1) The lecture covered various topics related to machine design including material properties, ferrous materials, heat treatment of steels, fits and tolerances, and interchangeability.

2) Key mechanical properties of metals discussed included elasticity, plasticity, ductility, brittleness, and malleability.

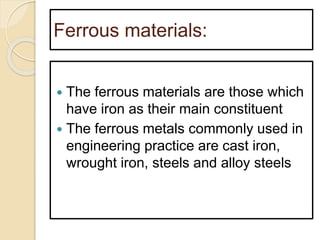

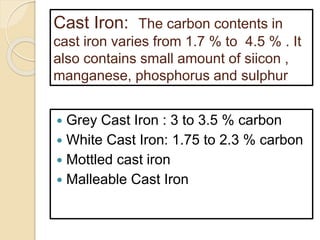

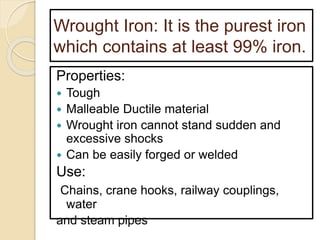

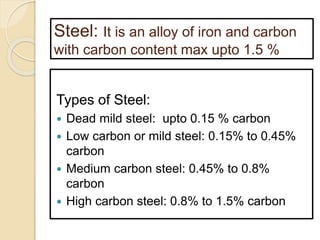

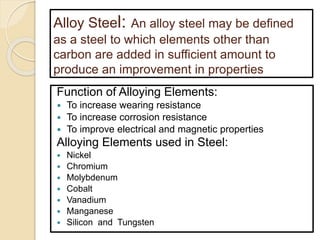

3) The main ferrous materials covered were cast iron, wrought iron, steels, and alloy steels.

4) Heat treatment processes were explained along with their objectives of modifying material properties.