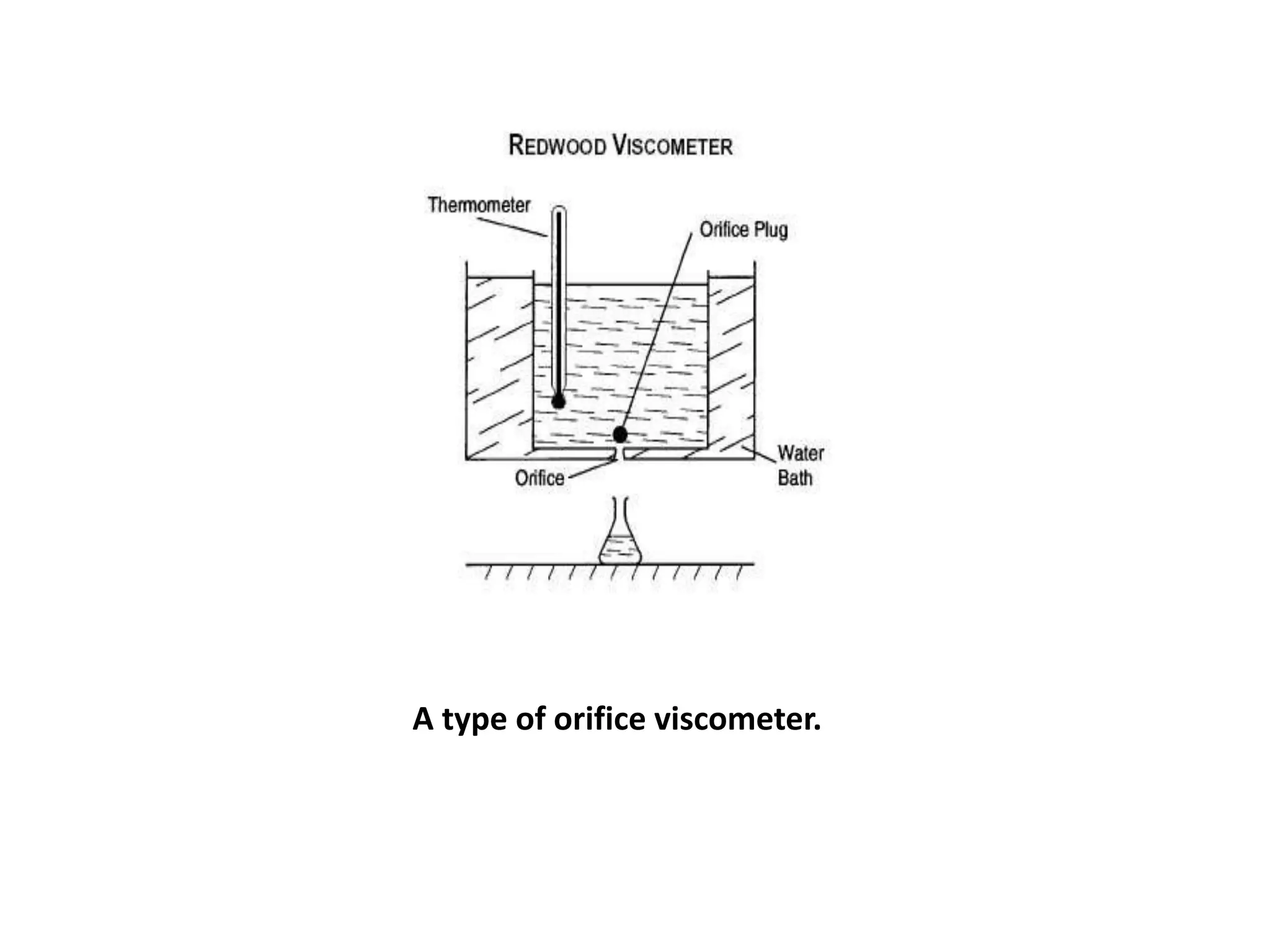

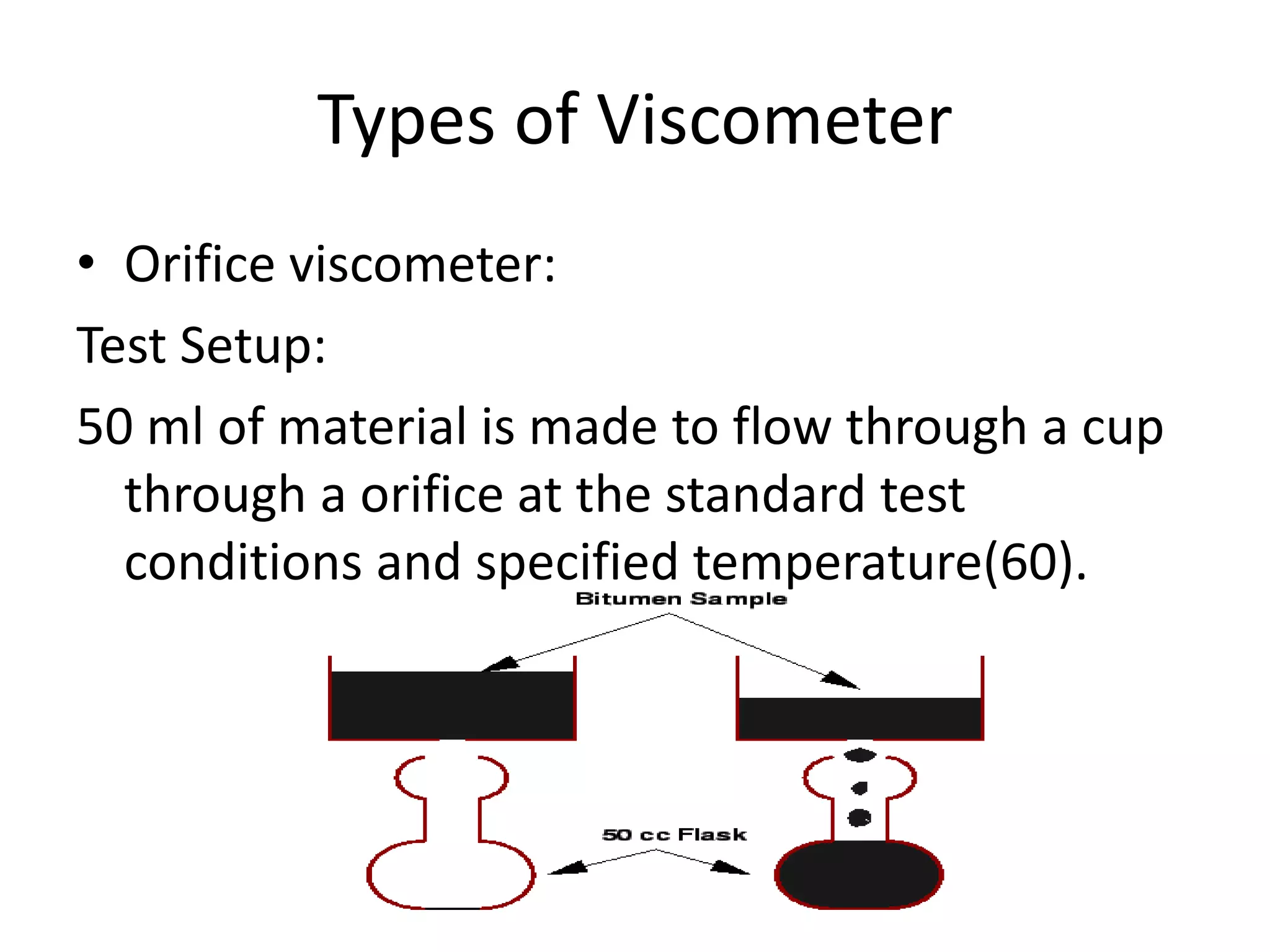

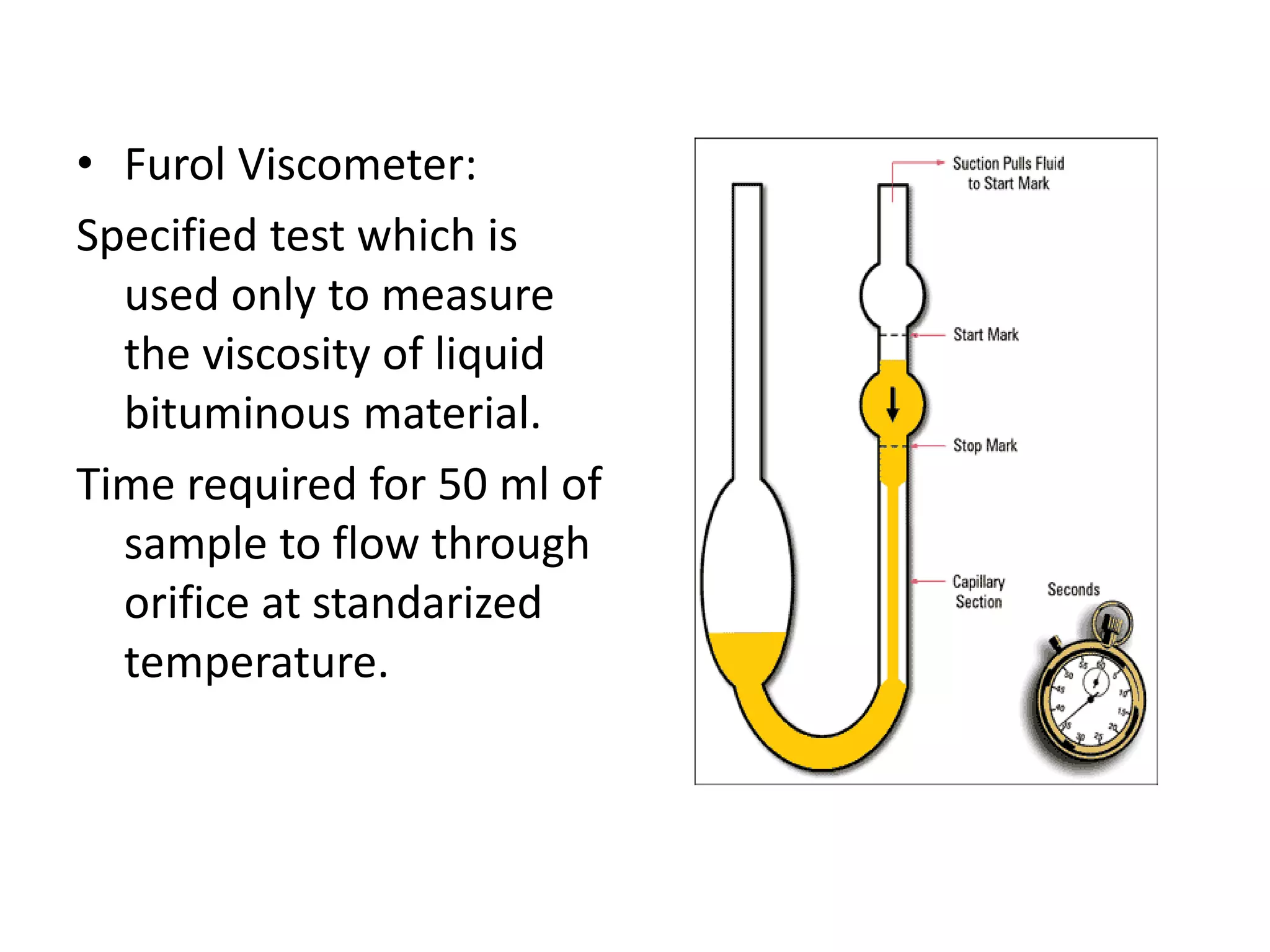

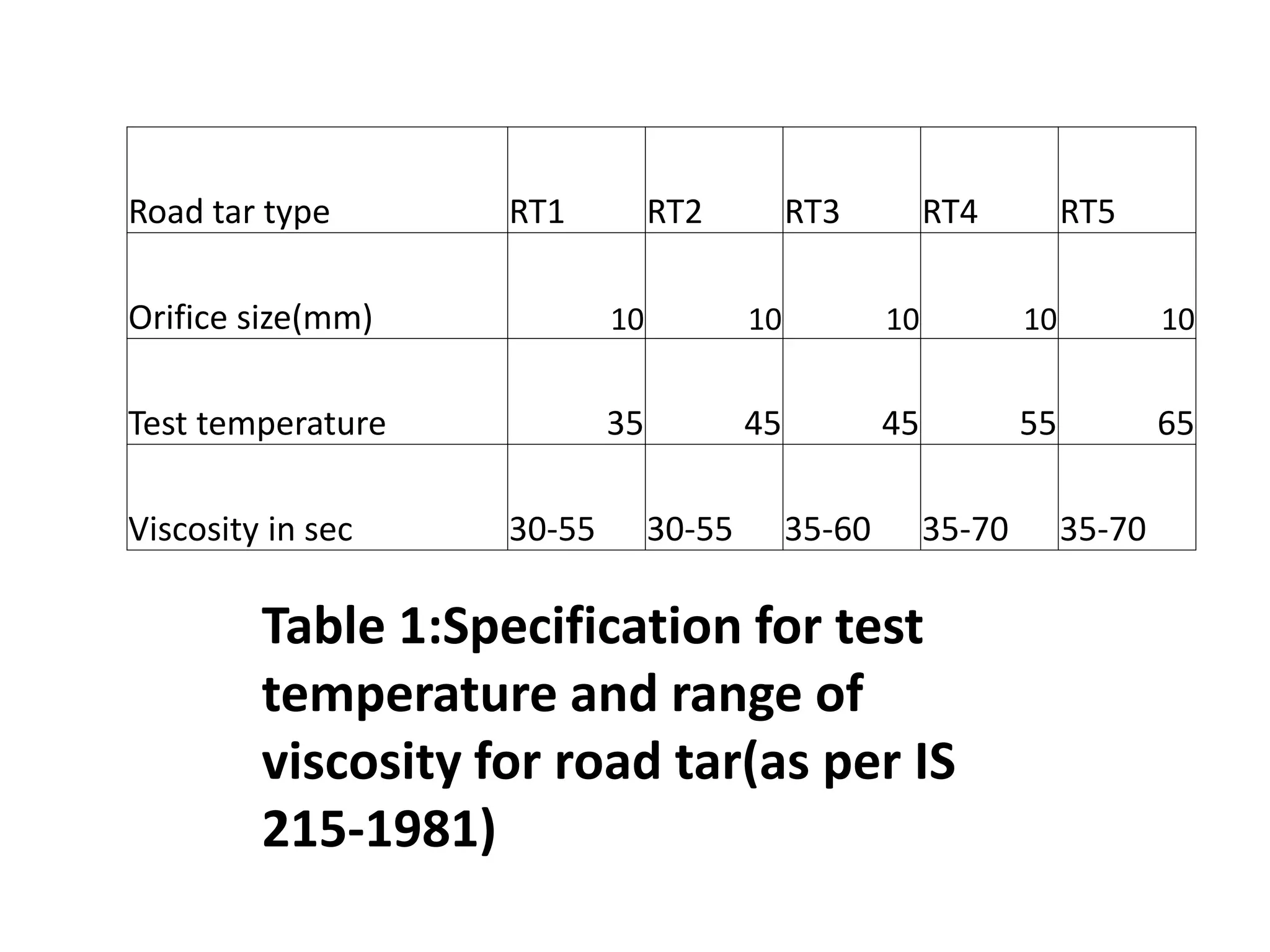

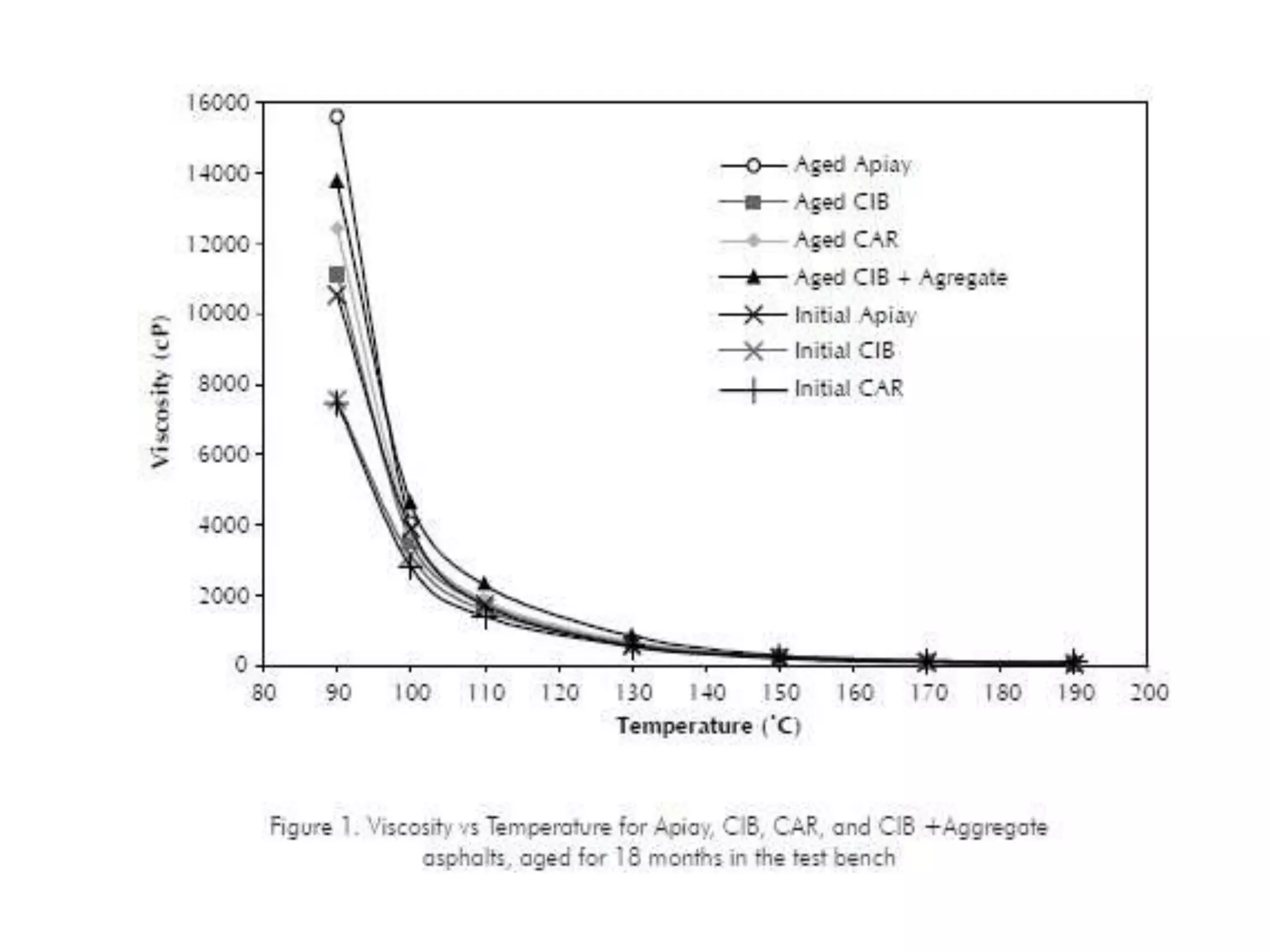

This document discusses viscosity testing for bitumen used in road pavements. It defines viscosity as the resistance to flow and explains that viscosity testing determines the consistency and strength of bitumen at different temperatures. The document outlines different types of viscometers used to measure the time required for bitumen to flow through an orifice at standardized temperatures, and how the results are interpreted to select bitumen with an appropriate viscosity for use in road construction and maintenance.