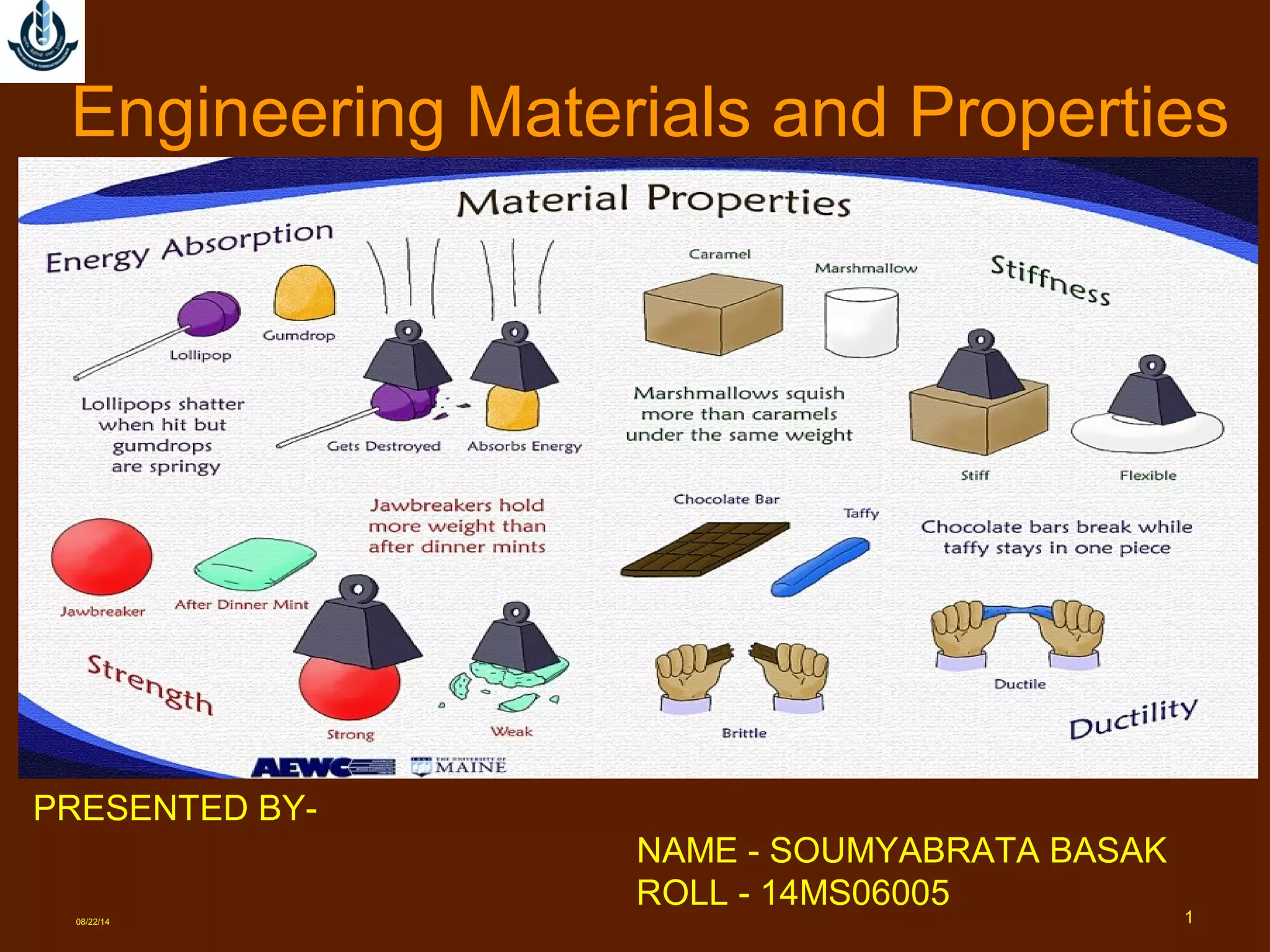

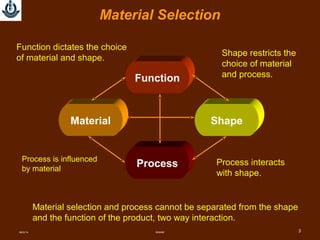

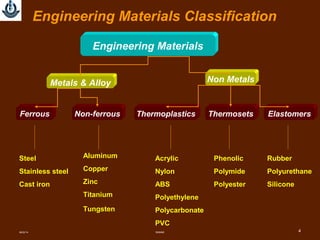

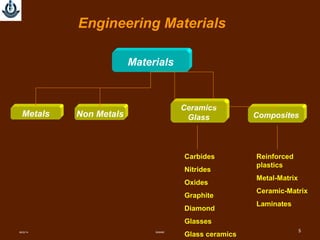

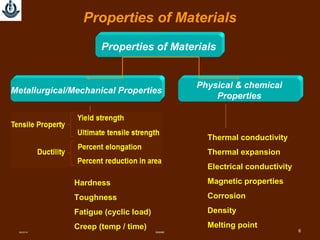

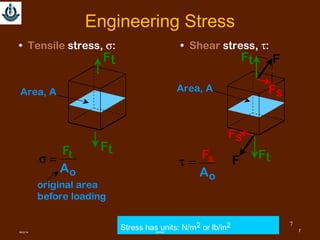

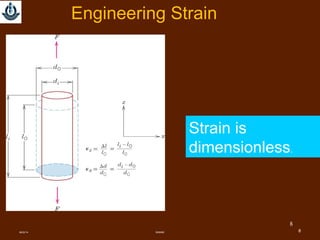

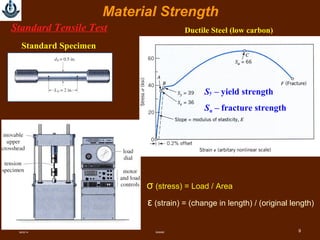

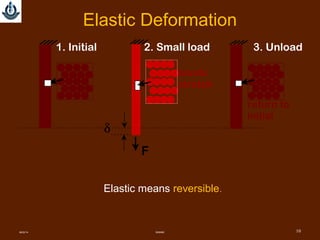

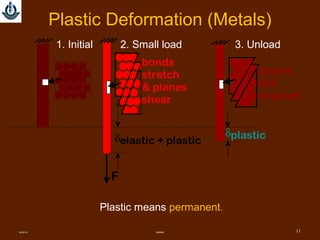

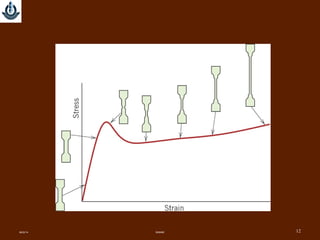

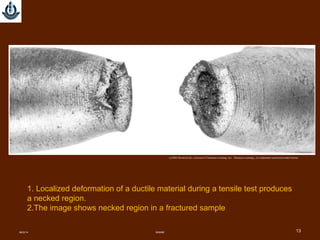

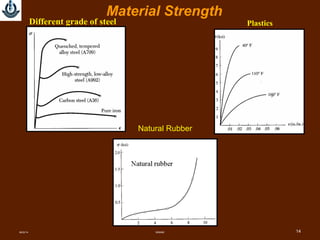

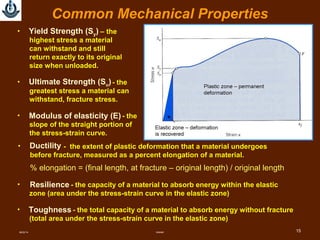

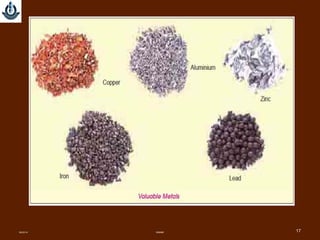

The document discusses engineering materials and their properties. It begins by defining engineering materials as the selection of appropriate materials for engineered parts based on their required properties. It then classifies engineering materials into metals and alloys, non-metals, ceramics, glasses, composites. Key mechanical and physical properties of materials are outlined including hardness, toughness, thermal and electrical conductivity. Common material testing methods like tensile tests are described which measure properties such as yield strength, ultimate strength, and ductility. Different material grades are discussed along with advantages of metallic materials.