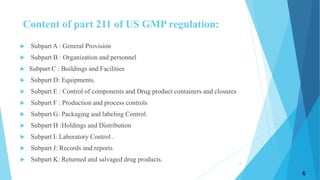

GMP regulations are designed to minimize risks in pharmaceutical production. They provide a framework to assure safety, identity, strength, quality and potency of drug products. GMPs require controlled production and adherence to regulations under the Federal Food, Drug and Cosmetic Act. The US GMP regulations are divided into parts 210 and 211, addressing building and facilities, equipment, packaging, labeling, holding, returns, and more. GMPs help ensure drug products are manufactured and controlled using quality standards appropriate for their intended use and to prevent adulteration.