with recommendations for using flow activators to enhance flow. The presentation also highlights the importance of optimizing powder characteristics for improved manufacturing processes.