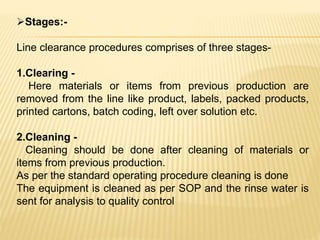

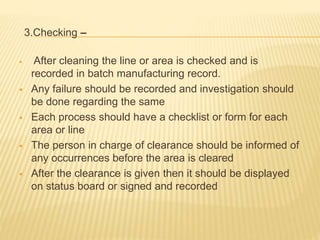

Line clearance is an important procedure to prevent mix-ups and mistakes during manufacturing. It involves three stages: clearing, cleaning, and checking. During clearing, materials from the previous production are removed. Next, cleaning is done according to standard operating procedures. Finally, the line is checked and any issues are recorded before clearance is given to begin the next production. Line clearance must be performed before various stages of production such as dispensing, filling, packaging, and more. It helps ensure safety and quality in manufacturing.