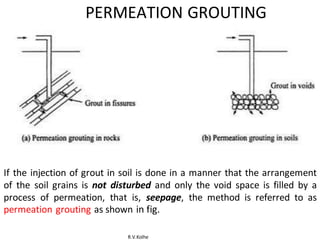

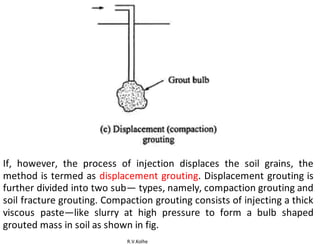

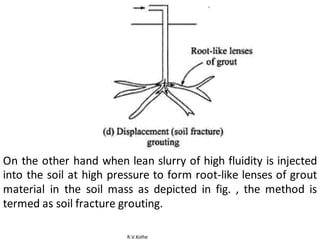

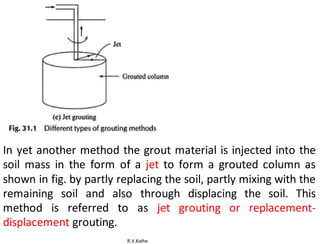

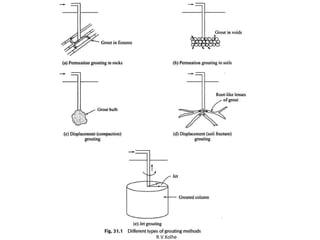

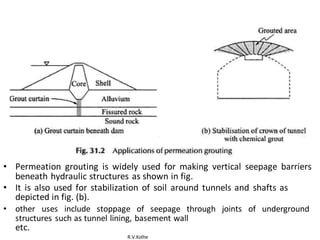

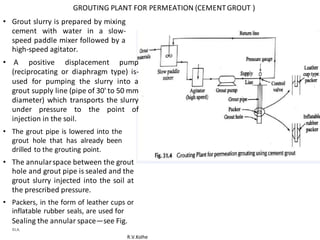

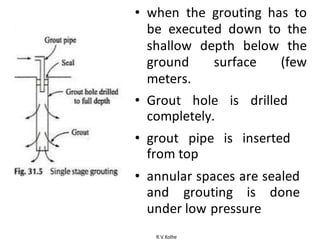

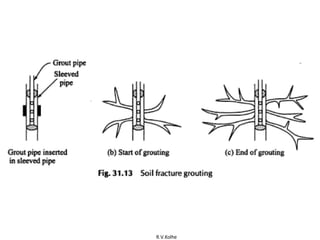

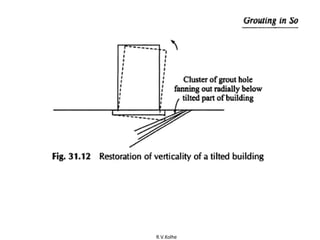

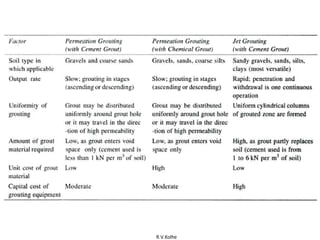

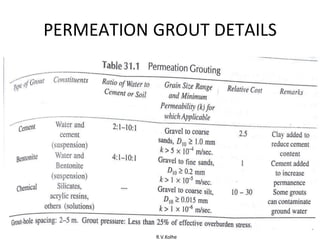

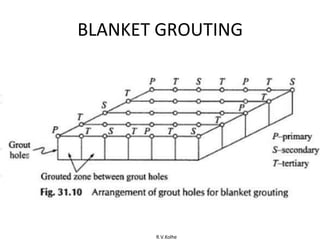

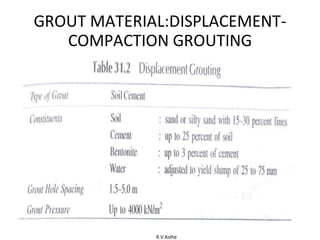

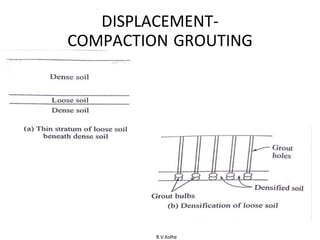

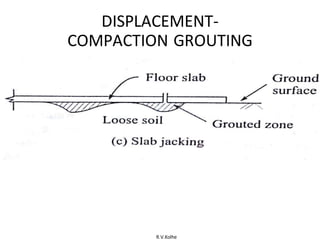

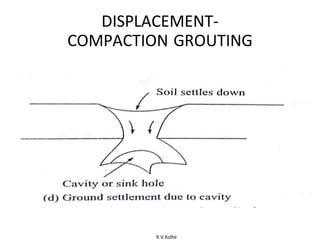

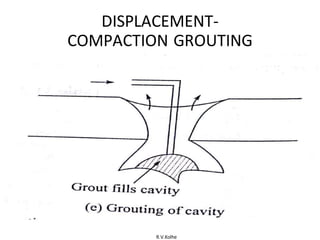

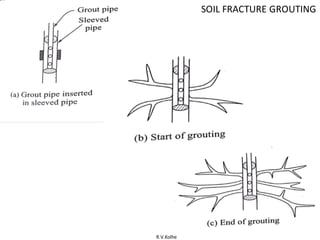

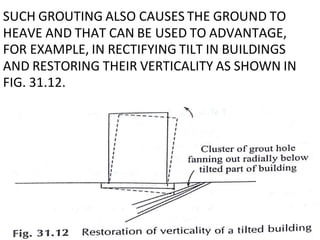

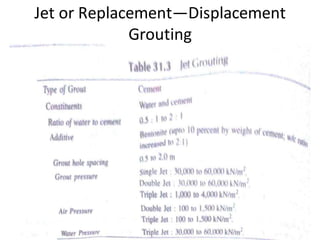

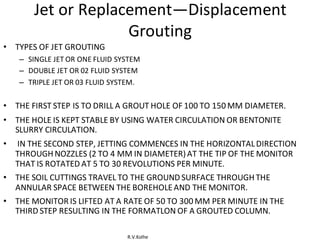

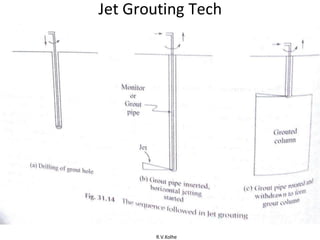

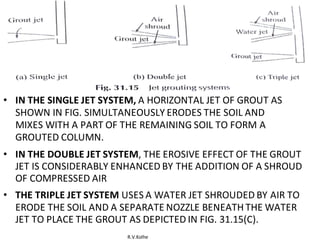

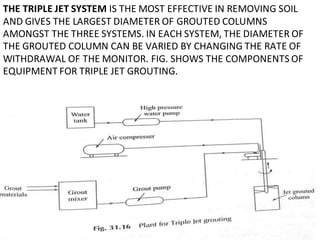

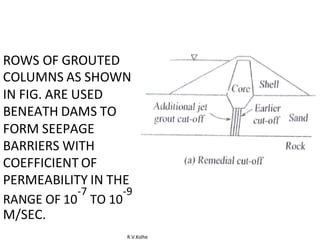

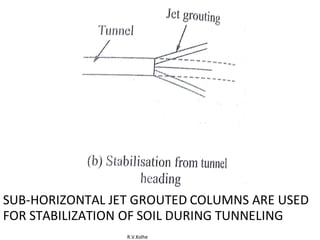

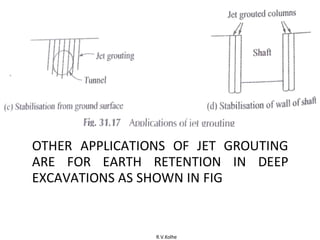

This document discusses different grouting methods. It describes permeation grouting where grout is injected to fill voids without disturbing soil grains. Displacement grouting displaces soil grains, including compaction grouting using thick grout to form bulb shapes, and soil fracture grouting using lean grout to form root-like lenses. Jet grouting forms grouted columns by partly replacing and mixing with soil. Permeation grouting is used to form seepage barriers and stabilize tunnels. Displacement-compaction grouting involves high pressure injection of a soil-cement grout mixture to form 0.5-1m bulbous intrusions.