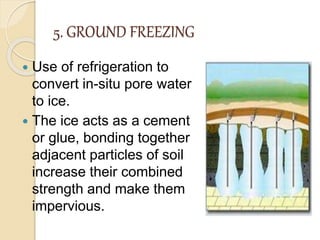

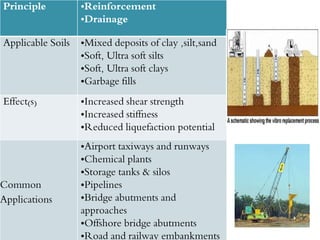

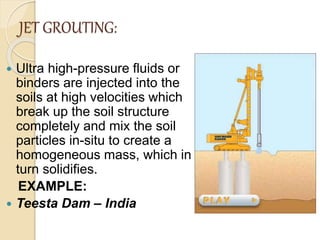

The document discusses various ground improvement techniques essential for accommodating rapid urban and industrial growth, including methods like vibration with water saturation, vacuum consolidation, heating, and ground freezing. It highlights the effectiveness of these techniques in enhancing soil stability and strength, applicable to various soil types and construction projects. Additionally, it emphasizes the cost-effectiveness and time-saving benefits of these methods for successful project completion.