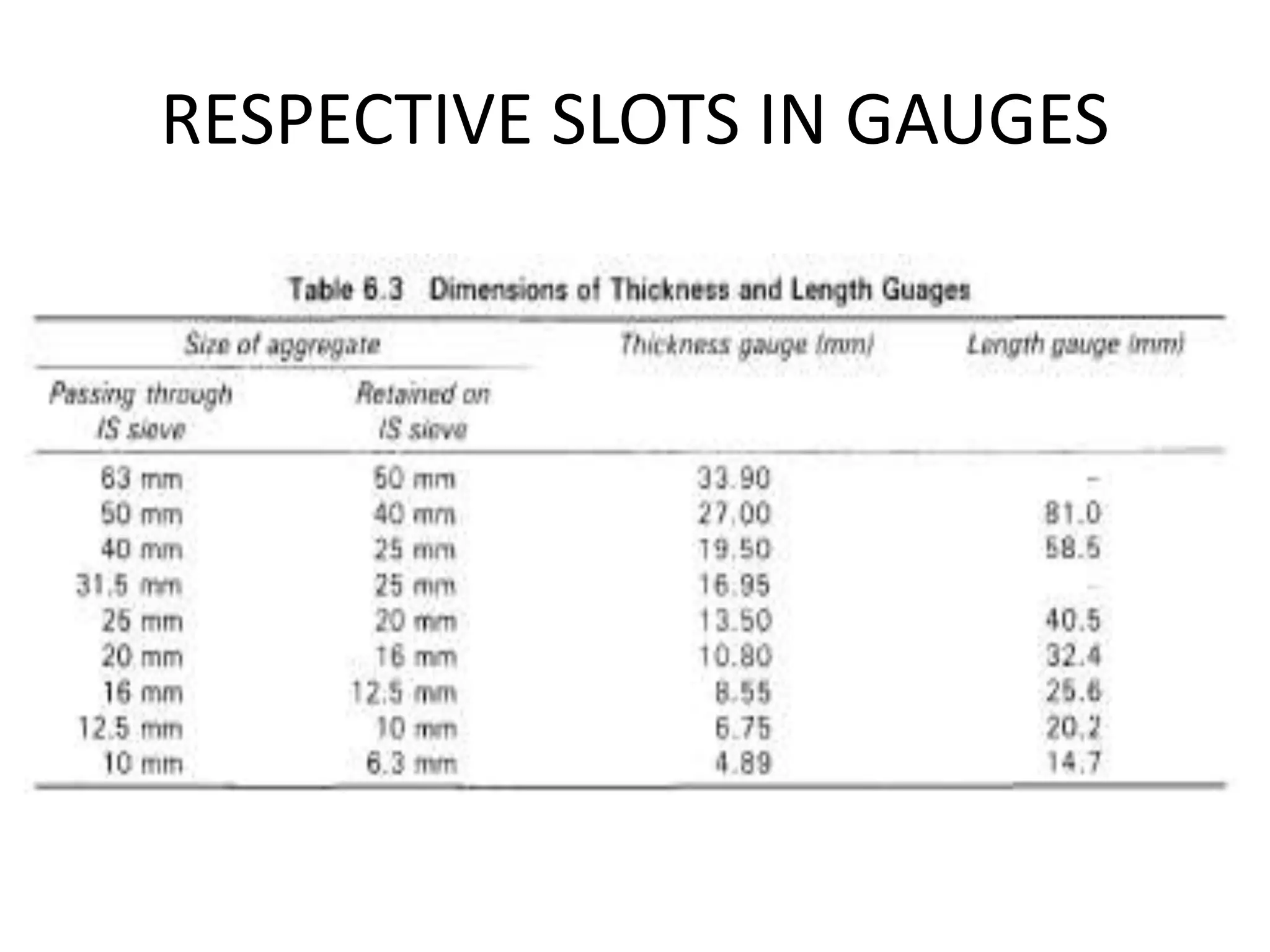

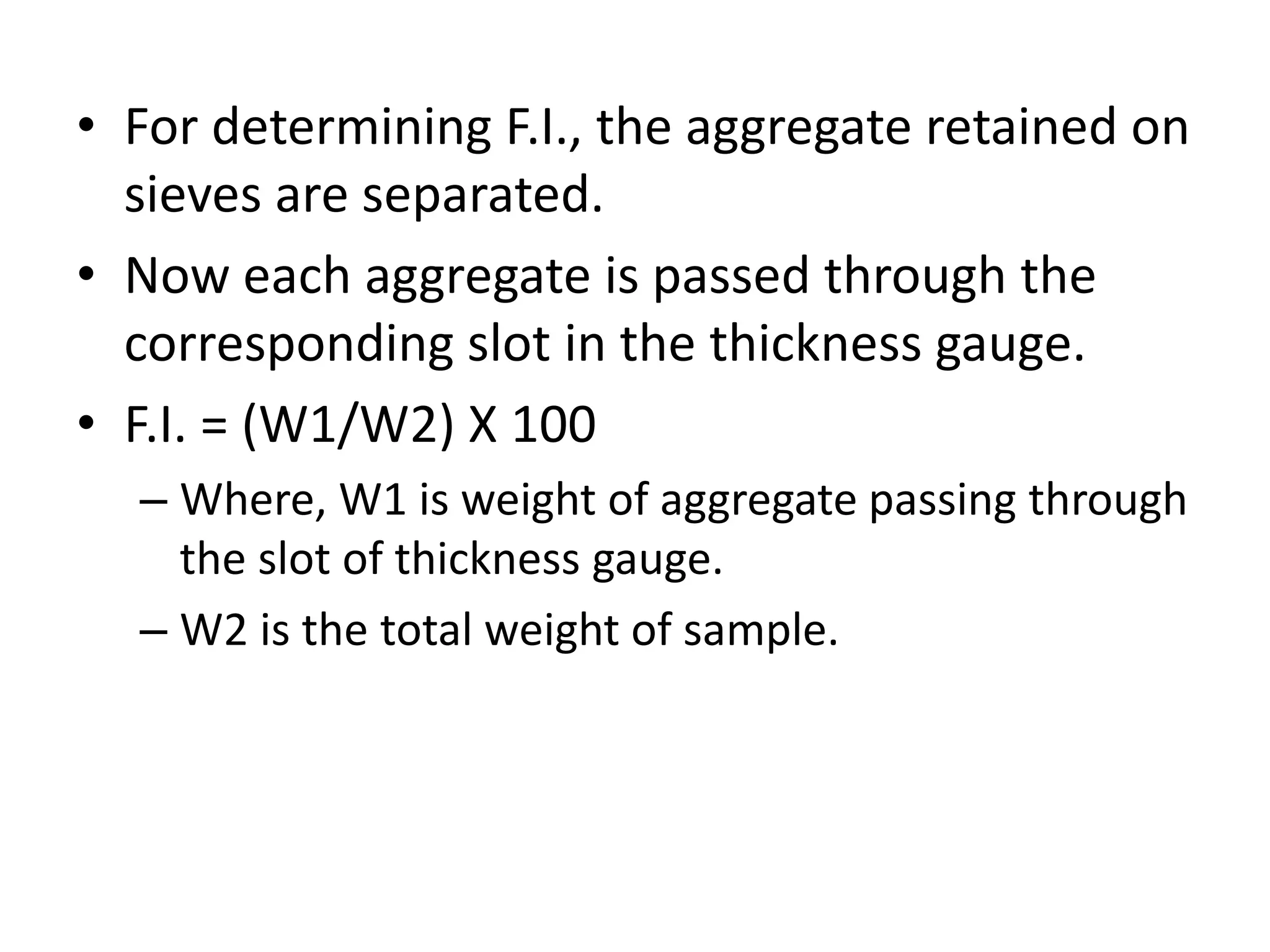

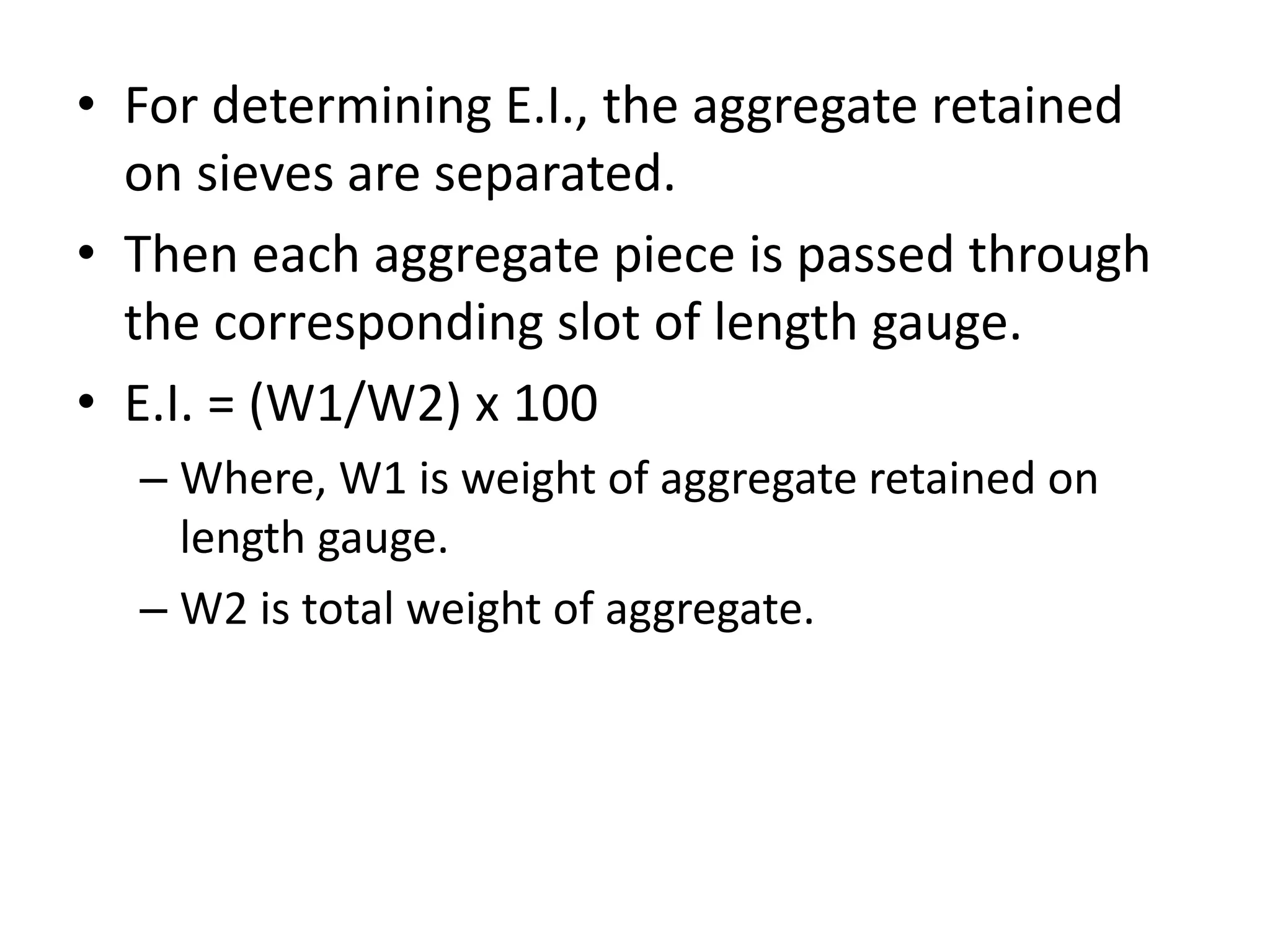

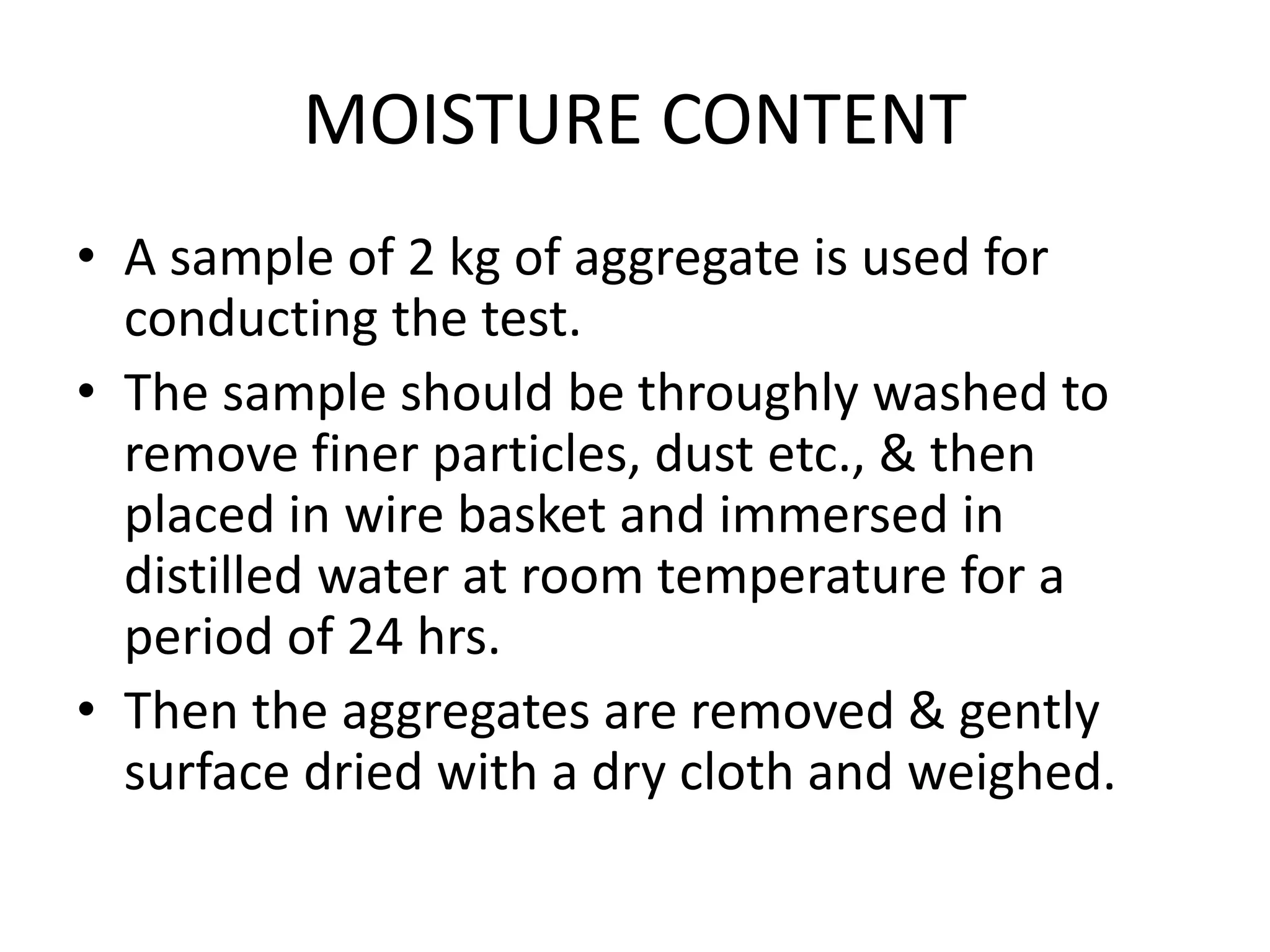

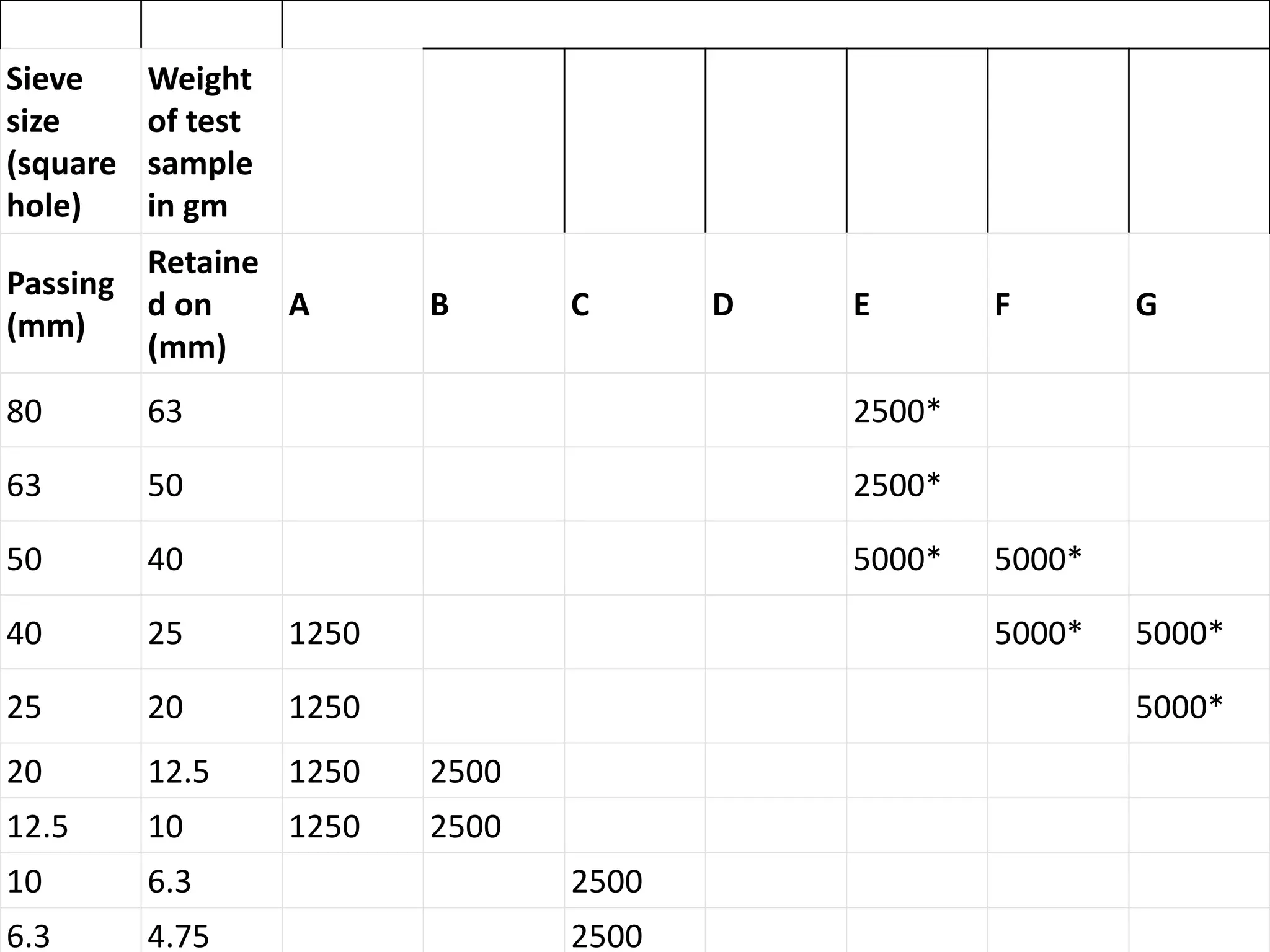

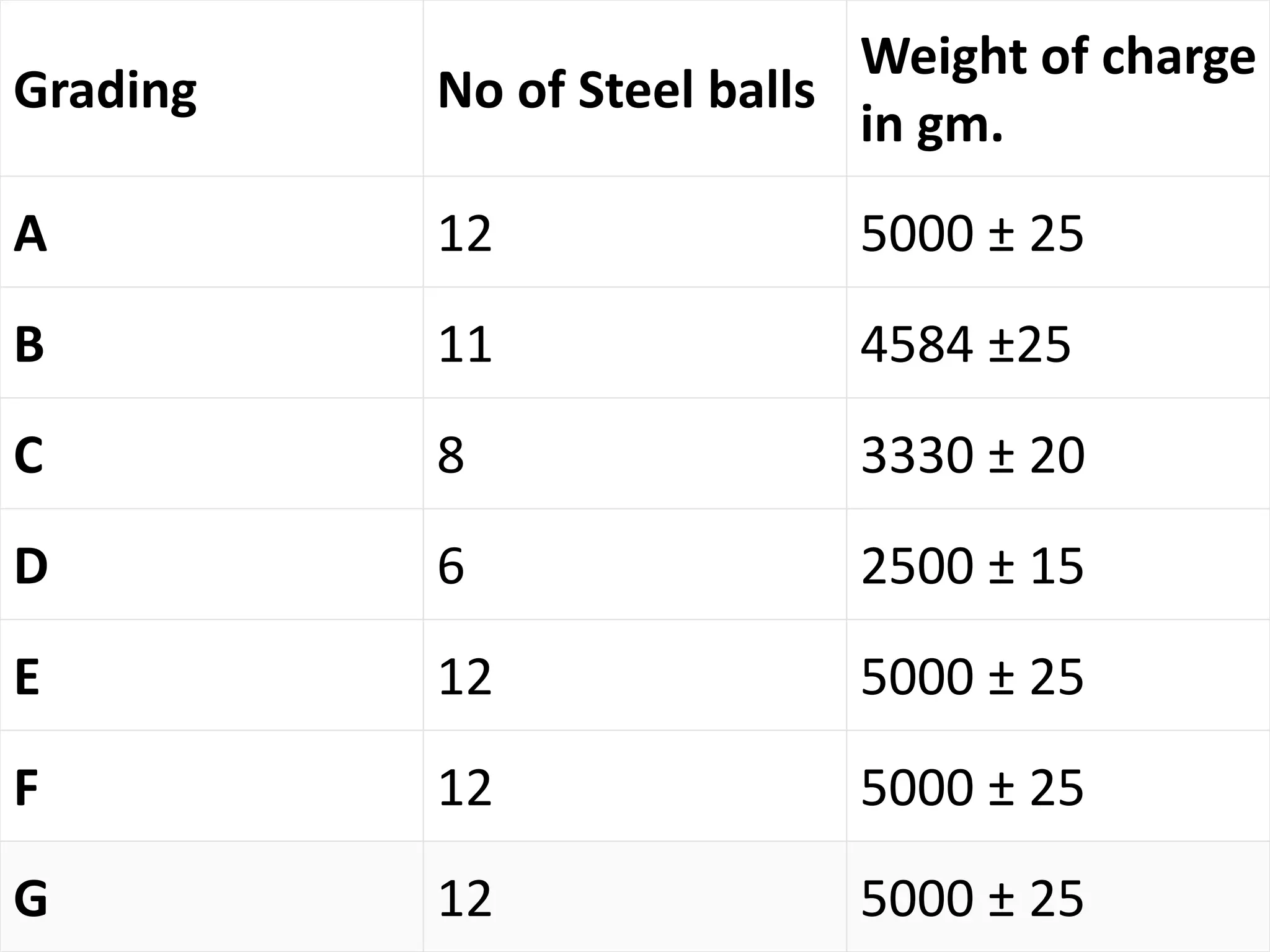

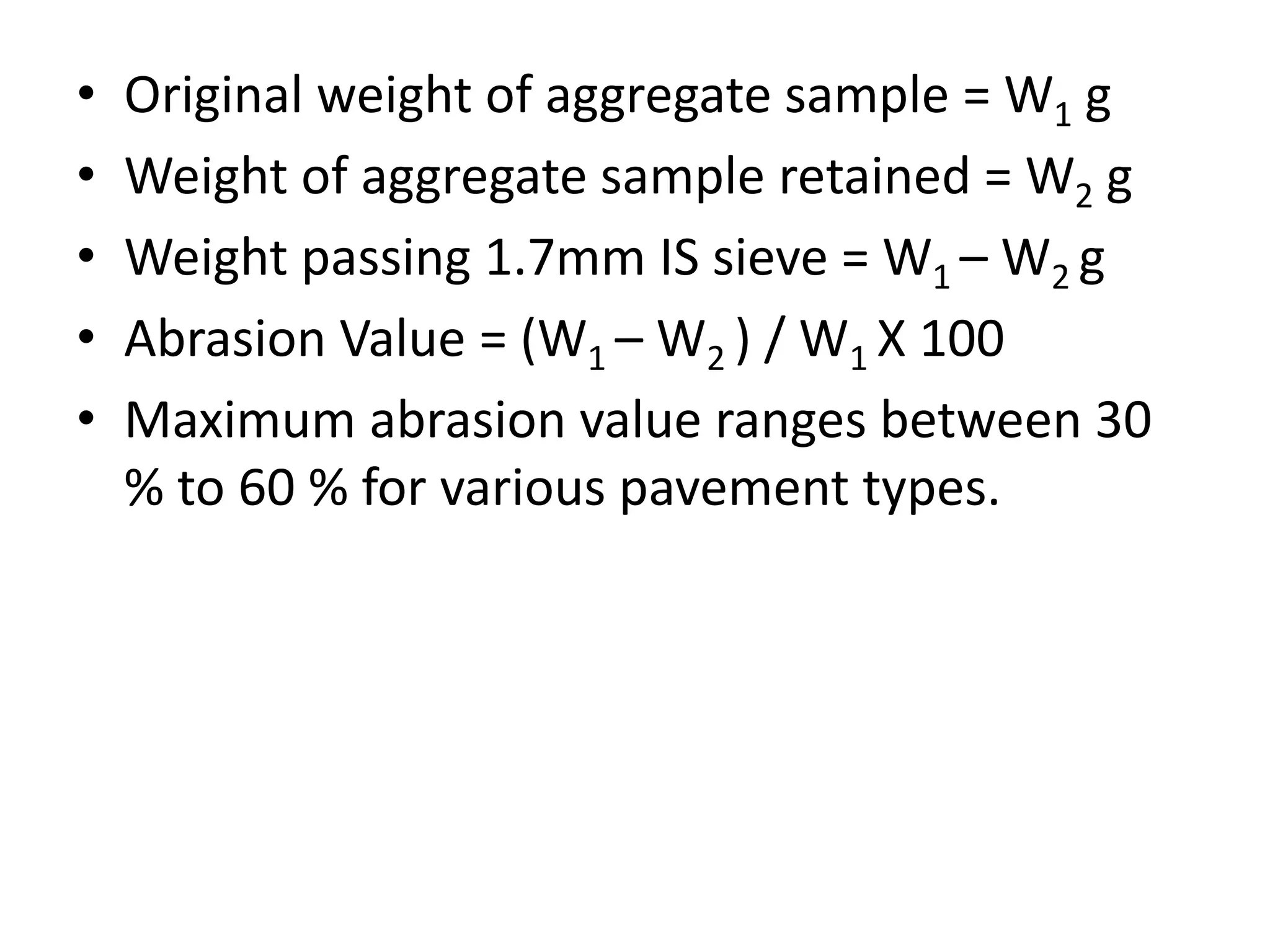

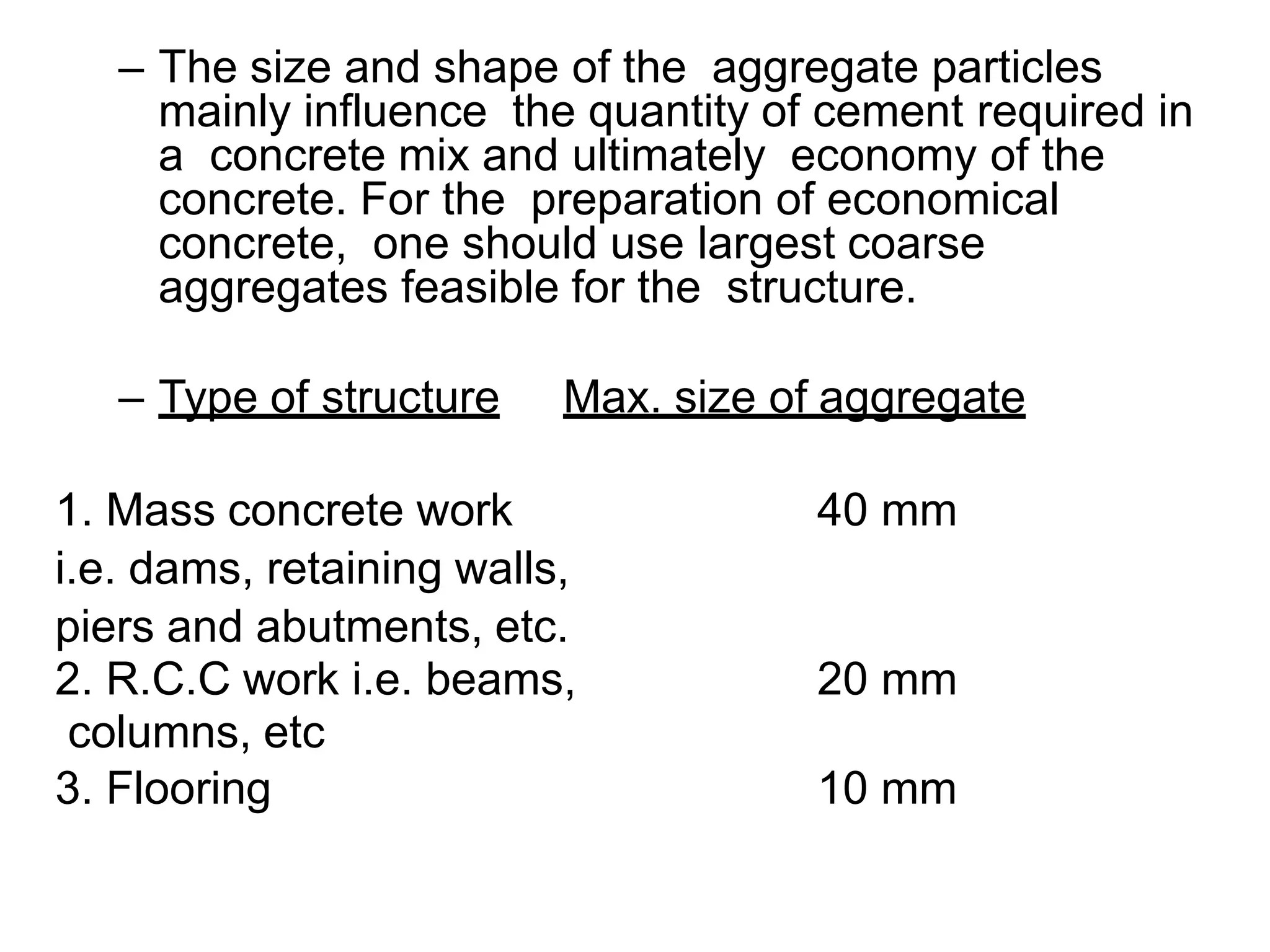

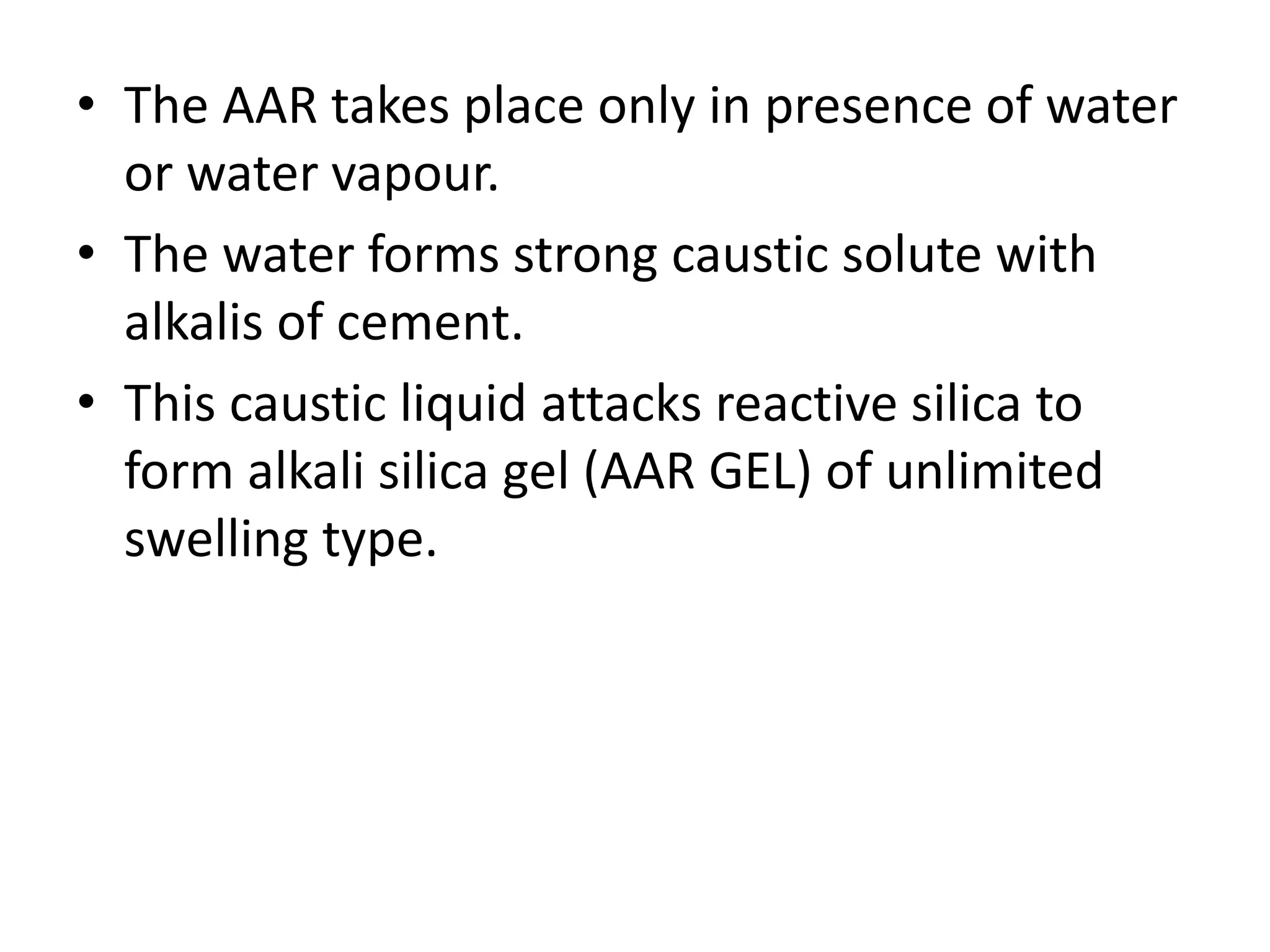

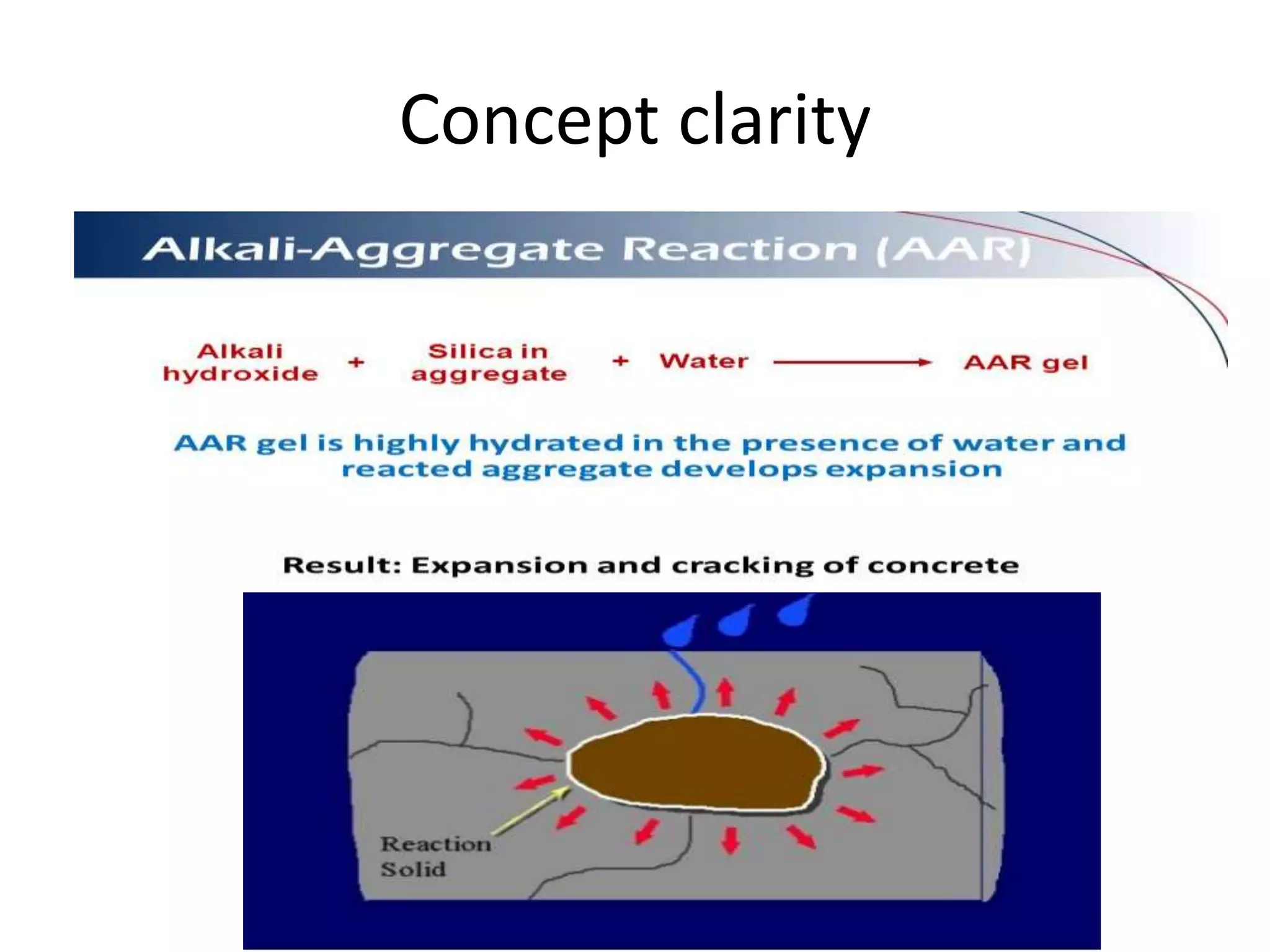

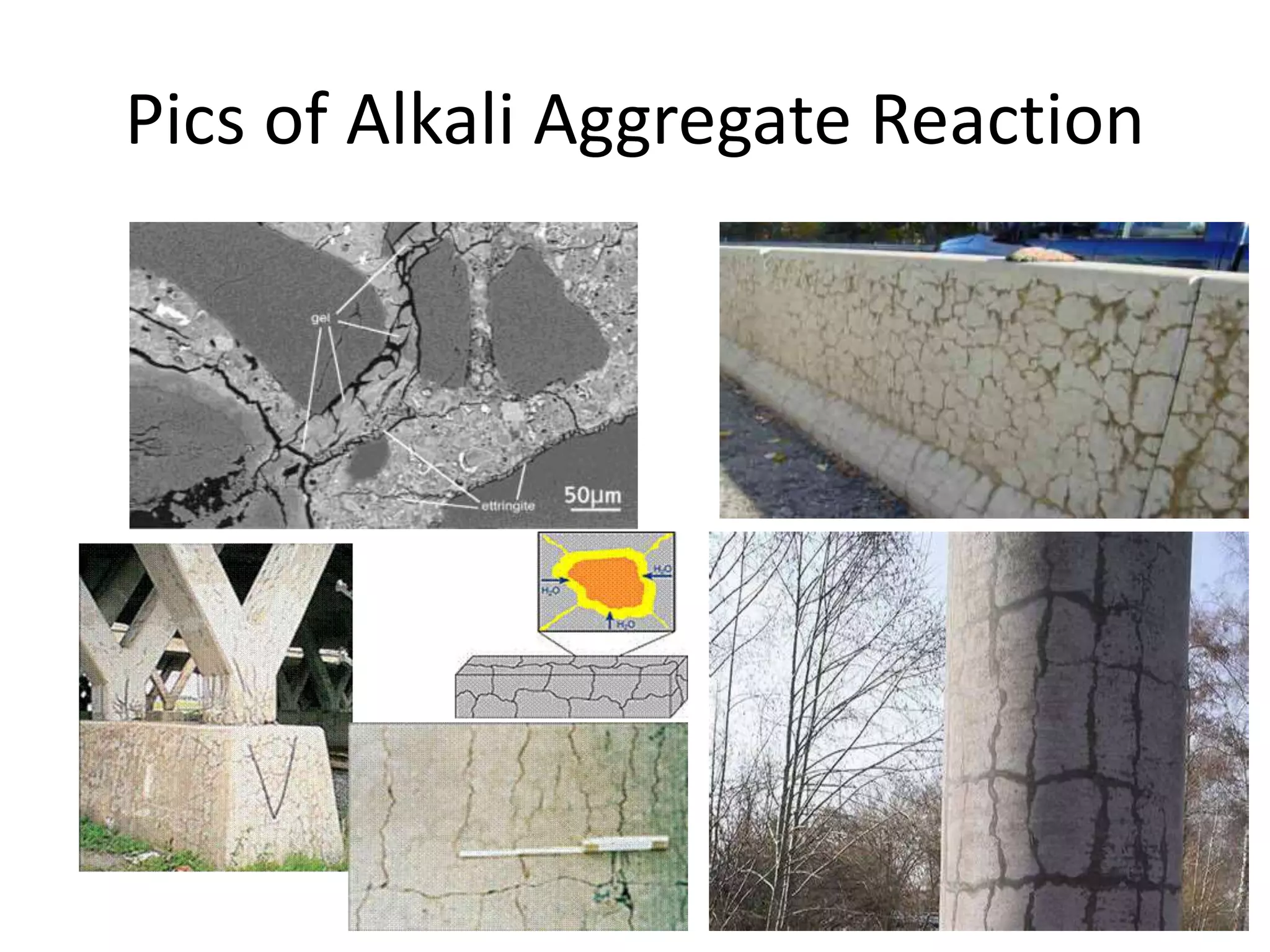

This document provides information on aggregates used in traditional building materials. It defines aggregates as fillers used with binding materials that are derived from rocks. Aggregates make up 70-80% of concrete's volume and influence its properties. Aggregates are broadly classified into fine aggregates smaller than 4.75mm and coarse aggregates larger than 4.75mm. The document discusses various types of coarse aggregates based on geological origin, size, shape, and unit weight. It also covers properties of aggregates like strength, shape, specific gravity, moisture content and tests conducted on aggregates. Alkali aggregate reaction and measures to prevent it are summarized.

![Factors affecting Alkali Aggregate

Reaction

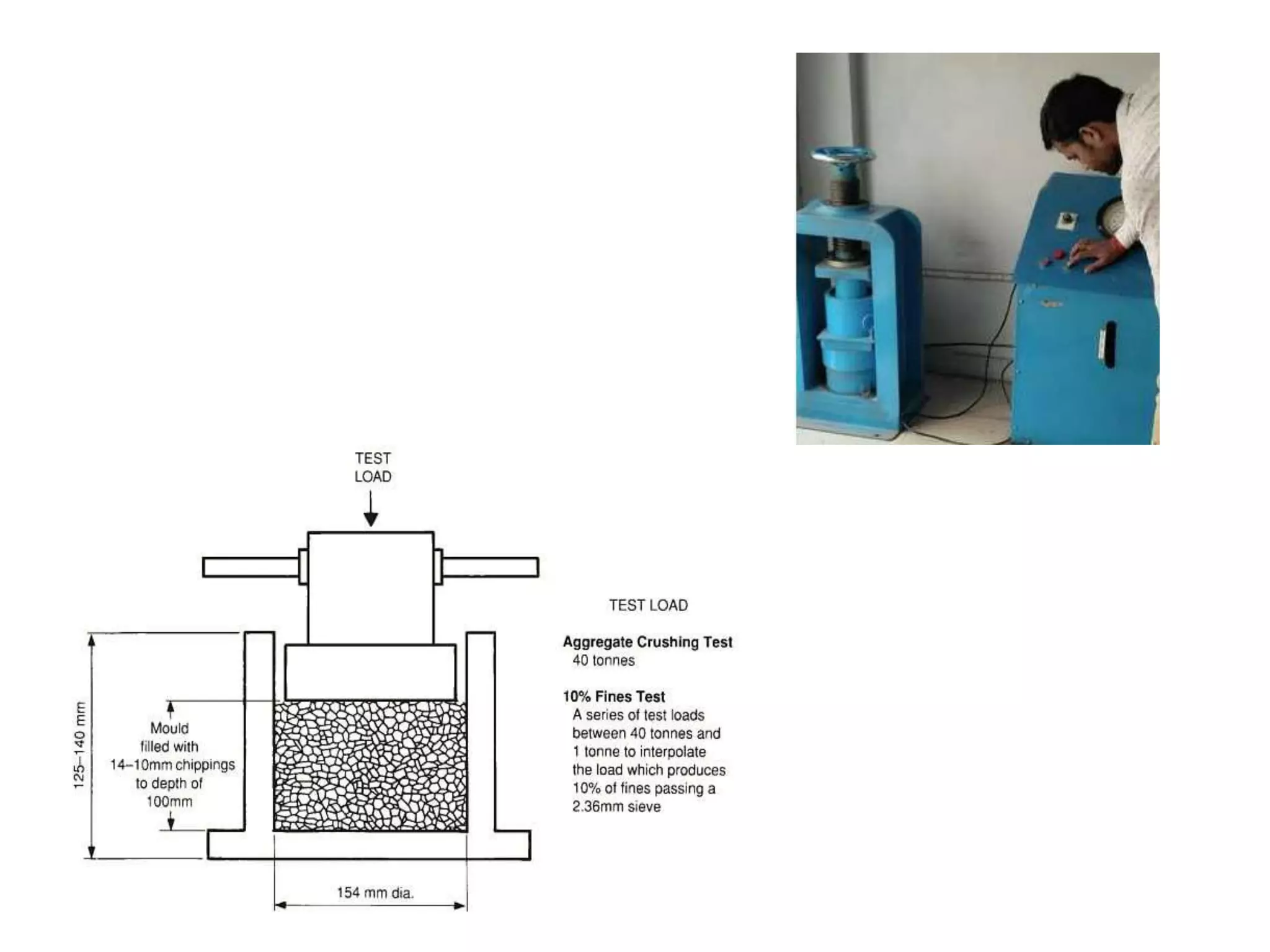

1) Reactive type of aggregates [REACTIVE SILICA], have been

found to have serious effects IF PRESENT IN SMALL

QUANTITIES BUT NOT if it constitutes the whole of

aggregate.

2) High alkali content of cement. If there is very small amount

of alkalis in cement and very reactive silica it is not a

problem, however the increase in alkali content [> 0.6 %] of

cement posses issues of AAR.

3) Availability of Moisture Content. AAR occurs ONLY in the

presence of moisture, which is the reason why AAR is NOT

observed in the interior mass of concrete.

4) Temperature Conditions should be favourable, generally in

the range of 10 to 380C.](https://image.slidesharecdn.com/aggregate-180905115300/75/Aggregate-coarse-aggregates-testing-limits-28-2048.jpg)

![Control of Alkali Aggregate reaction

a) By selecting non – reactive aggregate.

b) By using Low Alkali Cement.

c) By controlling Moisture Content.

d) By using Puzzolonas [REACTIVE SILICA]

– The aggregates are found to be reactive when they

contain silica in a particular proportion and fineness.

When fly-ash or surkhi or dust is added this optimum

condition of silica being in particular proportion and

fineness is disturbed and the aggregates become passive.

e) By adding air-entraining agents.

– Alkali silica gel which imparts pressure over the set

cement gel, can be negated with the addition of air

entraining agents which absorb the osmotic pressure.](https://image.slidesharecdn.com/aggregate-180905115300/75/Aggregate-coarse-aggregates-testing-limits-29-2048.jpg)