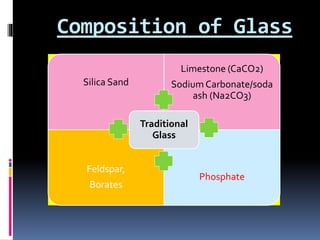

The document provides a comprehensive overview of glass, describing its properties, production processes, and various types, including traditional and special glasses. It highlights technological advancements such as glass windows, lenses, light bulbs, and semiconducting glasses that have influenced society. Additionally, it outlines the methods for processing glass, including float glass and laminated glass, and discusses applications of glass products like solar panels and insulating glass.