The document presents an overview of soil stabilization techniques using cement and lime, detailing construction methods, advantages, and disadvantages of each technique. It includes a case study on the in-situ stabilization of a road base in Malaysia, highlighting design parameters, compressive strength results, and empirical relationships derived from field tests. The findings indicate significant improvements in structural capacity and provide insights for monitoring the performance of stabilized layers.

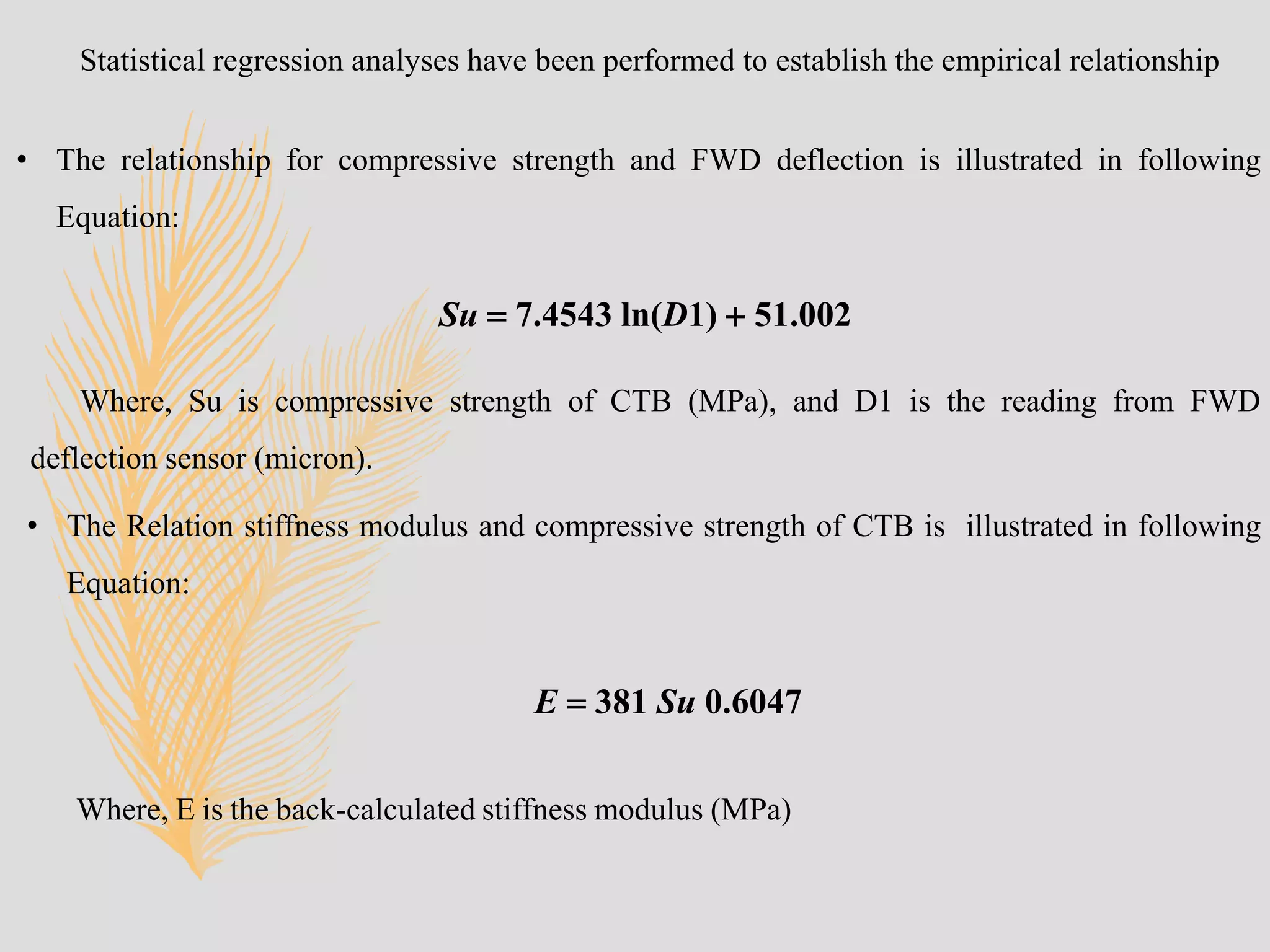

![Age

at

test (days)

In-situ compressive strength (MPa)

from core samples

In-situ compressive

strength (MPa) from

cube specimens

1 - 3

3 - 5.5

4 4.5 -

7 - 6.0

8 6.0 -

29 7.5 -

Table : Compressive strength of the CTB layer

[Source: G. W. K. Chai et al (2005)]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-14-2048.jpg)

![Falling Weight Deflectometer (FWD) was adopted to determine the in-situ stiffness of the

cement stabilized road base material.

Figure : Falling weight deflectometer (FWD)

[Source: researchgate.net]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-15-2048.jpg)

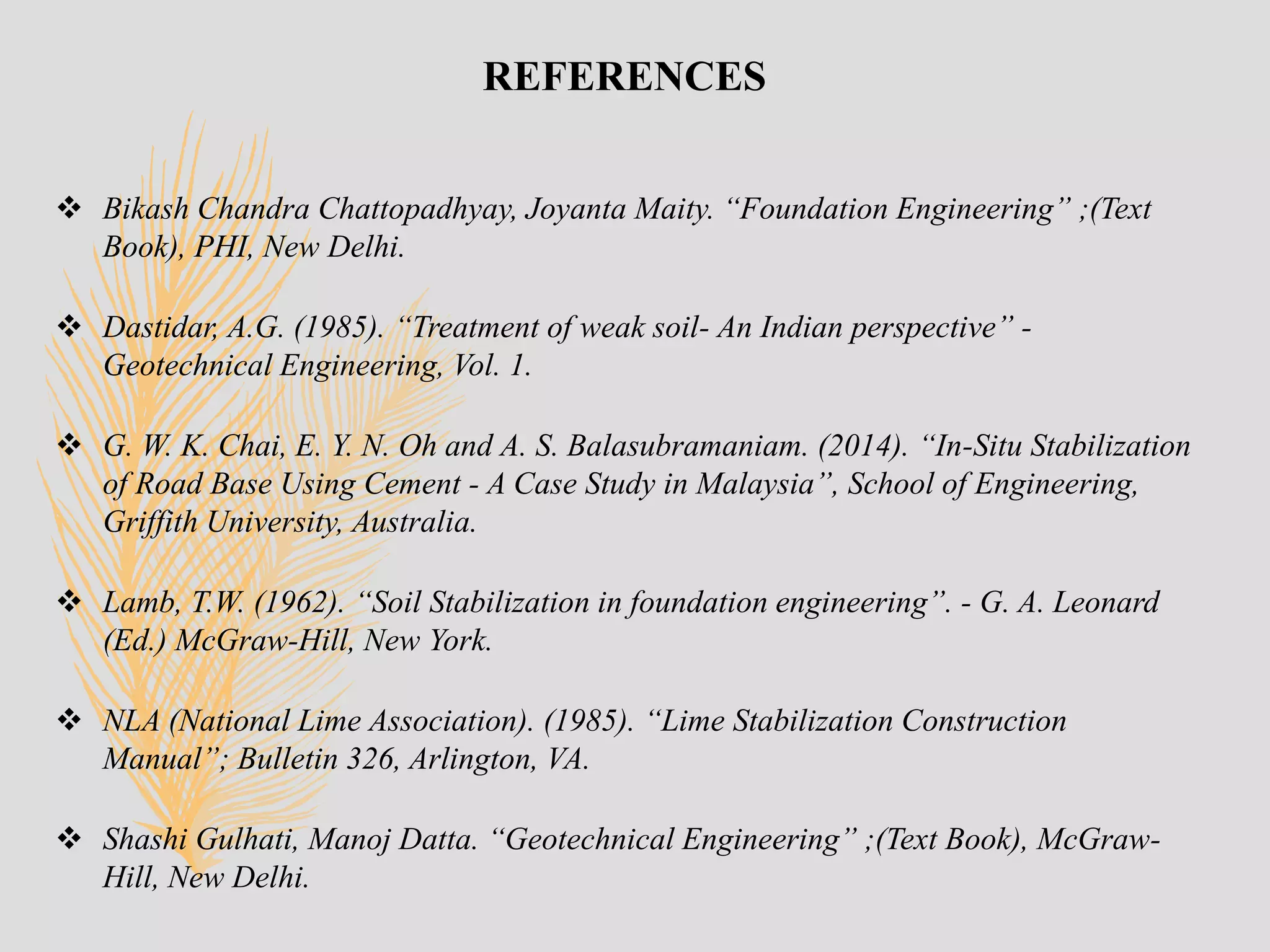

![• Normalized deflection readings were measured by geophones at distances (0, 300mm,

600mm, 900mm, 1200mm, 1500mm and 2100mm) from the center of the loading

plate

• FWD test:

Center deflection reading of 900 microns at 85 percentile value.

For tests performed on the CTB, center deflection value at 85 percentiles for the 3

and 7 days are 500 micron and 400 microns, respectively.

Center deflection at 85 percentile gives a value of 300 micron for 28 days cure.

Figure : FWD center deflection profiles before and after cement stabilization

A: (3 and 7 days); B: (28 days)

[Source: G. W. K. Chai et al (2005)]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-16-2048.jpg)

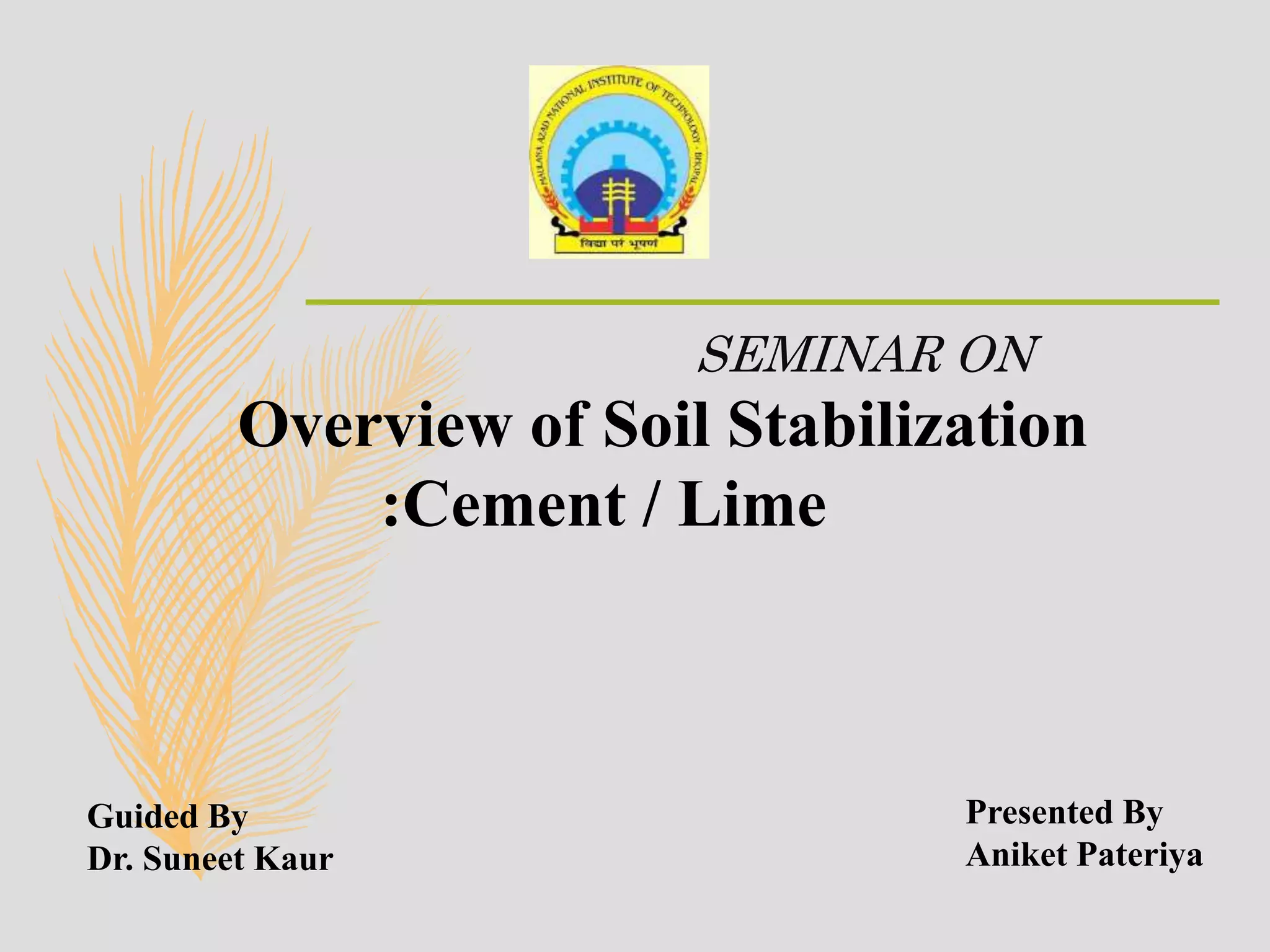

![Test stages Effective stiffness modulus (MPa)

at 85 percentile values

Pavement Layers CTB Road base

Granular Road base

Before Recycling

- 280

CTB after 3 days 700 -

CTB after 7 days 1150 -

Asphalt Surface after

28 days

1350 -

Table : Effective stiffness modulus of the CTB layer

[Source: G. W. K. Chai et al (2005)]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-17-2048.jpg)

![Figure : Compressive strength and deflection D1 relationship from FWD.

[Source: G. W. K. Chai et al (2005)]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-18-2048.jpg)

![Figure : Stiffness modulus and compressive strength relationship from field test

[Source: G. W. K. Chai et al (2005)]](https://image.slidesharecdn.com/soilcementshort-190403110130/75/Overview-of-Soil-Stabilization-Cement-Lime-PPT-19-2048.jpg)