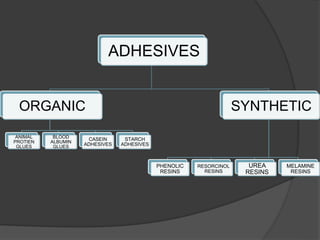

The document discusses different types of adhesives, their properties, uses, and classifications. It describes organic adhesives such as animal protein glues, blood albumin glues, casein adhesives, and starch adhesives. It also discusses synthetic adhesives including phenolic resins, resorcinol resins, urea resins, melamine resins, rubber-based solvent cements, and epoxies. Adhesives are classified as either thermoplastic adhesives or thermosetting adhesives, with thermosetting adhesives generally being more expensive but suitable for structural applications requiring high load resistance.