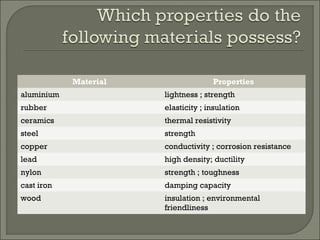

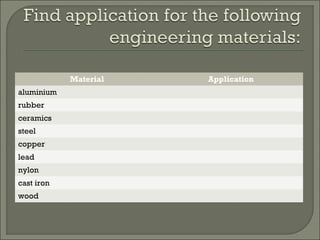

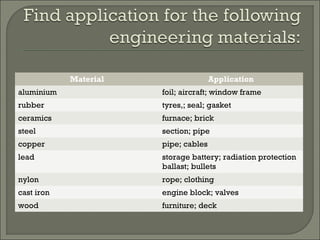

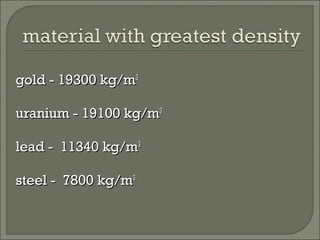

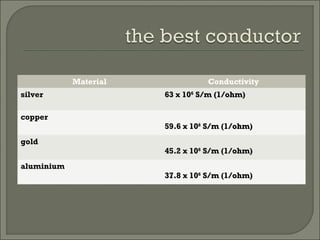

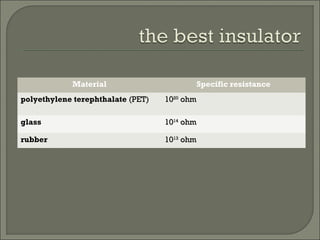

The document discusses various material properties including physical, mechanical, and chemical properties. It provides examples of specific material properties like density, thermal conductivity, tensile strength, and electrical conductivity. It also lists common materials like aluminum, steel, copper, wood and describes some of their key properties and applications. Overall, the document serves as a reference for different material properties and how they relate to material selection and applications.