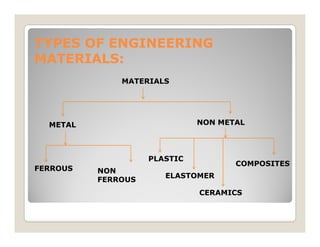

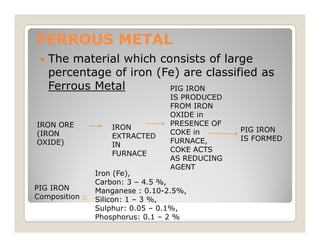

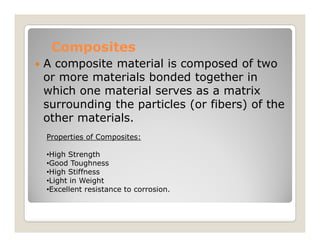

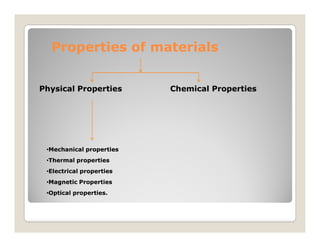

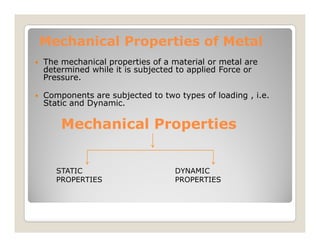

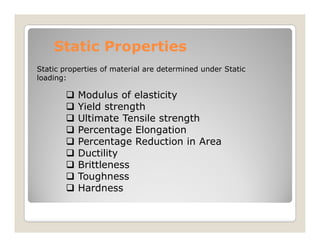

This document provides an introduction to engineering materials. It discusses the main types of engineering materials, which are divided into metals and non-metals. Metals are further divided into ferrous and non-ferrous metals. Examples of properties and applications of different materials like ceramics and composites are provided. Finally, the document discusses various mechanical properties of materials like strength, hardness, ductility etc. that are important in engineering design and analysis.