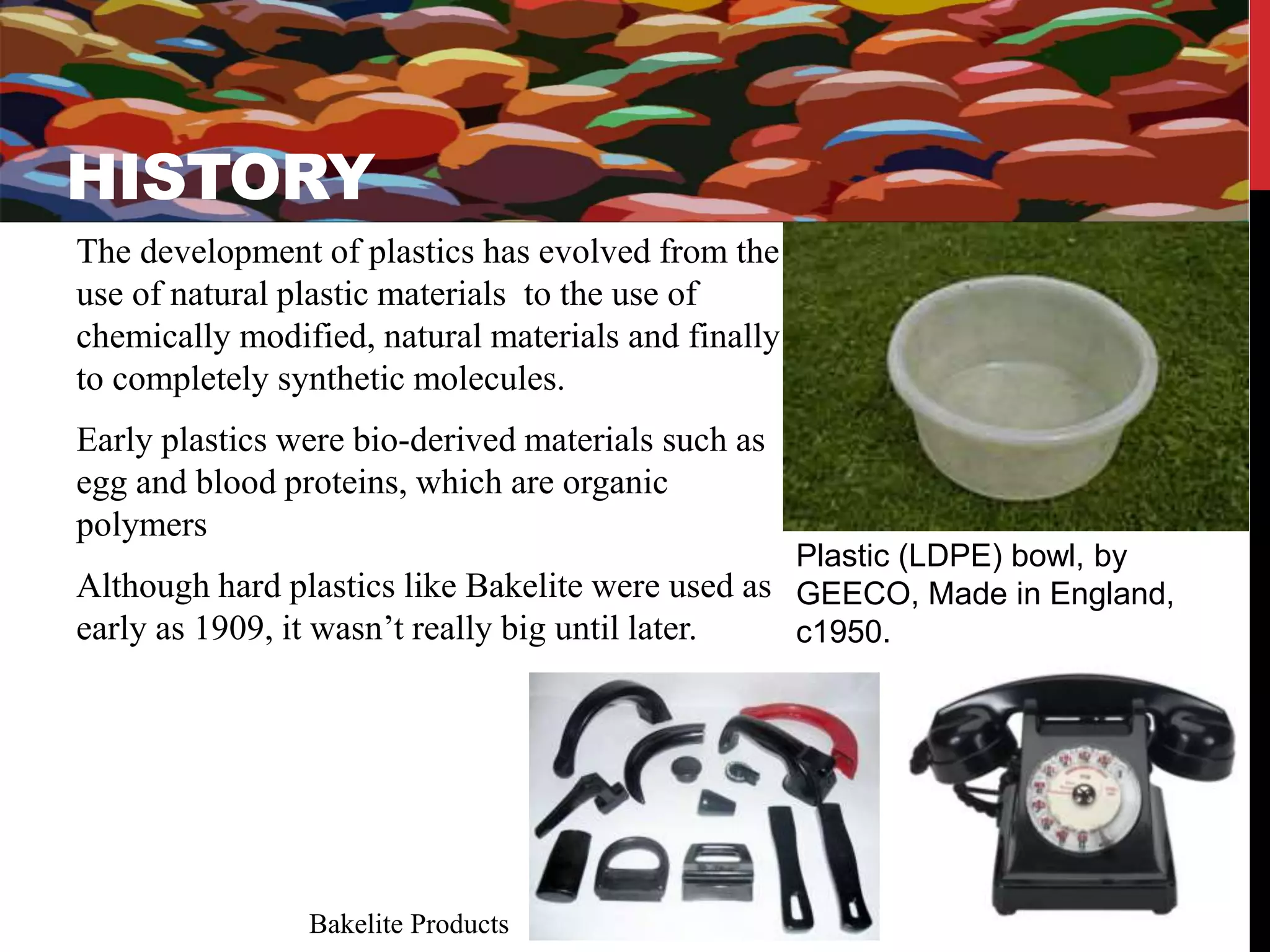

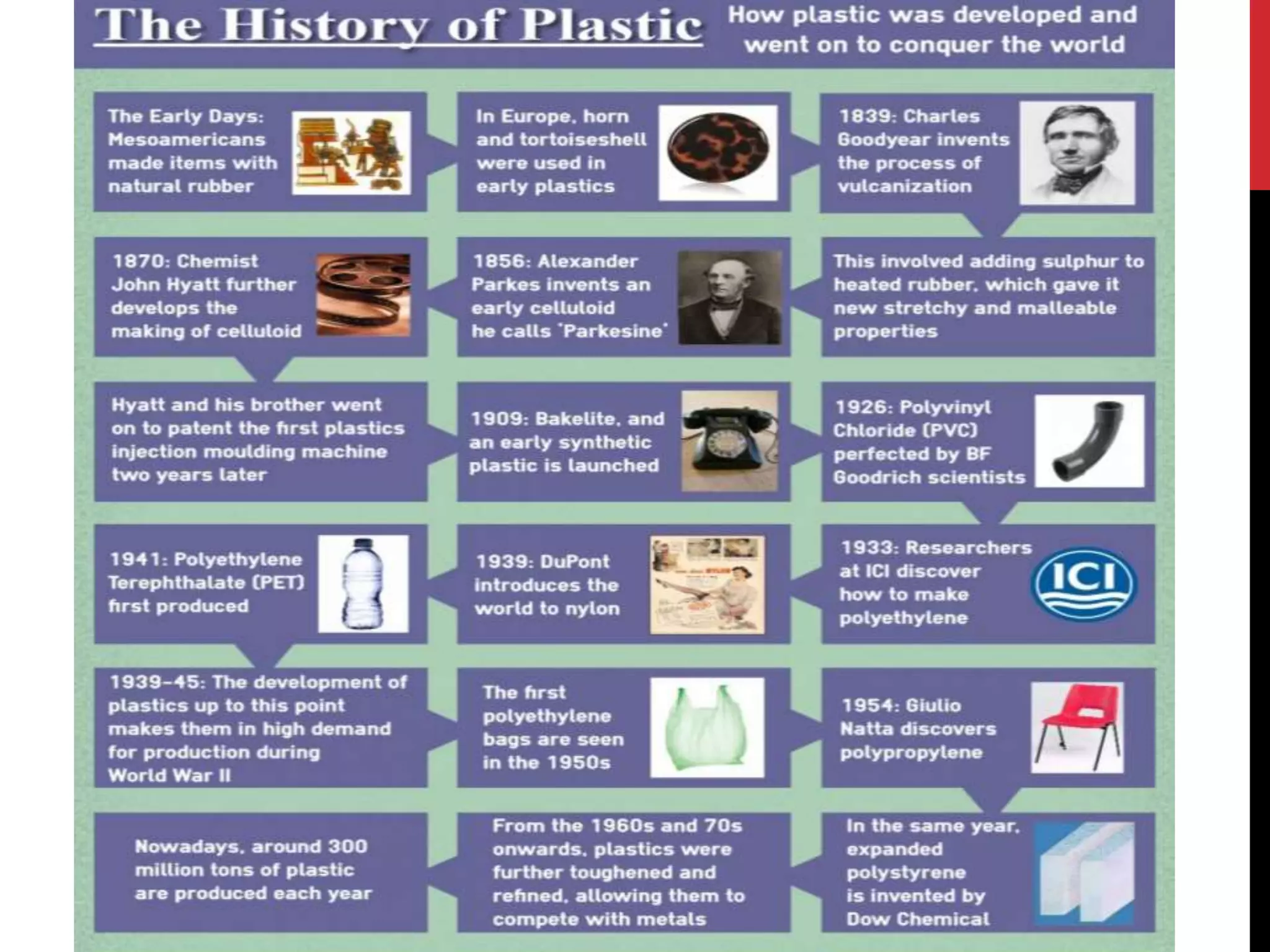

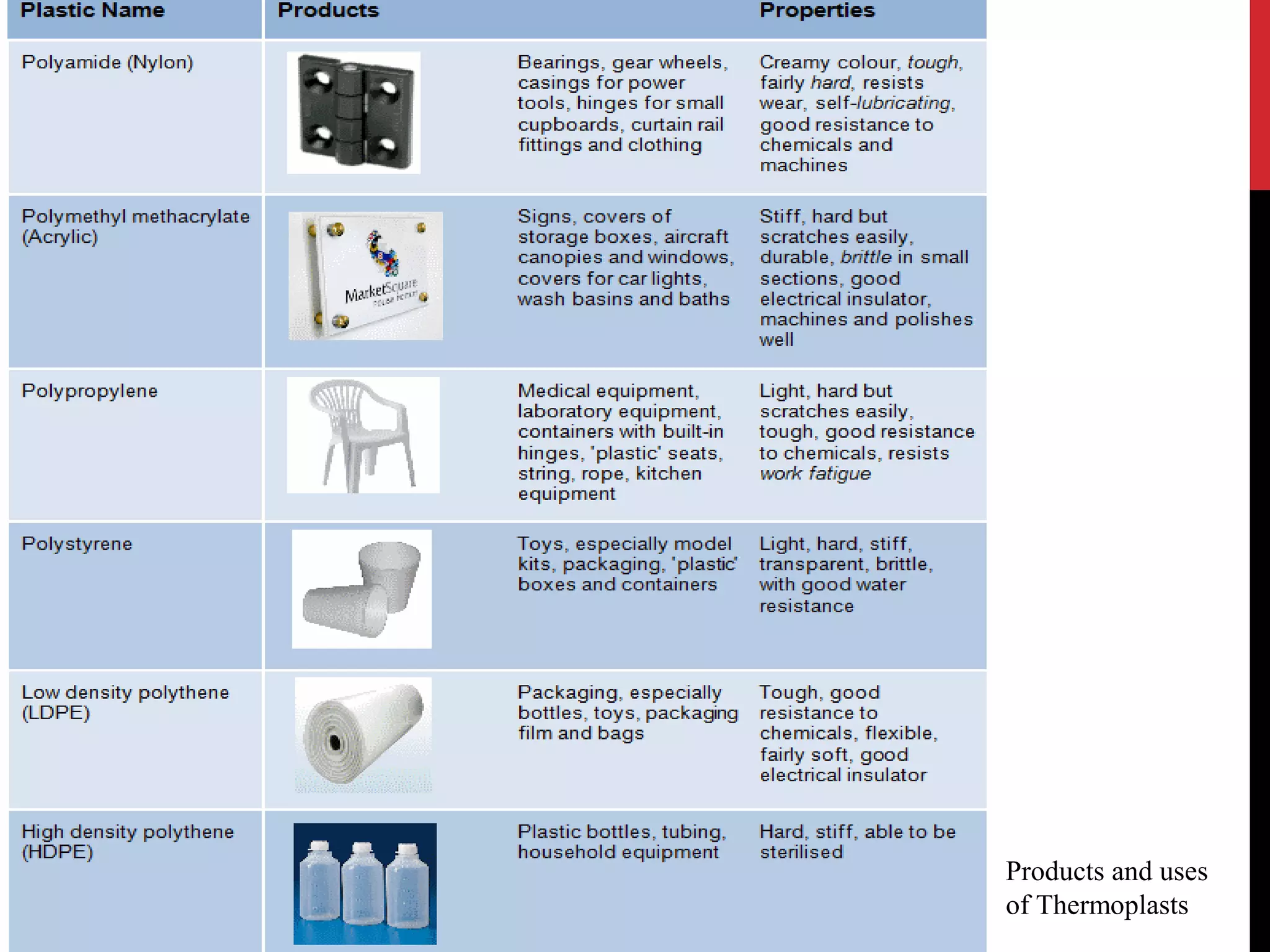

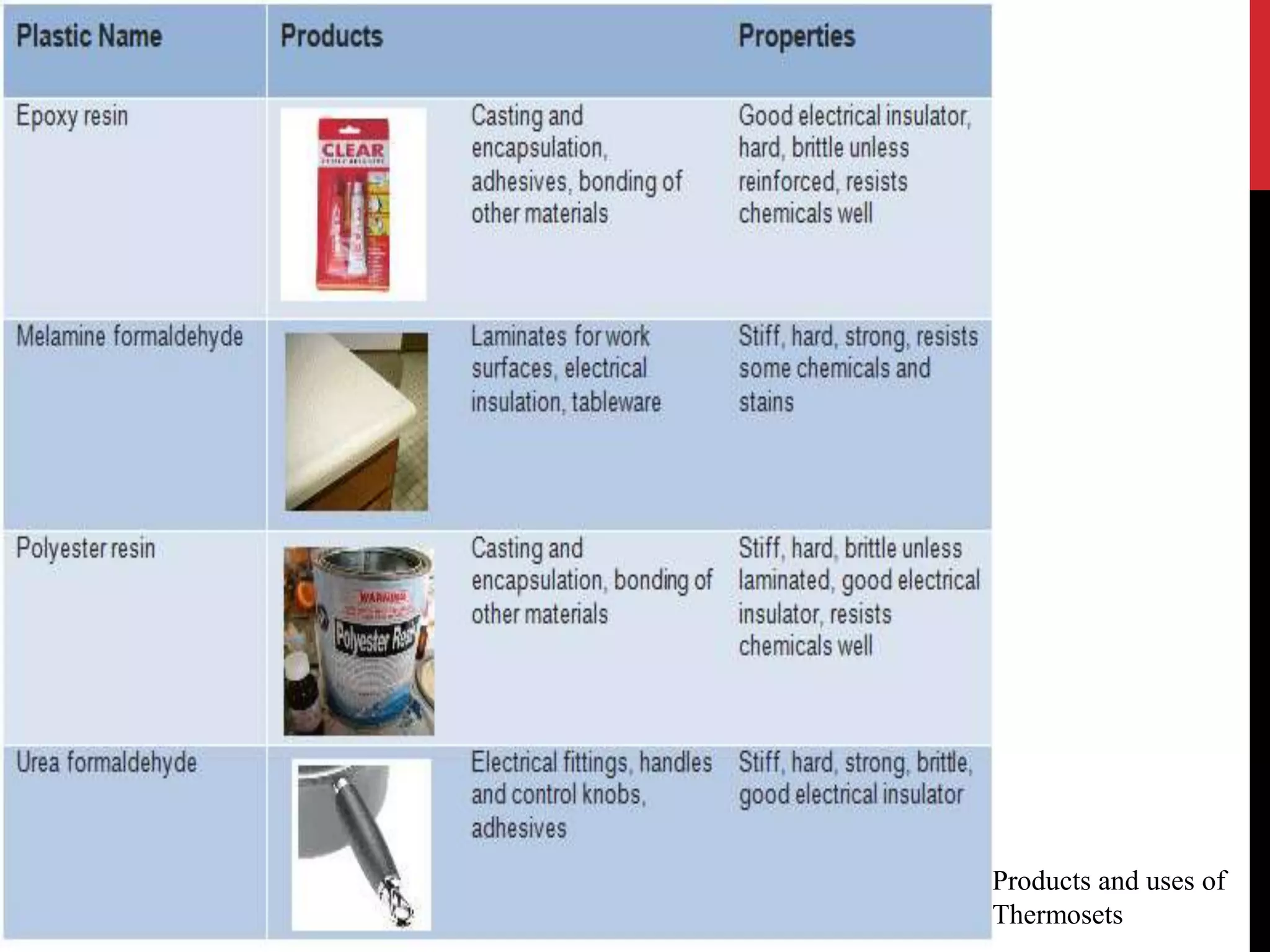

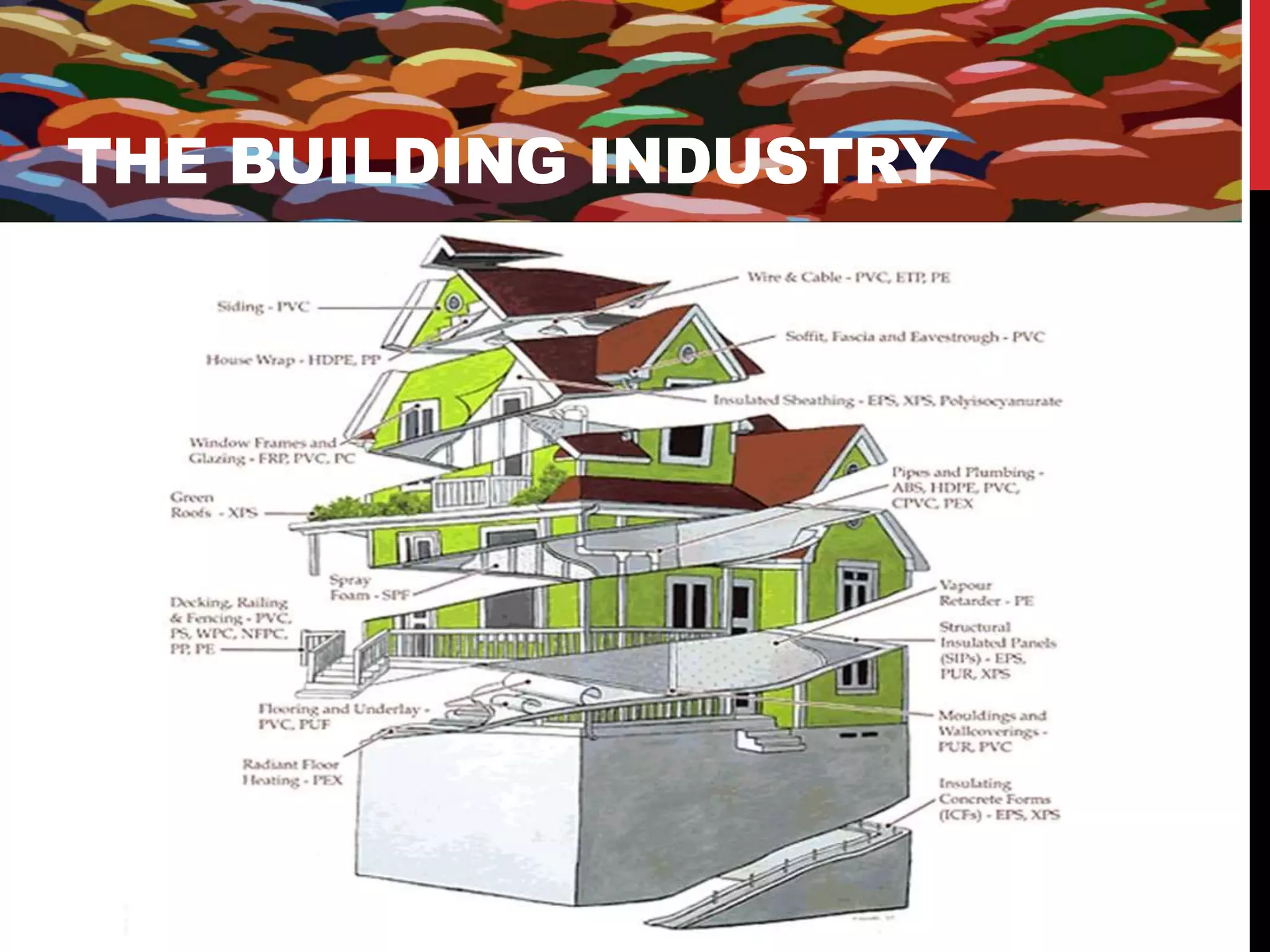

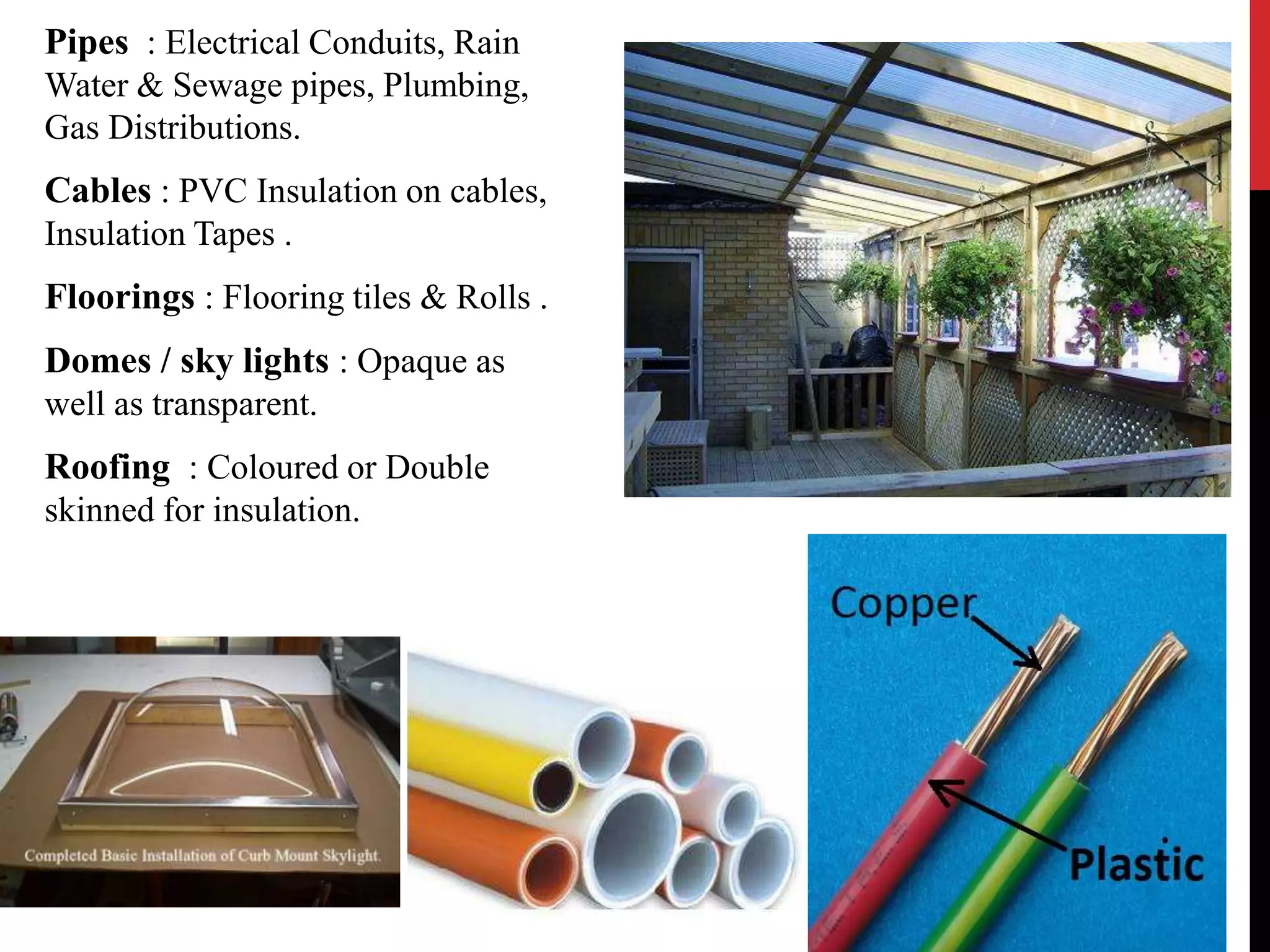

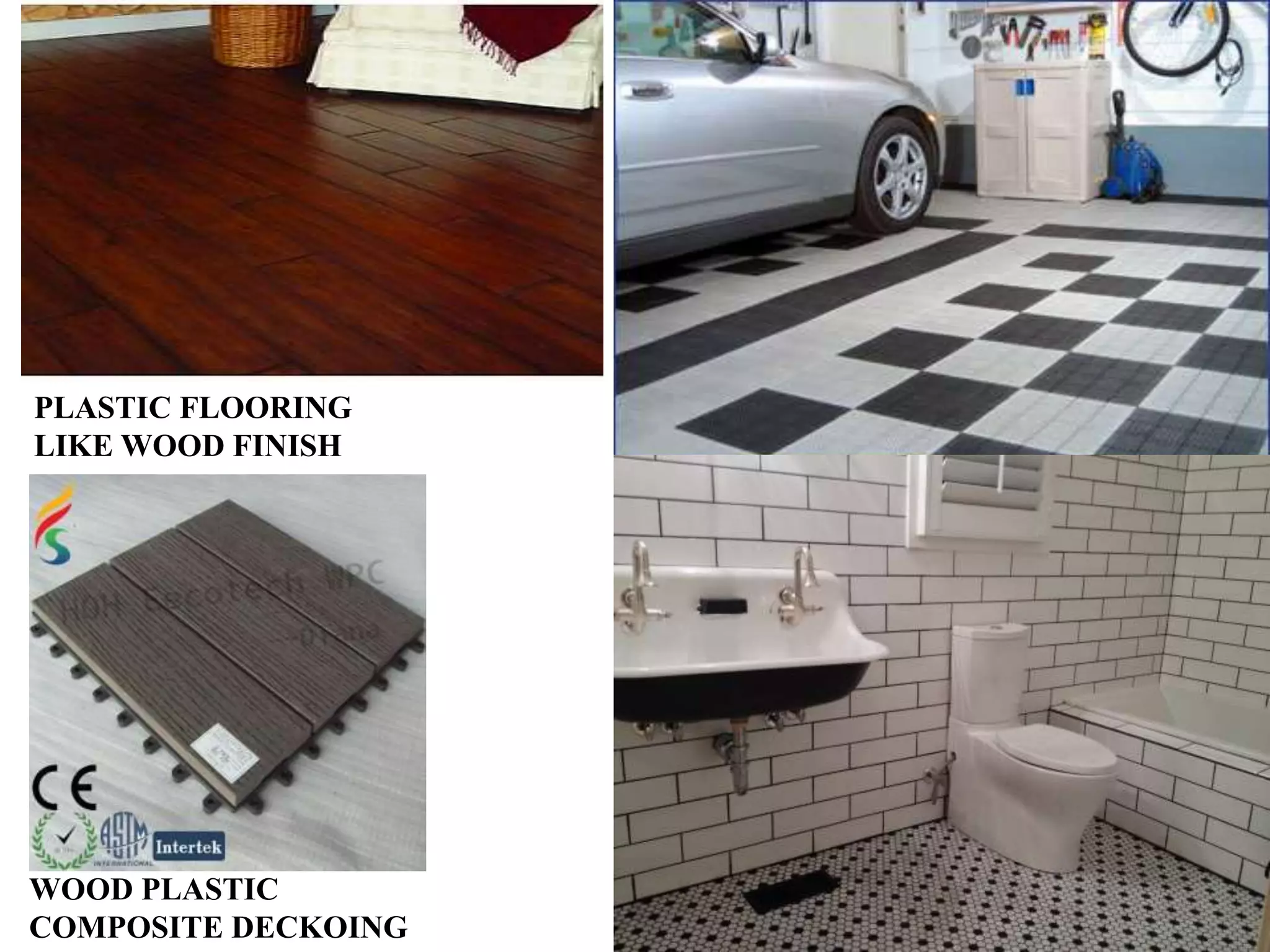

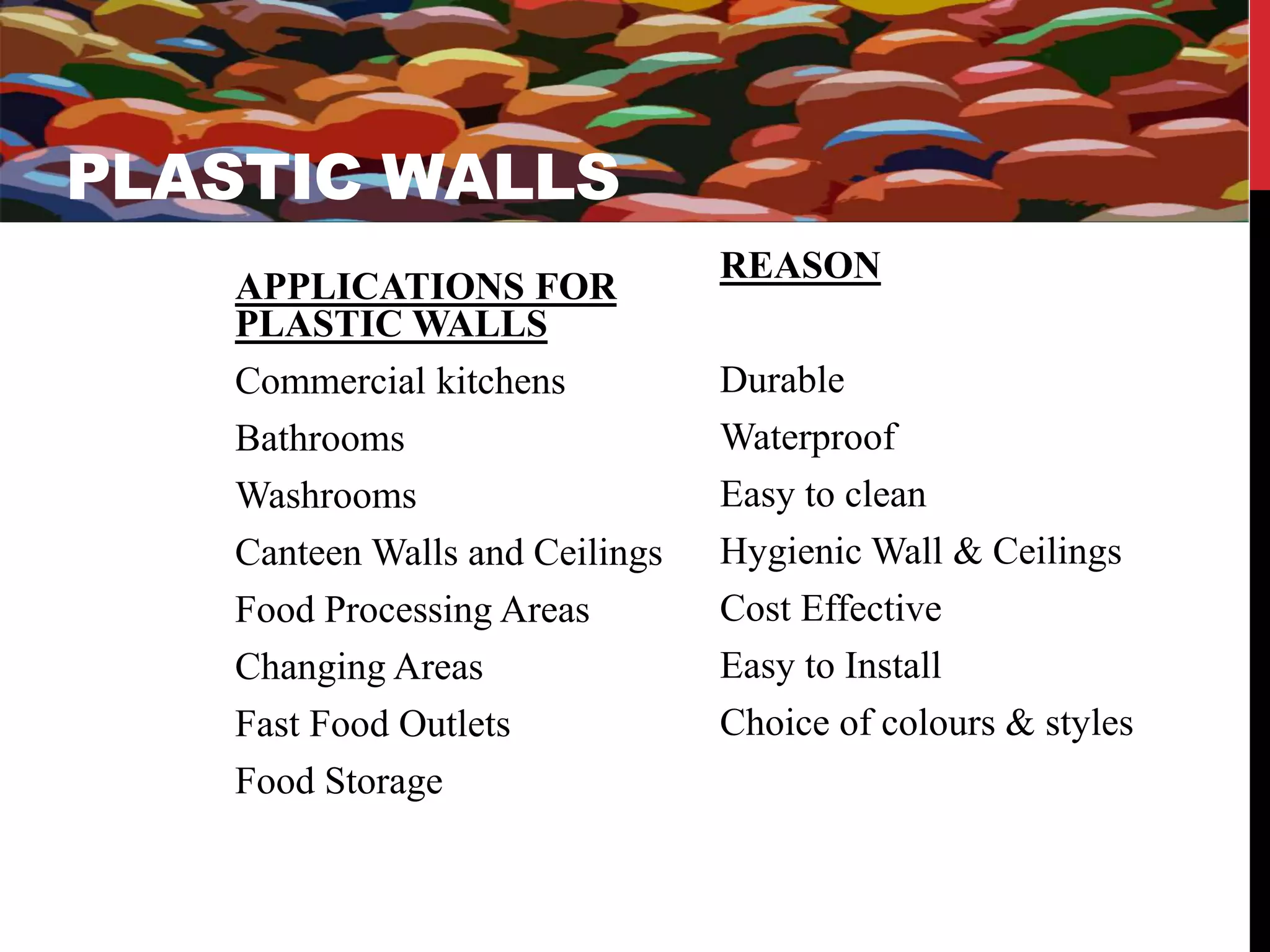

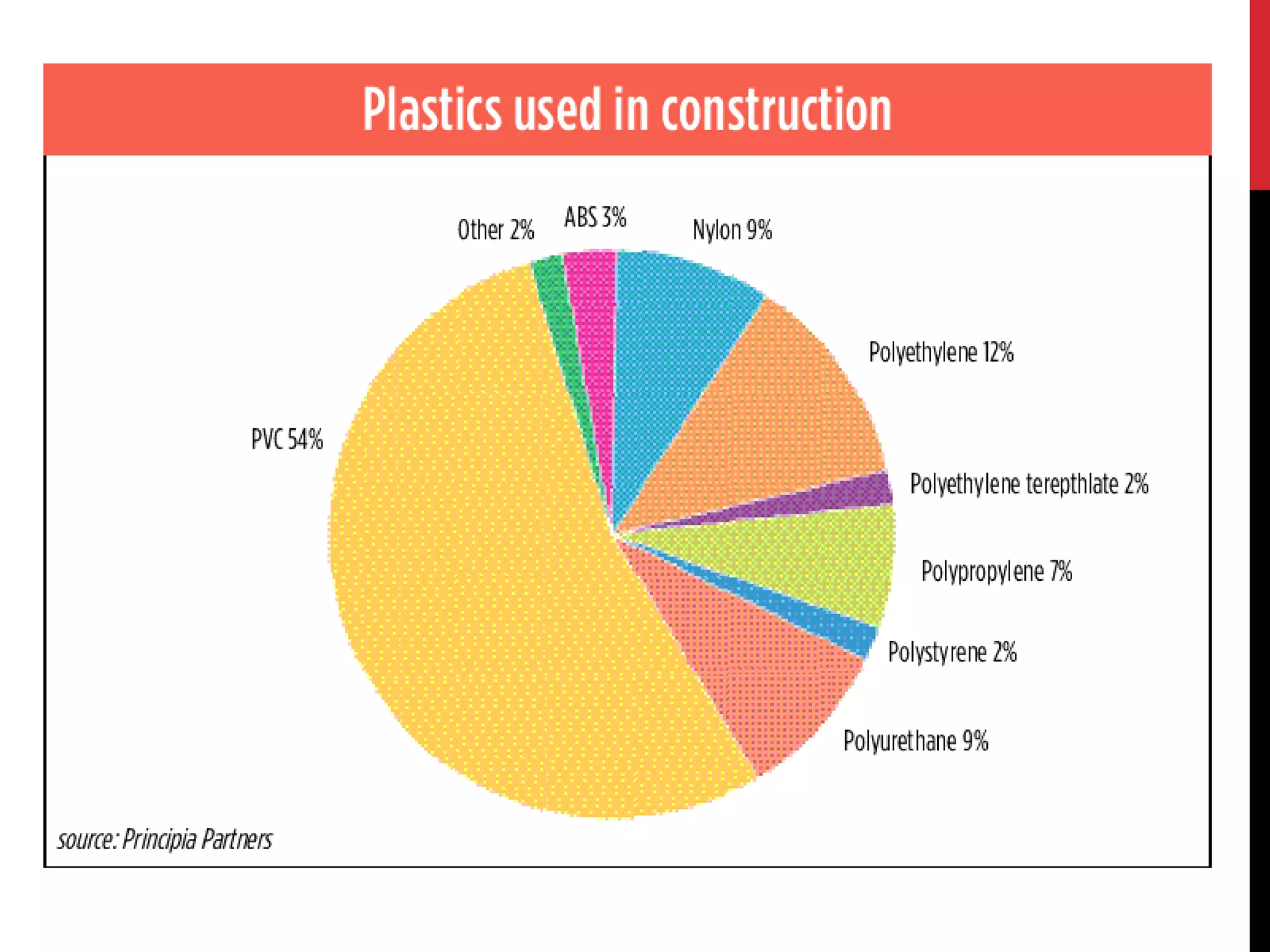

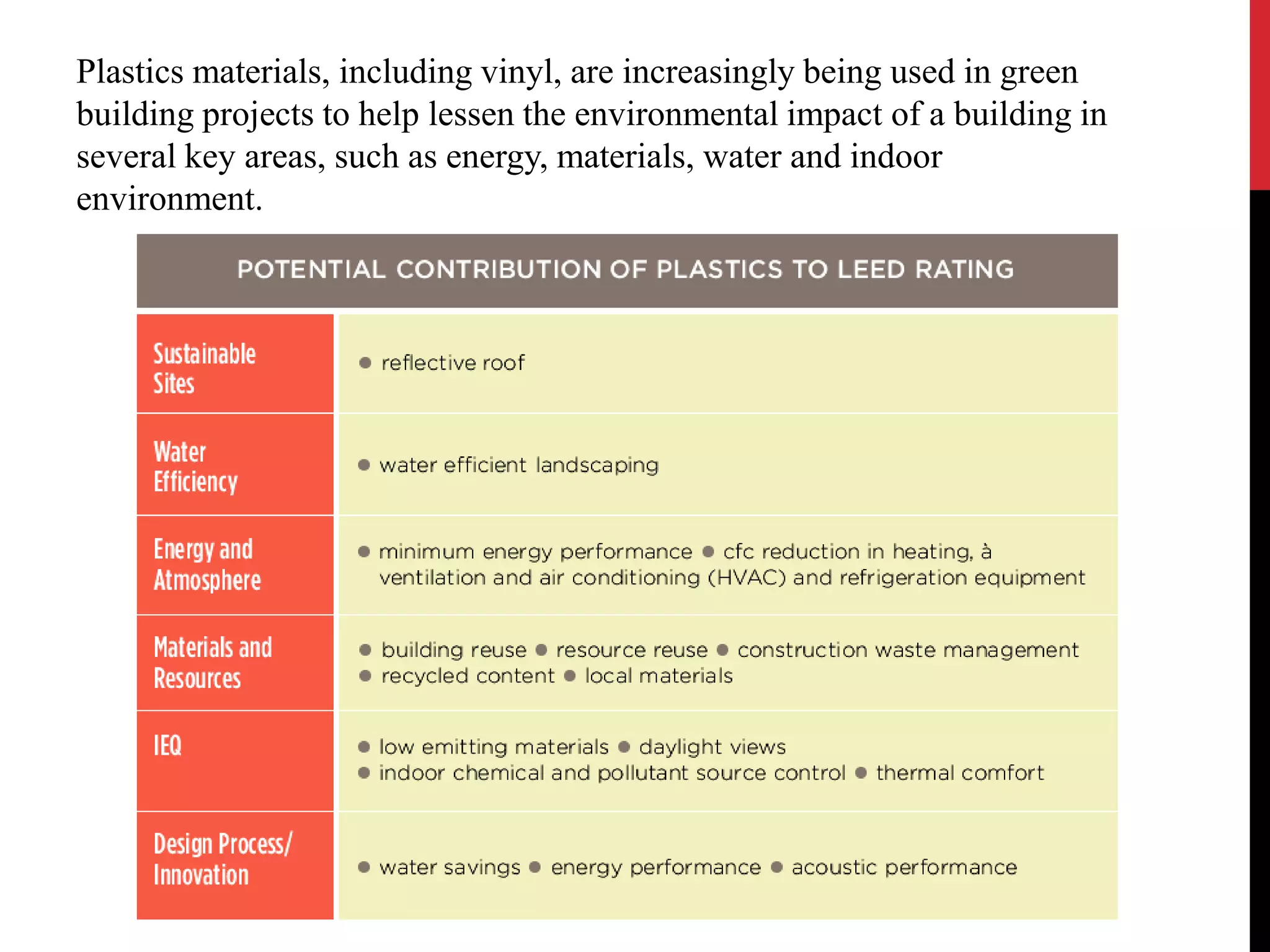

Plastics have become widely used in construction due to their low cost, versatility, and resistance to water. While early plastics were derived from natural sources, completely synthetic plastics later emerged. There are two main types of plastics - thermoplastics that can be reshaped with heat and thermosets that set permanently. Plastics are used in buildings for pipes, cables, flooring, windows, doors, tanks and more. They provide benefits like durability, light weight and resistance to weather, but also have limitations like degradation from sunlight and flammability without treatment.