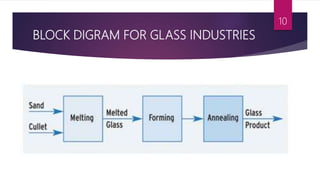

The document discusses the manufacturing process for glass. It begins with an introduction to glass and its properties. It then outlines the raw materials used, including sand, soda ash, calcium oxide and others. The process involves four main steps: melting the raw materials in a furnace at high temperatures; fabricating the molten glass into an article using methods like blowing or casting; annealing the article by slowly cooling it to relieve internal stresses; and applying finishing treatments like bending, cutting or silvering. Key agents in the process include network formers, modifiers and oxidizing agents to control the glass composition and properties.