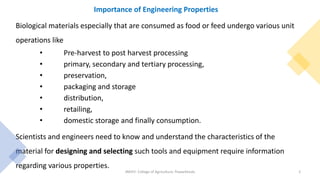

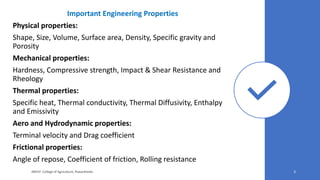

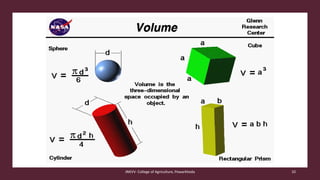

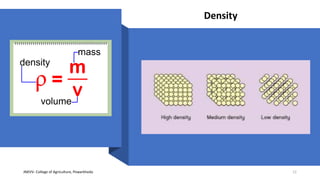

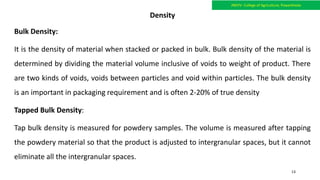

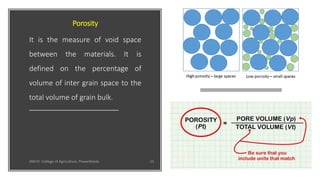

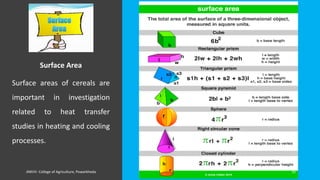

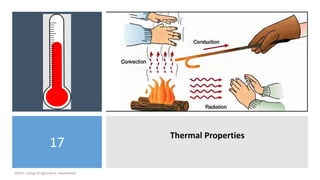

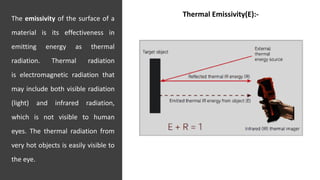

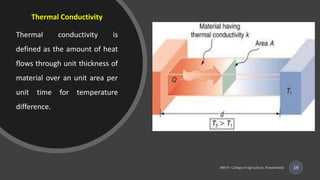

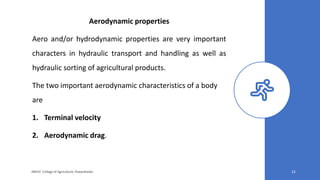

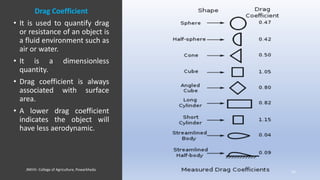

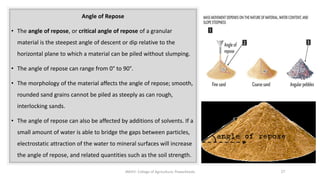

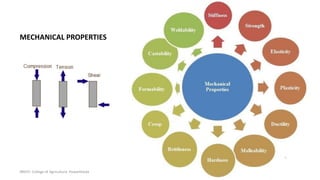

The document discusses the engineering properties of cereals, pulses, and oilseeds, highlighting the importance of understanding these properties for agricultural processing and food engineering. It covers various physical, mechanical, thermal, and aerodynamic properties that impact processing operations such as heating, cooling, and material handling. The paper emphasizes the need for accurate measurement and application of these properties in designing tools and machinery in agriculture.