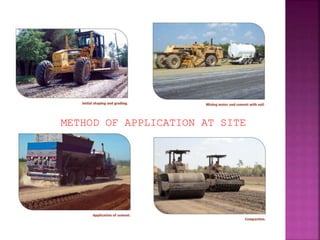

This document discusses various methods for soil stabilization, including different types of admixtures and their uses. It covers cement, bitumen, lime, and other chemical stabilizers. Specific application methods are described for different soil stabilization techniques including cement modified soil, cement treated base, and full depth reclamation using cement. Recommendations for soil properties and chemical proportions are provided for effective stabilization.