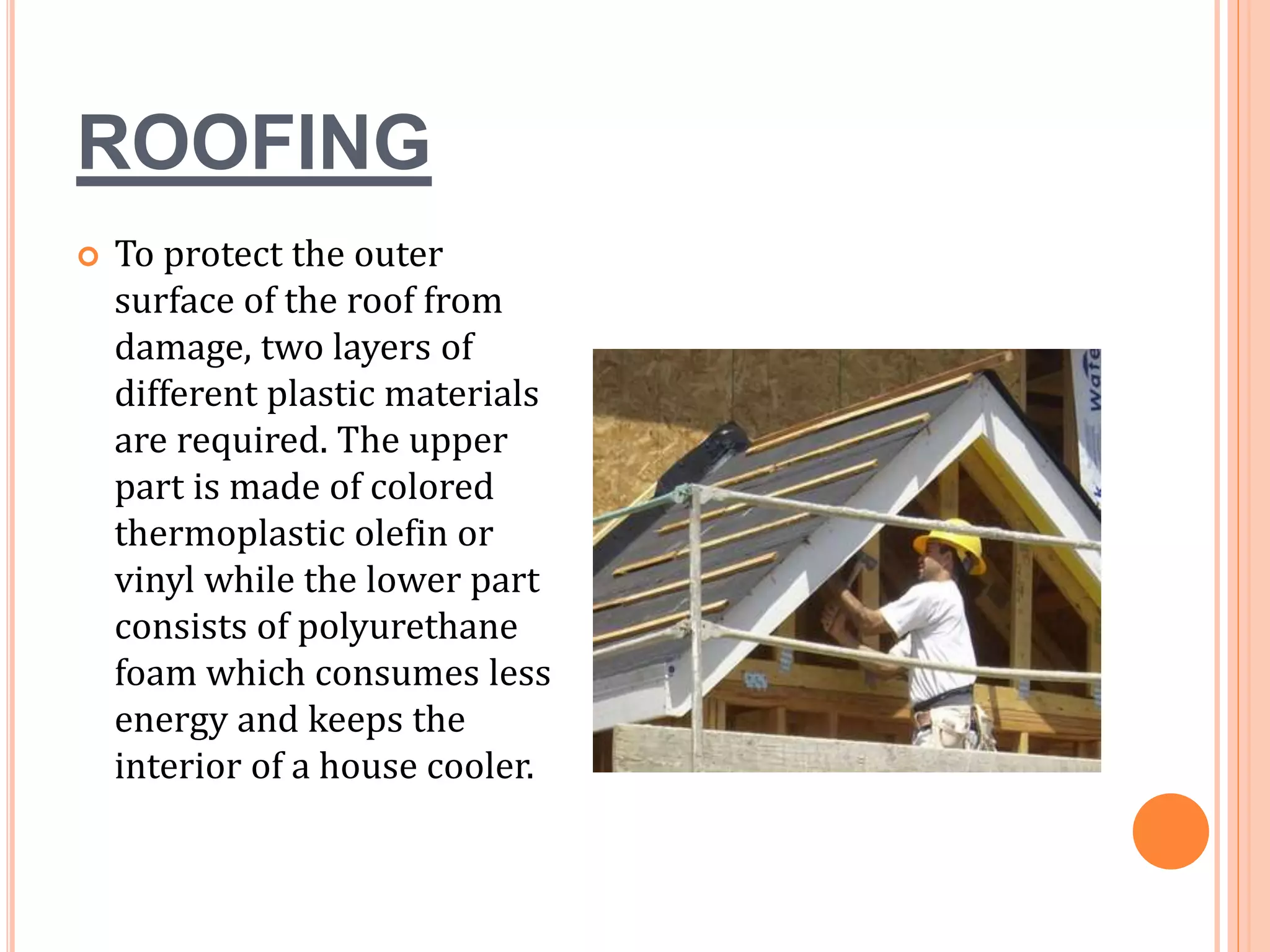

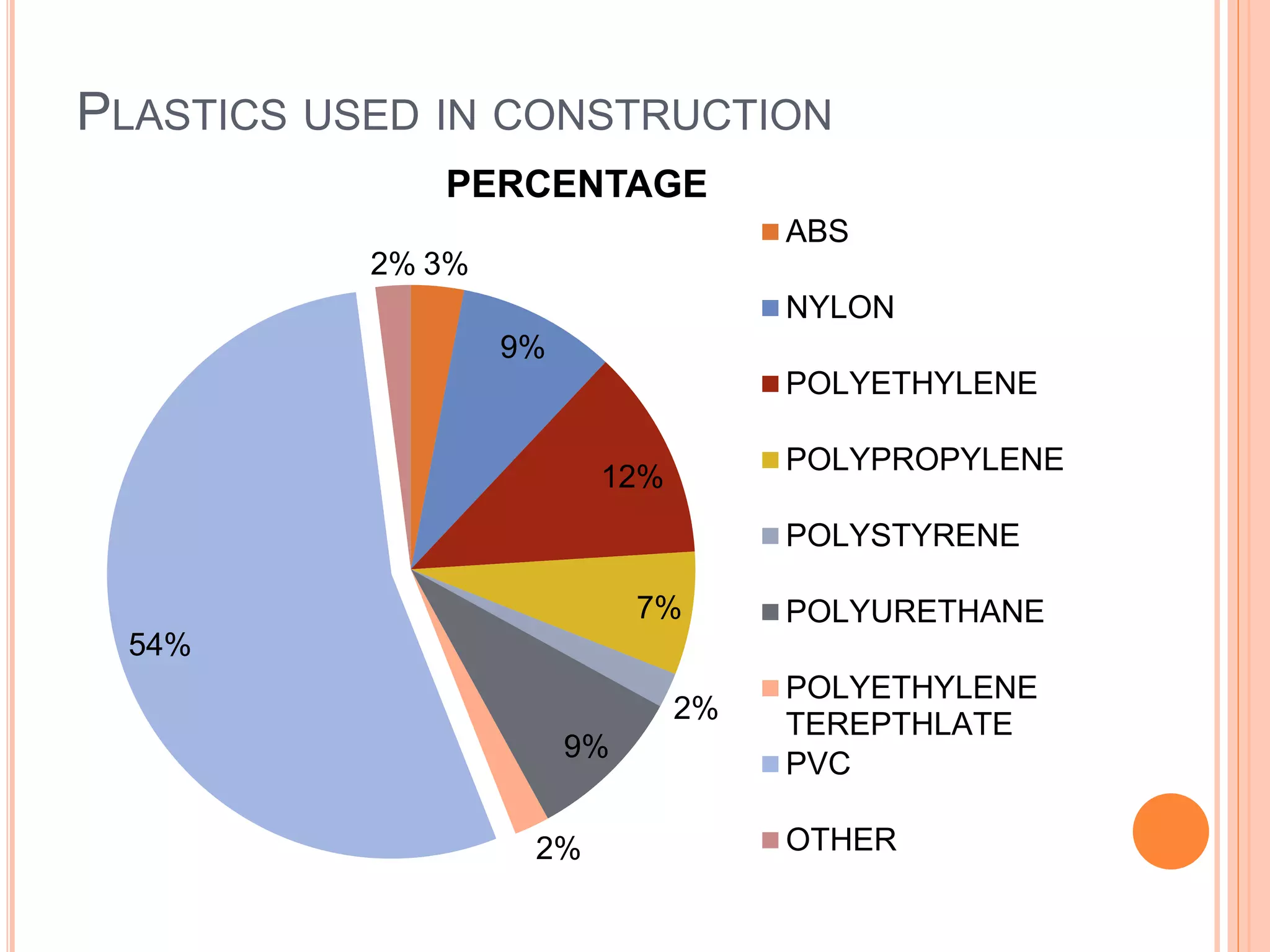

Plastic is a synthetic material made from organic polymers that can be molded while soft and set into a rigid form. It is used widely in the construction industry, including for pipes, cables, flooring, roofing, windows, doors, and more. Some key plastics used are polyvinyl chloride (PVC), polyethylene, polyurethane, and fiberglass. Plastics provide benefits like being lightweight, easy to install, corrosion resistant, and cheap to produce. Methods of making plastic include injection molding, extrusion molding, and blow molding.