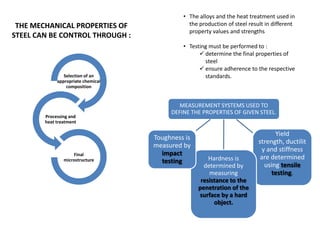

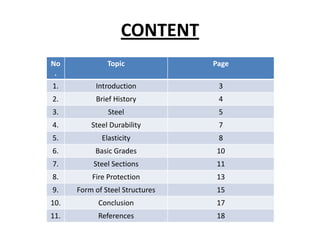

1. This document discusses structural theories and applications of steel as a material. It provides an overview of the physical and mechanical properties of steel, how steel is produced, basic grades of steel, common steel sections, fire protection methods for steel structures, and the form of steel structures.

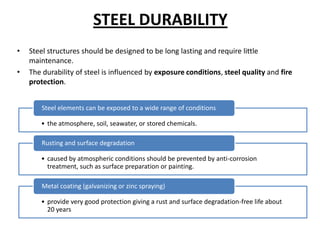

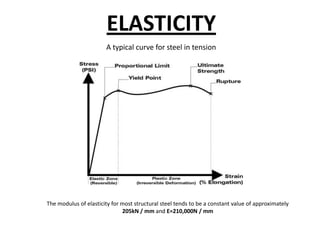

2. The document includes sections on the brief history of steel production, how steel durability is influenced by exposure conditions and treatment, elasticity properties of steel, measurement systems used to define steel properties, and concludes with advantages and disadvantages of steel structures.

3. References are provided and the document contains tables of contents and figures to illustrate steel properties and structural concepts.

![Produced from iron ore

by removing the ore’s

naturally occurring

density ρ = 7.7 ÷ 8.1 [kg/dm3] impurities

elastic modulus E=190÷210

[GPa]

Poisson’s ratio ν = 0.27 ÷ 0.30

High strength in

Thermal conductivity κ = 11.2 tension and

÷ 48.3 [W/mK] compression

Thermal expansion α = 9 ÷27

[10-6 / K]

STEEL

Physical properties of

Able to undergo large

steel are related to

deformation without

the physics of the

fracture

material

Ductile material](https://image.slidesharecdn.com/steel-material-130331213217-phpapp01/85/Steel-material-5-320.jpg)