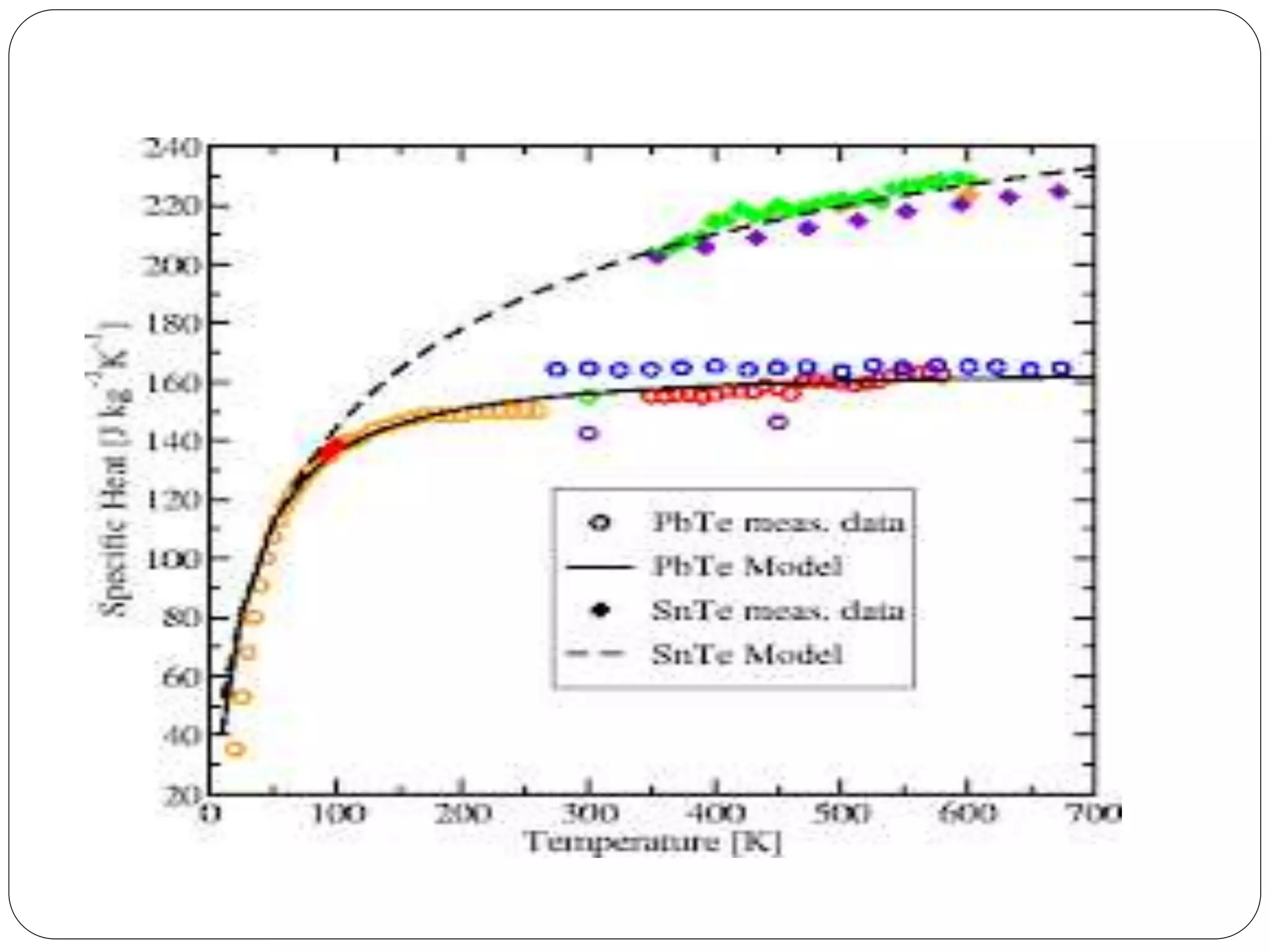

The document presents a classification of materials into three main groups: metallic (ferrous and non-ferrous) and non-metallic materials. It details various mechanical properties such as elasticity, plasticity, toughness, and others, explaining their significance in materials science. Additionally, it covers thermal properties like heat capacity and thermal expansion, along with technological properties relevant for processing materials.