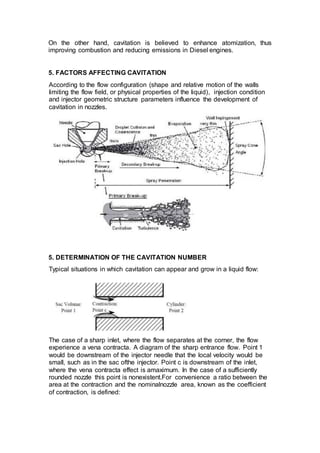

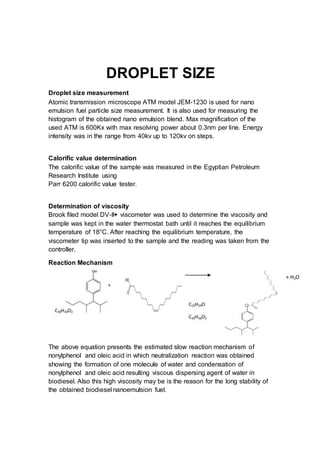

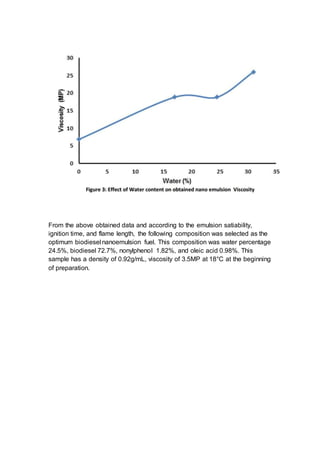

The document discusses fuel injection and spray formation in diesel engines. It examines the effects of injection pressure on engine performance and emissions. The results of an experiment showed that brake thermal efficiency peaked at an injection pressure of 200 bars, while brake specific fuel consumption was lowest. CO and smoke emissions decreased with higher injection pressure, while UHC first decreased and then increased as pressure became too high. Optimal injection pressure was found to be 200 bars for a 20% biodiesel blend. Cavitation in the fuel injector nozzle enhances spray atomization and improves combustion. Nozzle geometry and injection conditions can affect cavitation.

![Some possible sources for atomization are shortly treated in the

following.

Aerodynamic shear forces amplify the surface waves created by the

turbulence in the nozzle hole. The waves separate from the jet and form

droplets. There are two reasons why this aerodynamic source is less

important. First, this process is time dependent, but it is known from

experiments that jets break immediately at the exit of the nozzle. Second,

aerodynamic breakup is a surface effect, so it cannot explain disintegration of

the inner structure.

Relaxation of velocity profileAt the wall inside the nozzle a no-slip

boundary conditions exists. When the liquid exits the nozzle, the velocity

profile will transform into a uniform one. In order to realize that the outer

region of the liquid accelerates, which may cause instabilities and ultimately

result in breakup into droplets. However, in modern diesel engines the length

to diameter ratio of the nozzle hole is typically small ([ L/D]nozzle = 5), so

probably the flow in the nozzle has no time to develop.

Turbulence The presence of radial turbulent velocity fluctuations in the jet

results, if strong enough to overcome the surface tension, in formation of

droplets. Turbulence-induced primary breakup is considered one of the most

important mechanisms in high pressure applications.

Fuel Spray Characteristics

The most important diesel fuel spray characteristics may be classified as

• Macroscopic quantities such as:

– Spray tip penetration

– Cone angle

• Microscopic quantities such as:

– Droplet size

All fuel spray characteristics influence the combustion process

and engine performance.

-Fuel spray tip penetration(Lp (is defined as the maximal distance measured

from the injector to the spray tip.

-Spray cone angle(θ) is defined as the angle between two straight lines

originating from the orifice exit of the nozzle and being tangent to the spray

outline. This angle usually ranges from 5 to 30.

-Droplet size is usually measured on an average basis by the medium

diameter of the droplets, called the Sauter mean diameter.](https://image.slidesharecdn.com/1f739297-ccb9-4405-8c78-dd490ba4d4f5-160128203033/85/FUEL-INJECTION-AND-SPRAY-FORMATION-22-320.jpg)