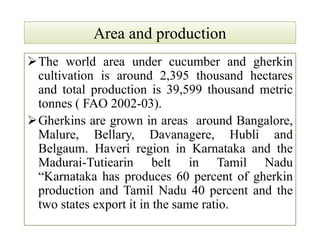

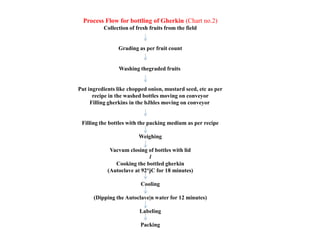

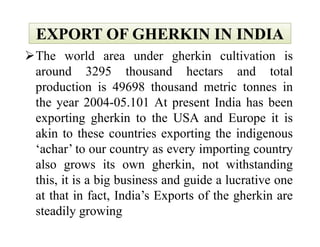

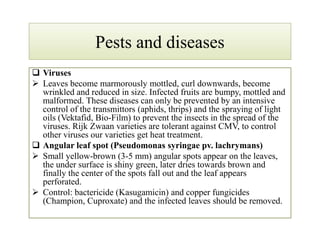

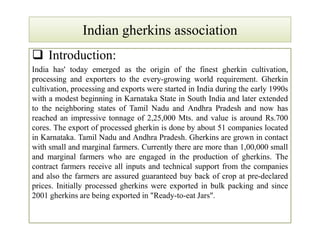

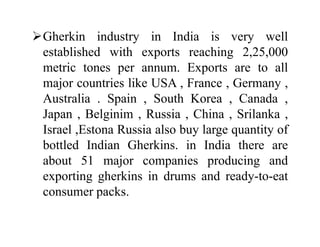

The document provides comprehensive information on gherkin (Cucumis sativus var. angaria) cultivation, including its historical significance, geographical production areas, optimal climate and soil conditions, and detailed agricultural practices. It highlights the importance of gherkins in earning foreign exchange and notes variations in cultivation techniques, such as planting, staking, irrigation, harvesting, and quality control standards. The document emphasizes the need for effective cross-pollination and careful handling of harvested fruits to meet market requirements.