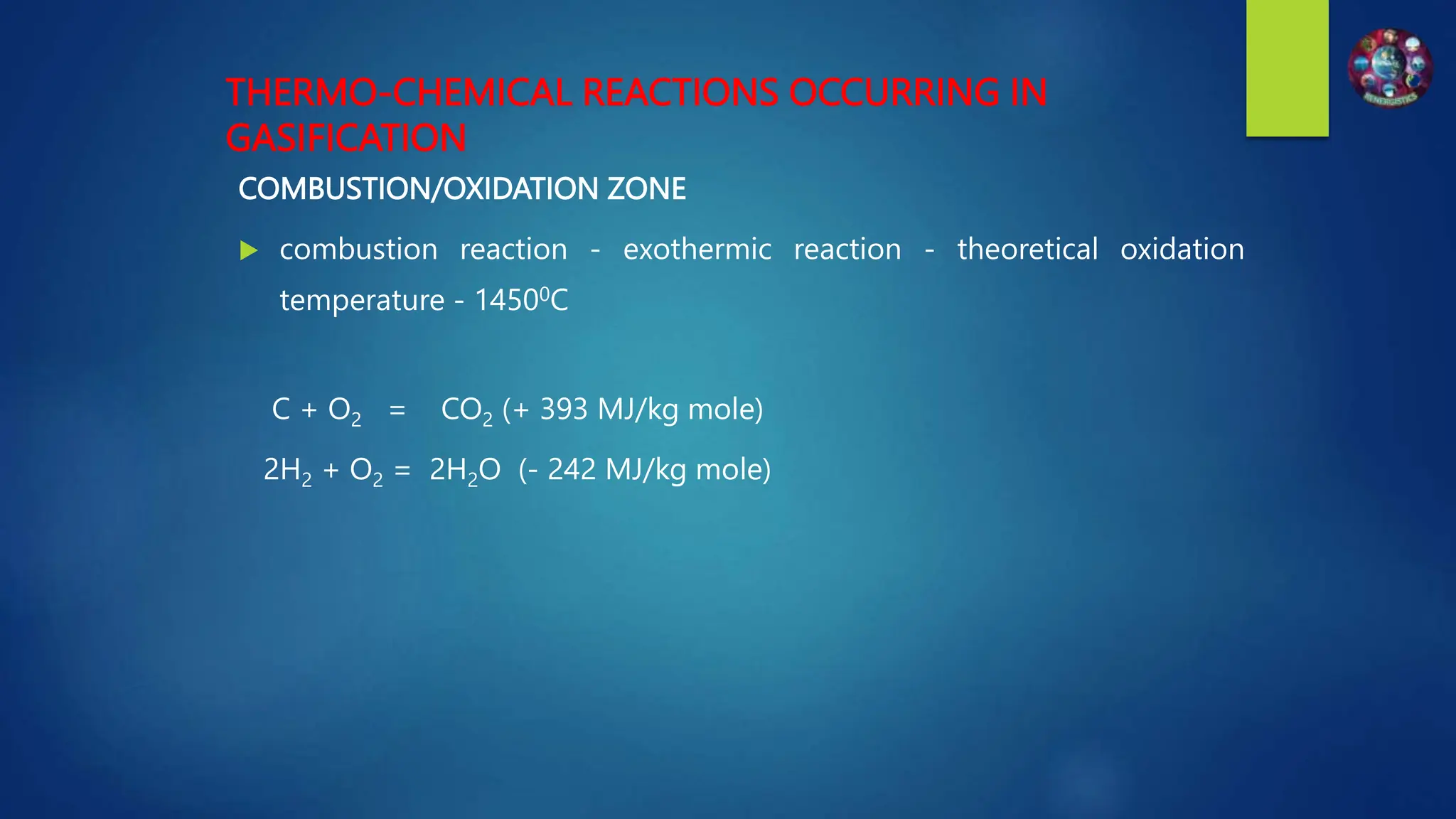

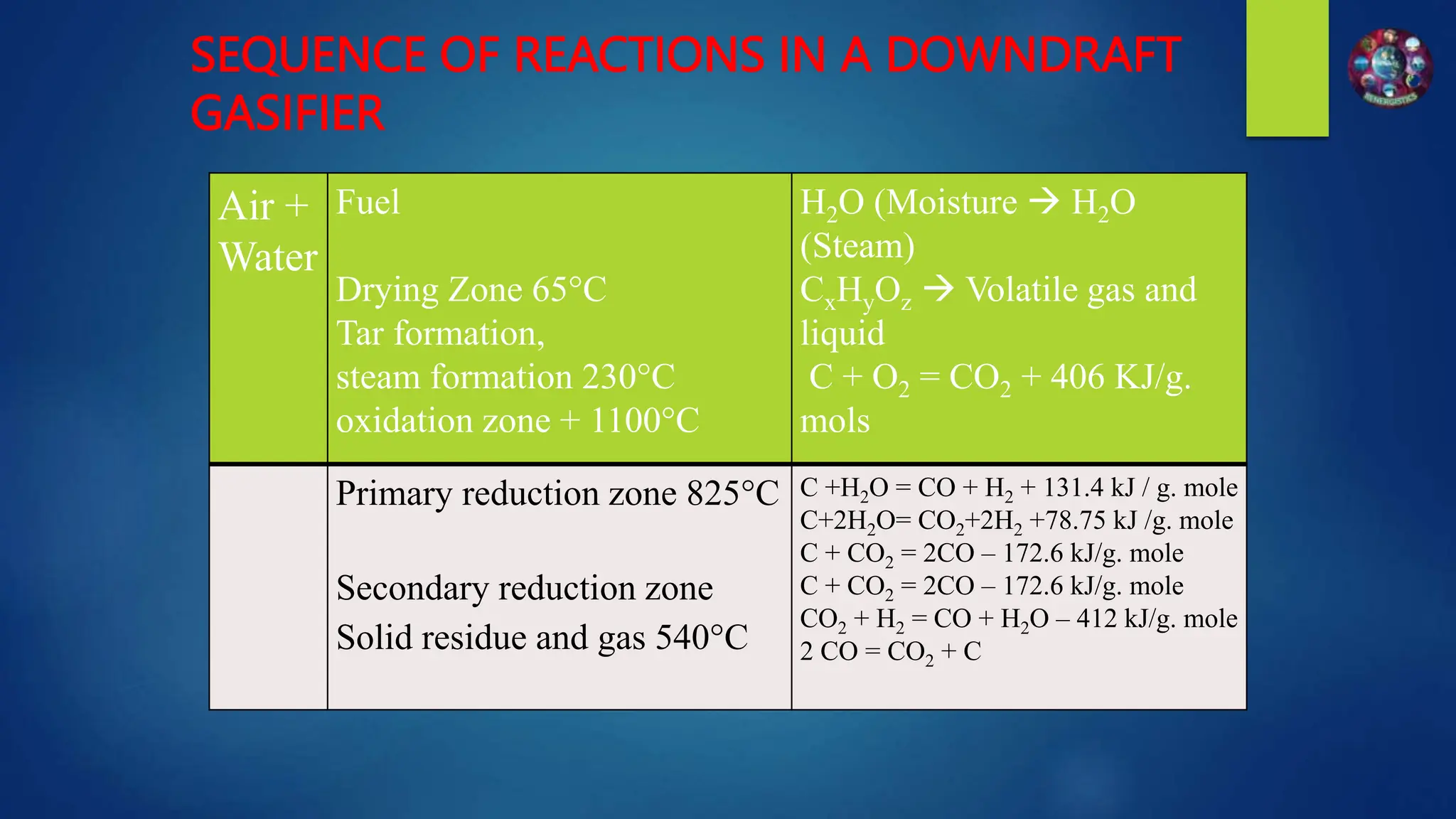

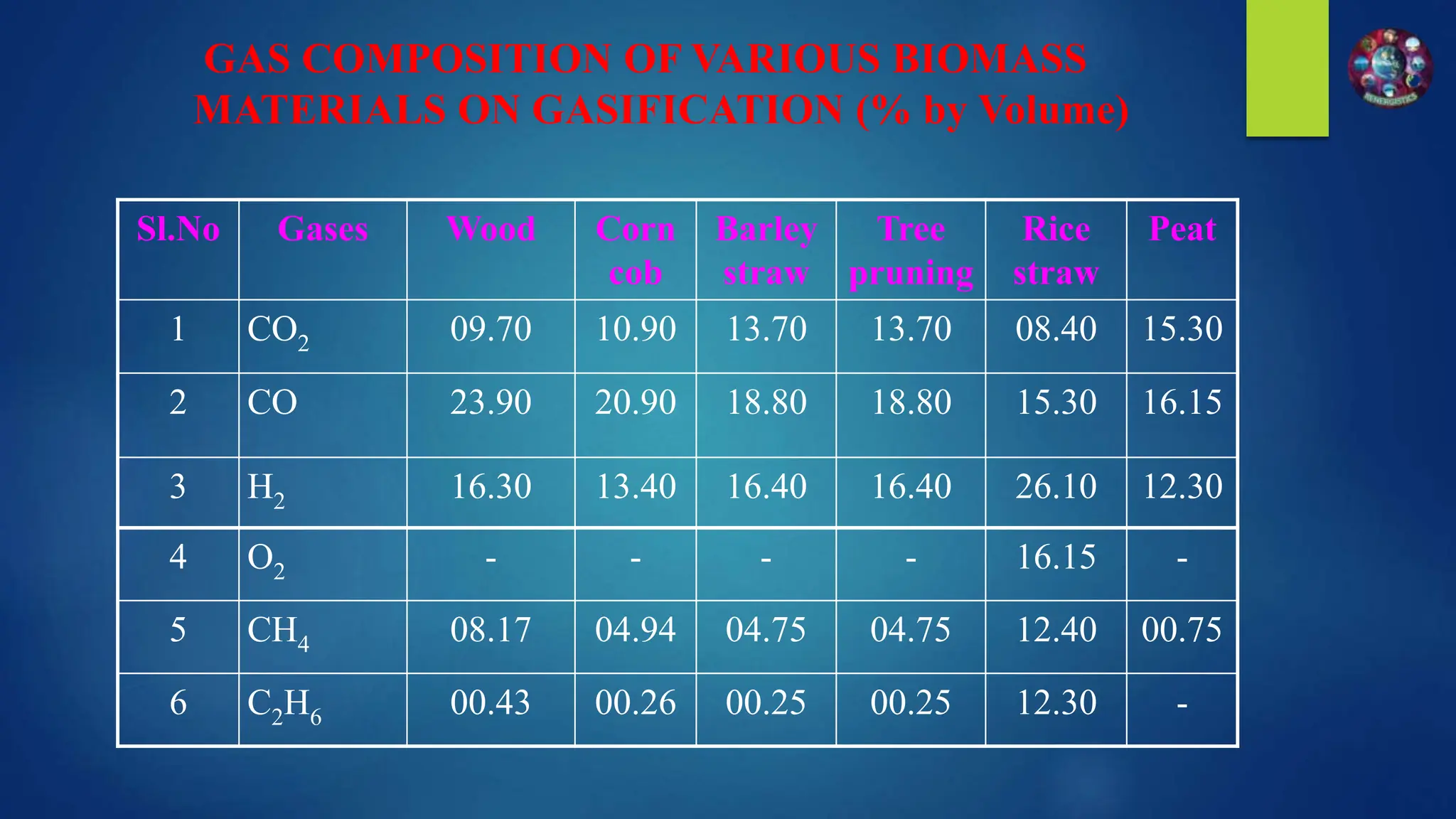

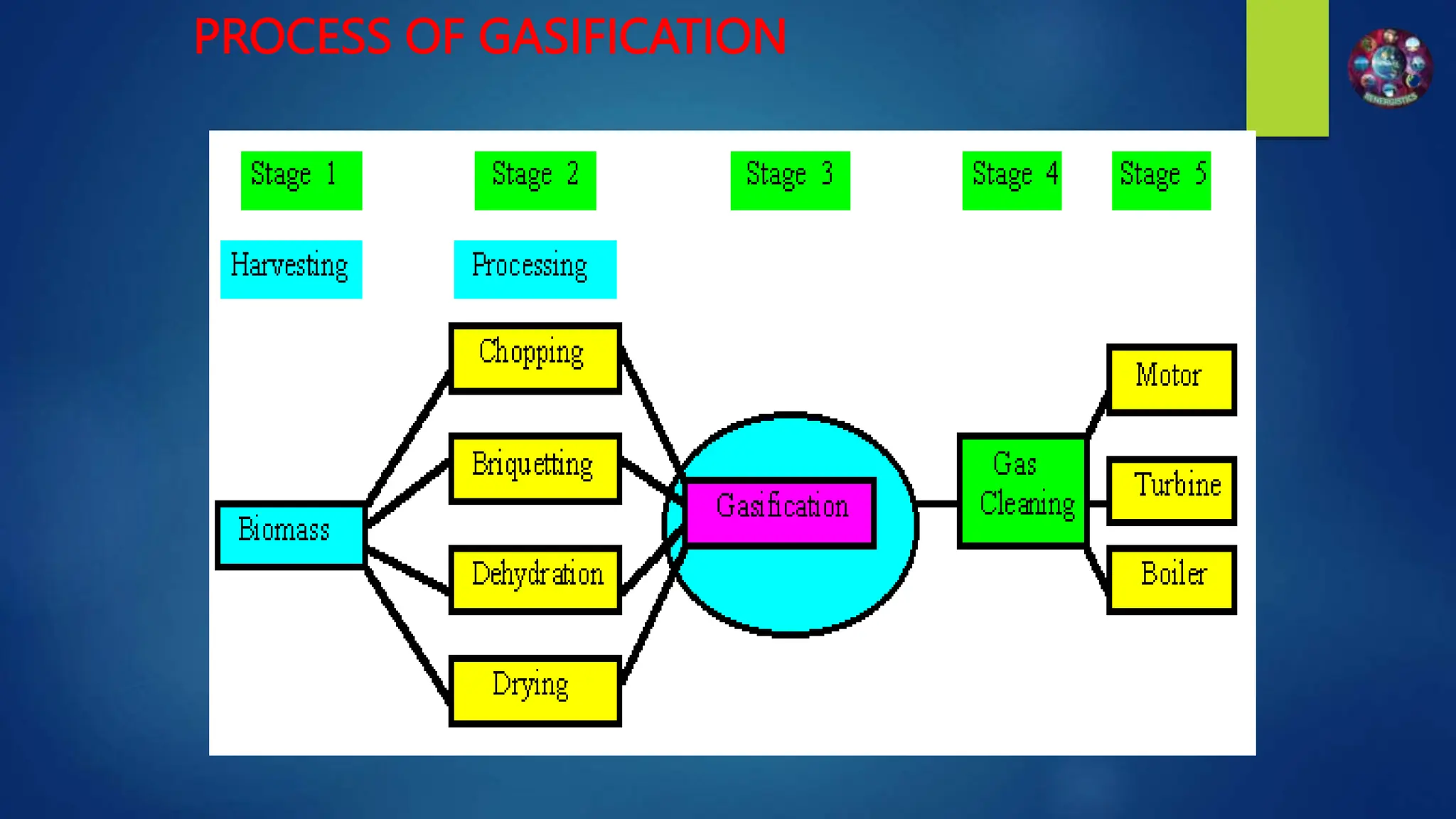

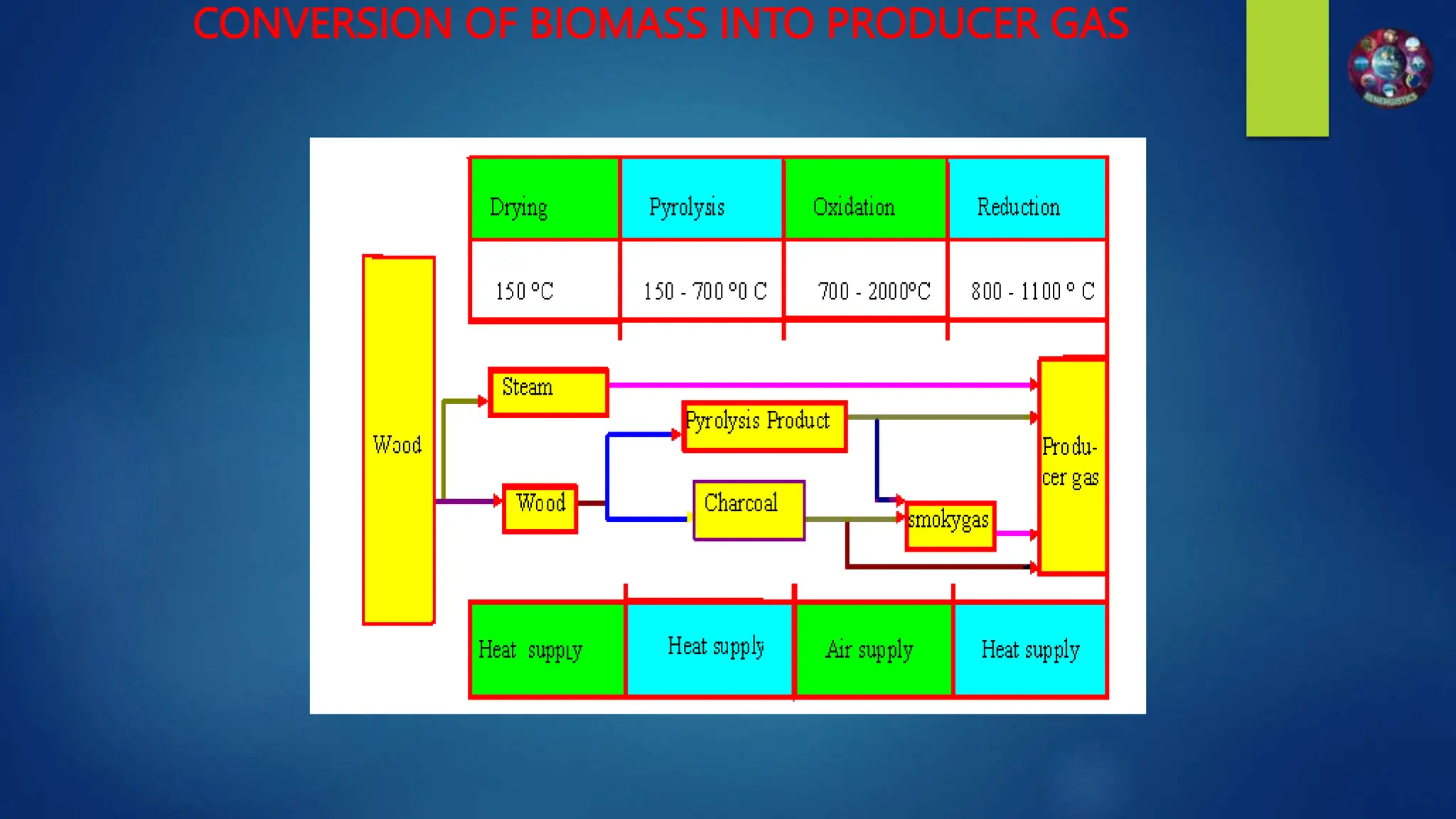

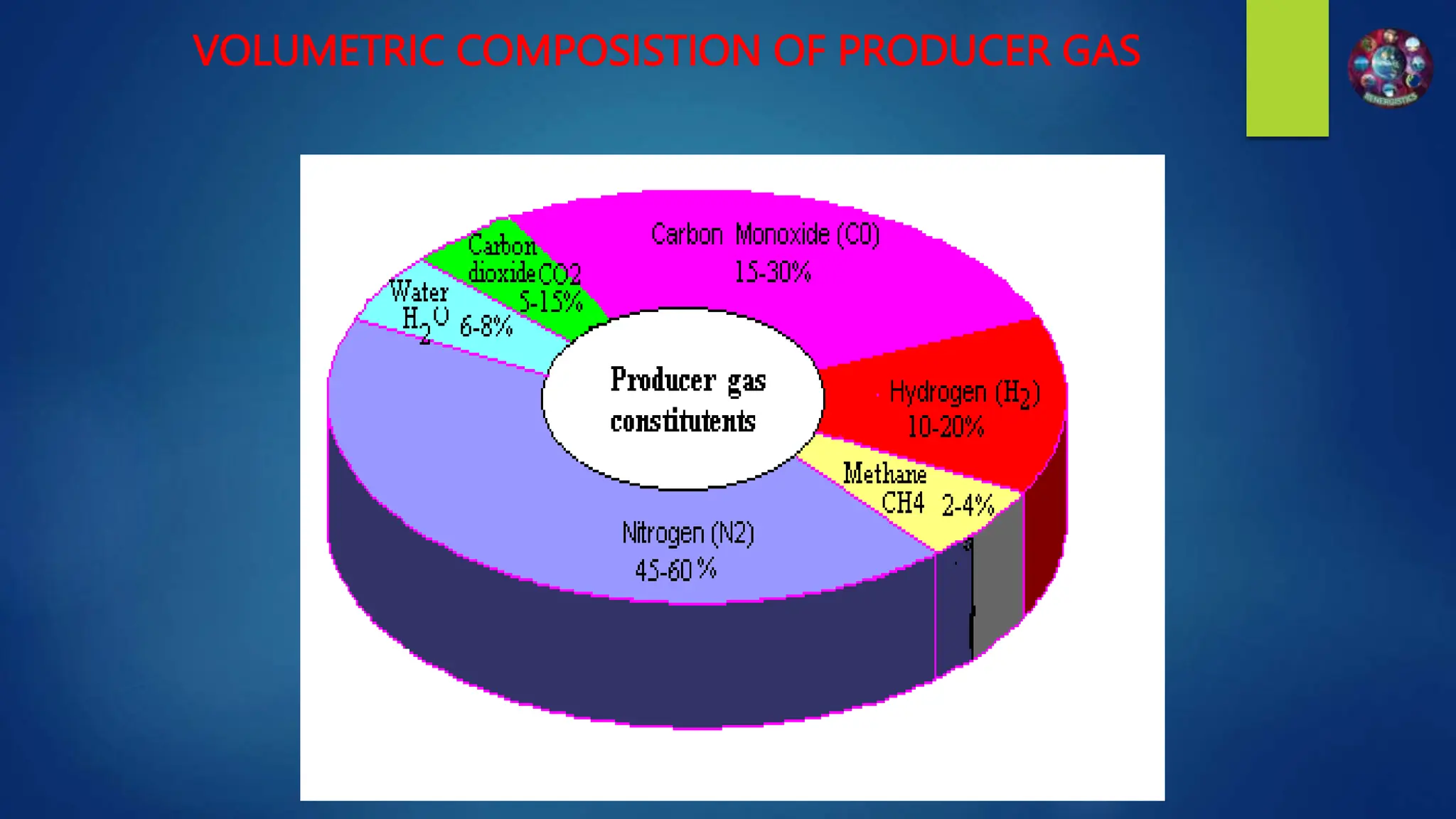

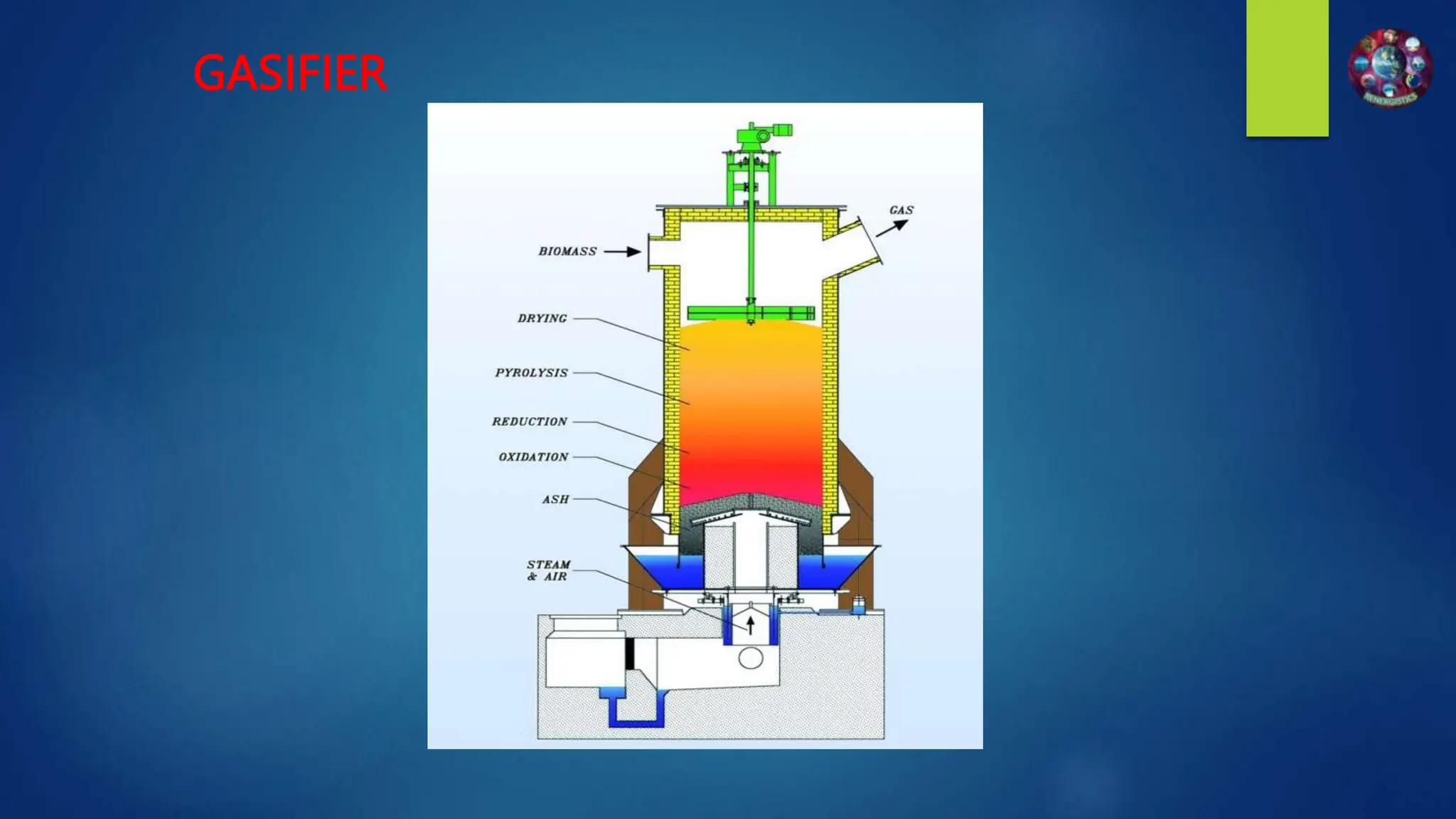

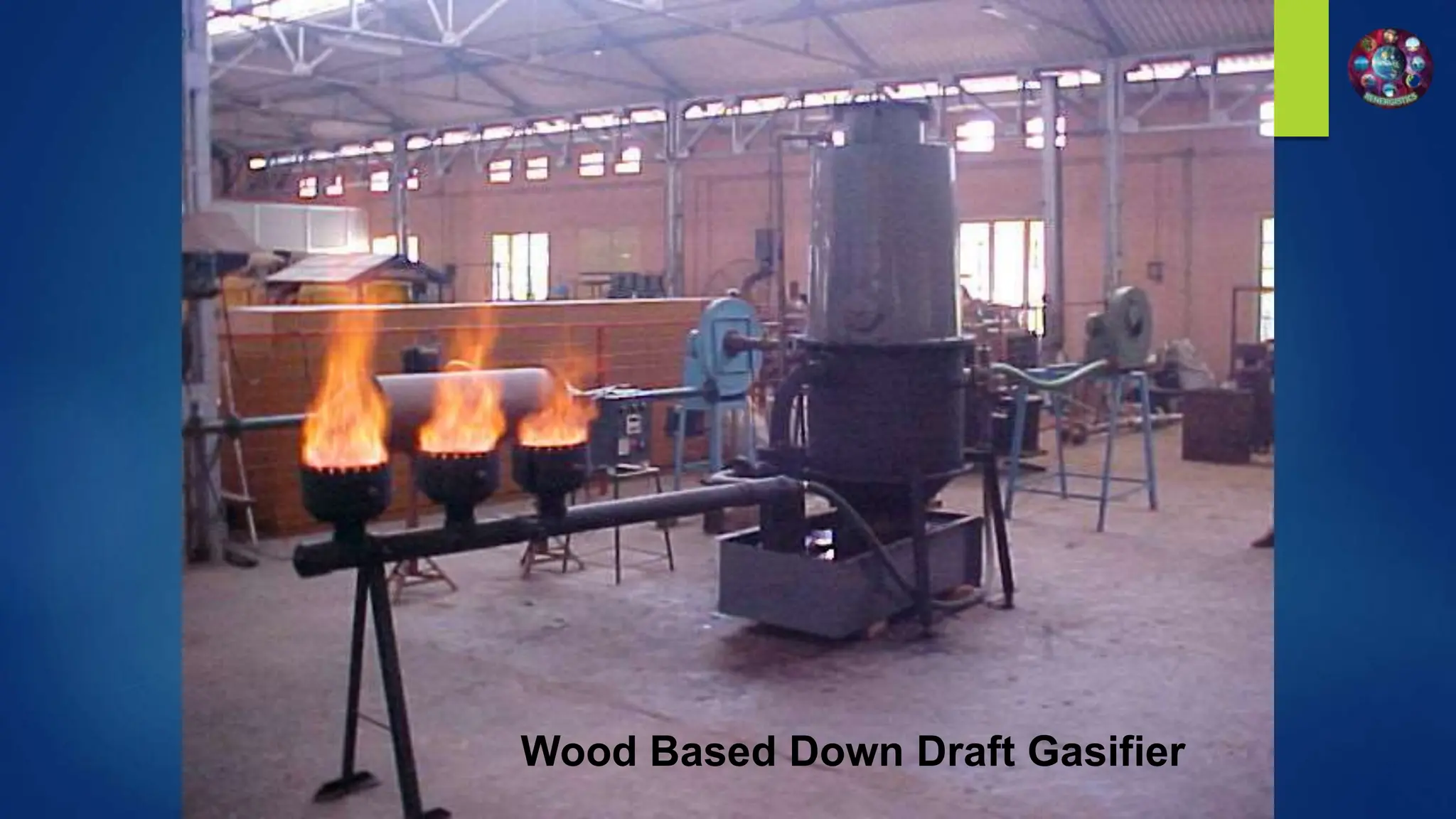

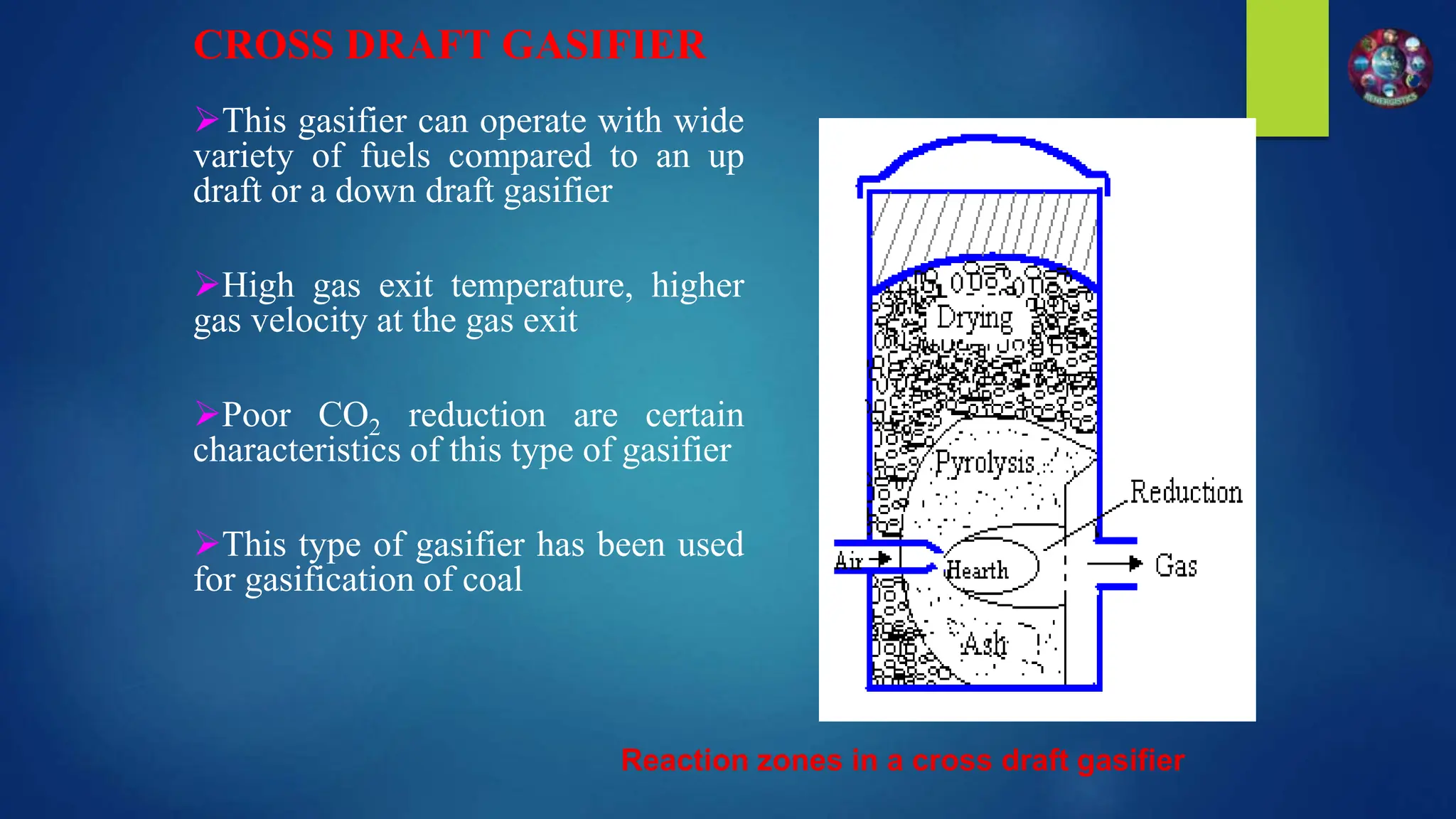

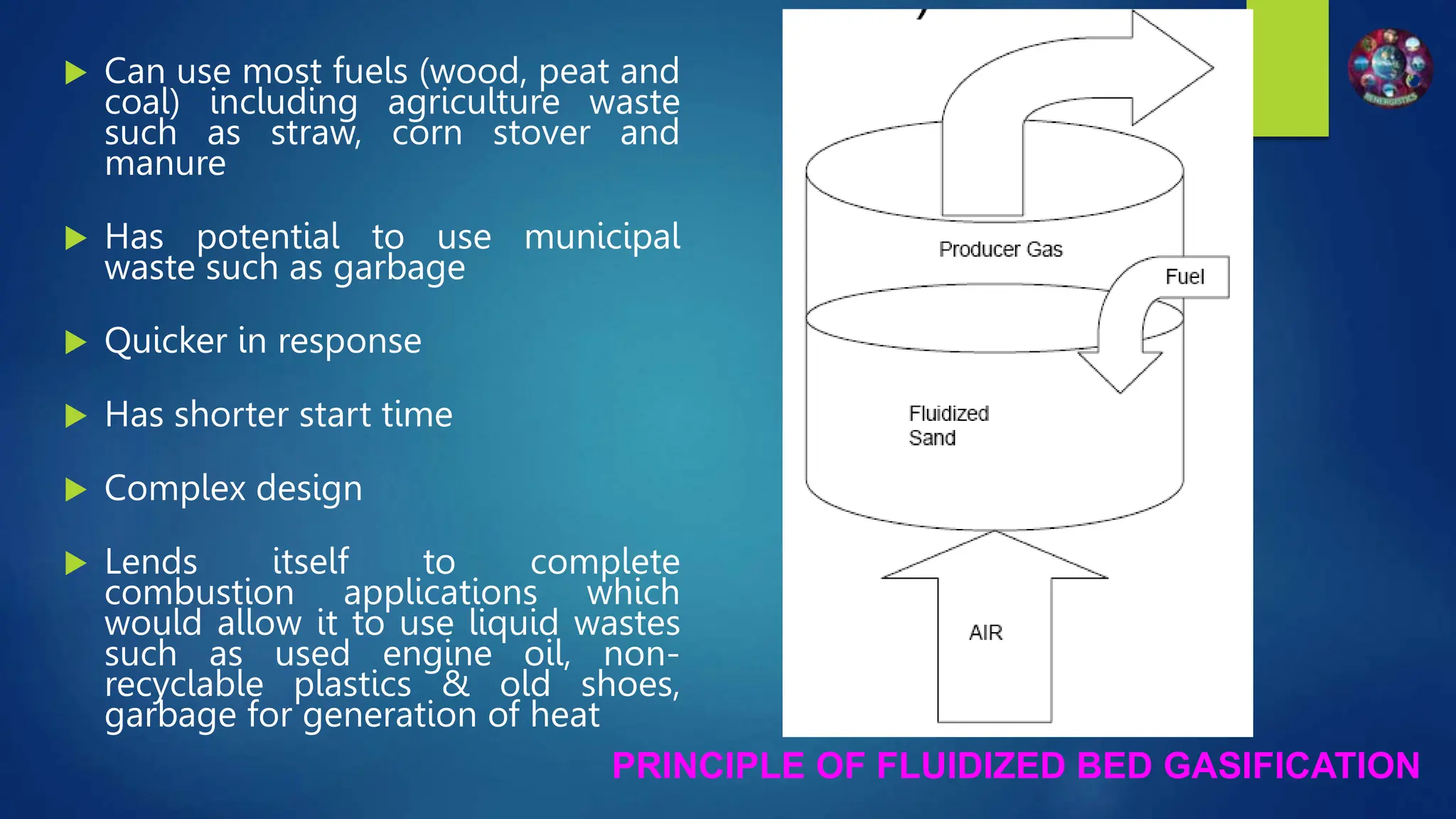

This document discusses biomass gasification, a thermo-chemical process that converts carbon-containing biomass into producer gas through partial oxidation with air or steam. Key components of gasifiers and factors influencing their performance, such as fuel qualities and equivalence ratio, are explained, alongside the environmental benefits of using biomass energy. Various types of gasifiers, including down draft, twin drum, and fluidized bed gasifiers, are also analyzed for their operational characteristics and fuel applicability.