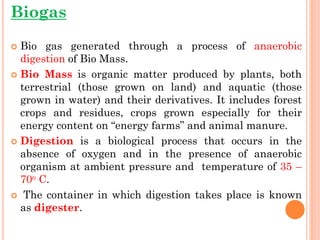

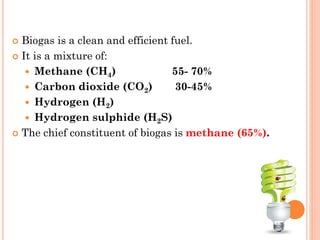

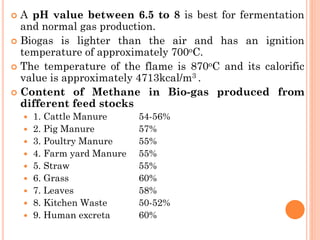

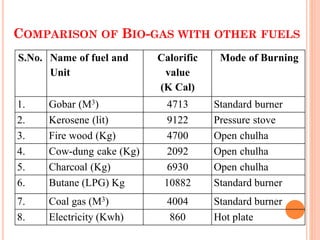

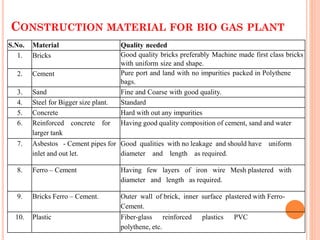

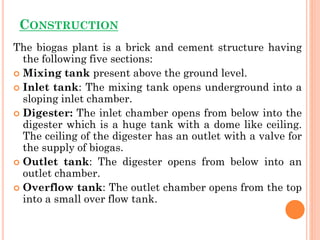

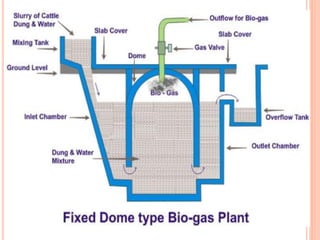

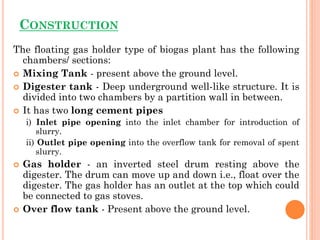

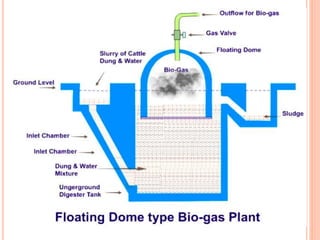

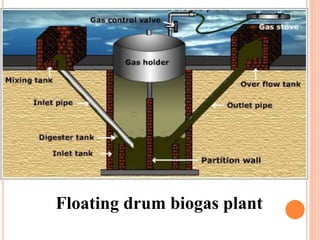

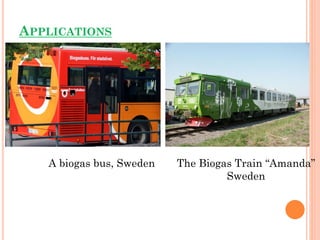

The document discusses biogas plants and provides details about different types of biogas plants including fixed dome plants, floating gas holder plants, KVIC plants, Pragathi plants, and Janata plants. It describes the construction, working, raw materials used, and advantages and disadvantages of each type of plant. Key points covered include how biogas is produced via anaerobic digestion of biomass, the components of biogas, and uses of biogas as a fuel.