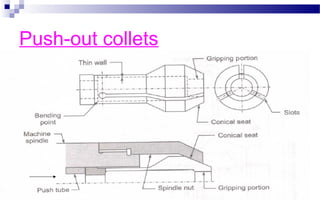

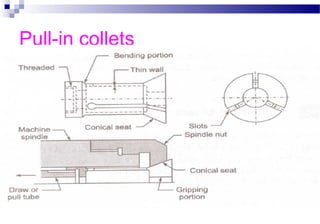

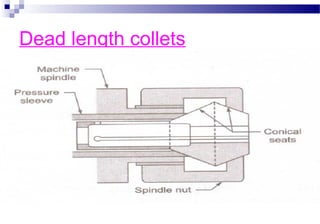

The document discusses different types of turning fixtures and mandrels used to securely hold workpieces for machining operations on lathes. Turning fixtures are cheaper than milling and allow for asymmetric jobs to be machined. Fixtures must be carefully designed for operator safety, accuracy, and proper clamping to the faceplate. Mandrels are used internally to locate cylindrical workpieces and come in tapered, clamping, expanding, and threaded varieties to suit a range of bore sizes and provide accurate concentricity.