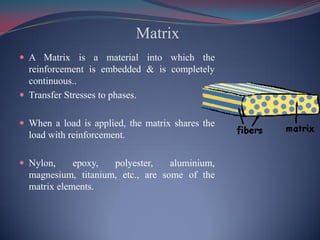

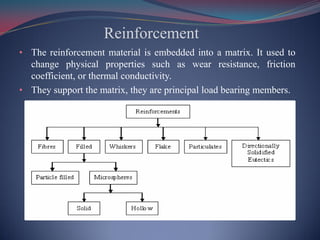

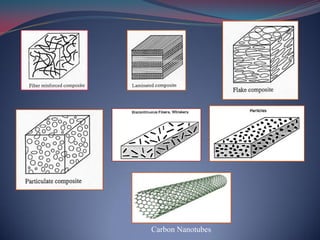

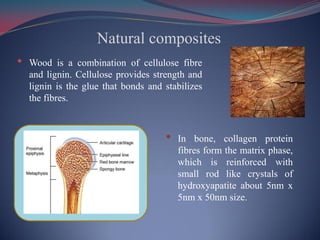

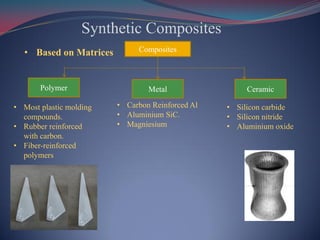

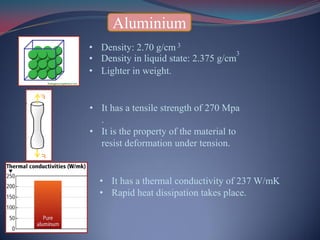

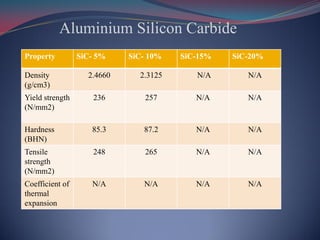

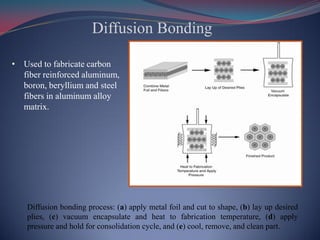

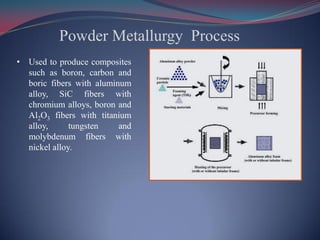

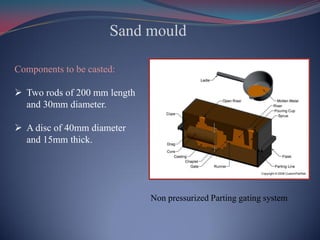

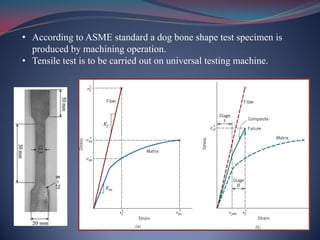

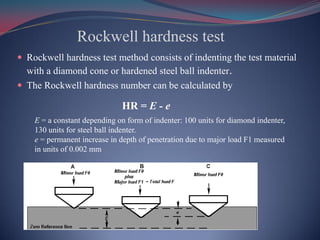

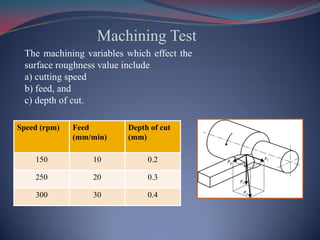

The document presents a study on fabricating and characterizing an aluminum metal matrix composite reinforced with silicon carbide particles. The objectives are to fabricate the Al-SiC MMC, characterize its tensile strength and hardness properties, and determine optimal machining parameters for good surface finish. It discusses the composite materials, matrix, reinforcement, classification of composites, and metal matrix composites. It also details the properties of aluminum, silicon carbide, and aluminum silicon carbide composites. Methods of fabricating Al-SiC MMC including stir casting and characteristics like tensile testing, hardness testing, and machining tests are explained. Relevant literature on improving mechanical properties of Al-SiC composites is reviewed.