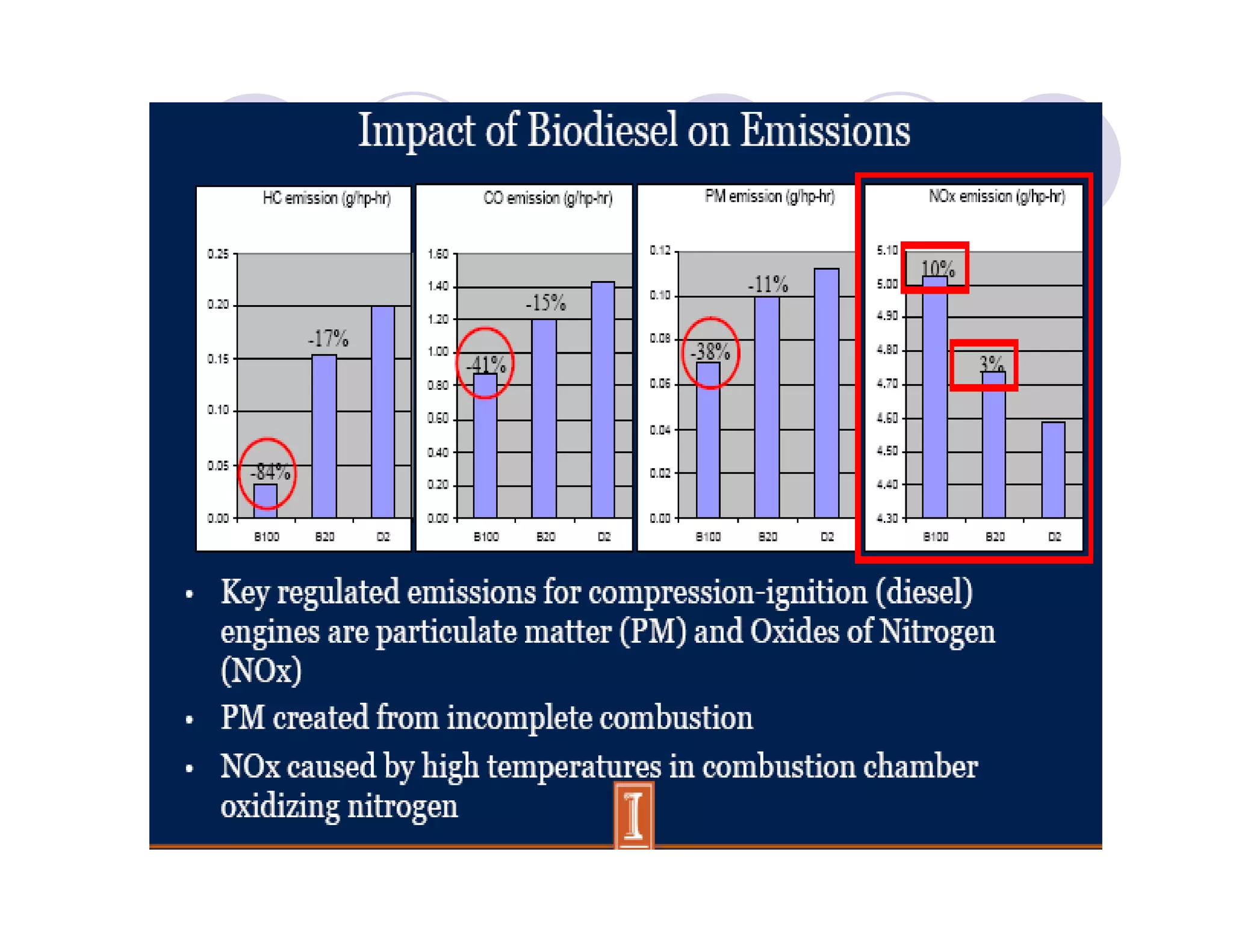

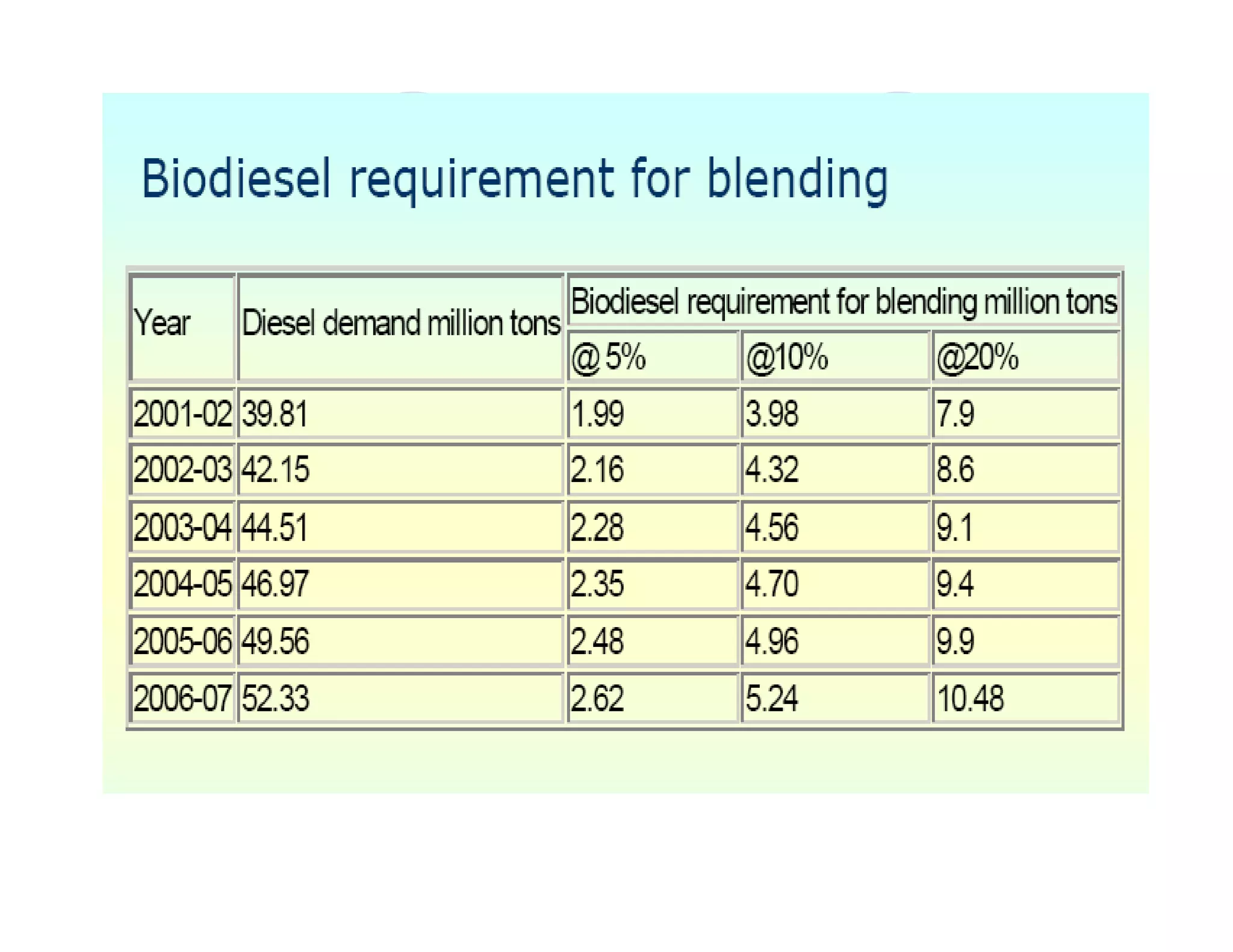

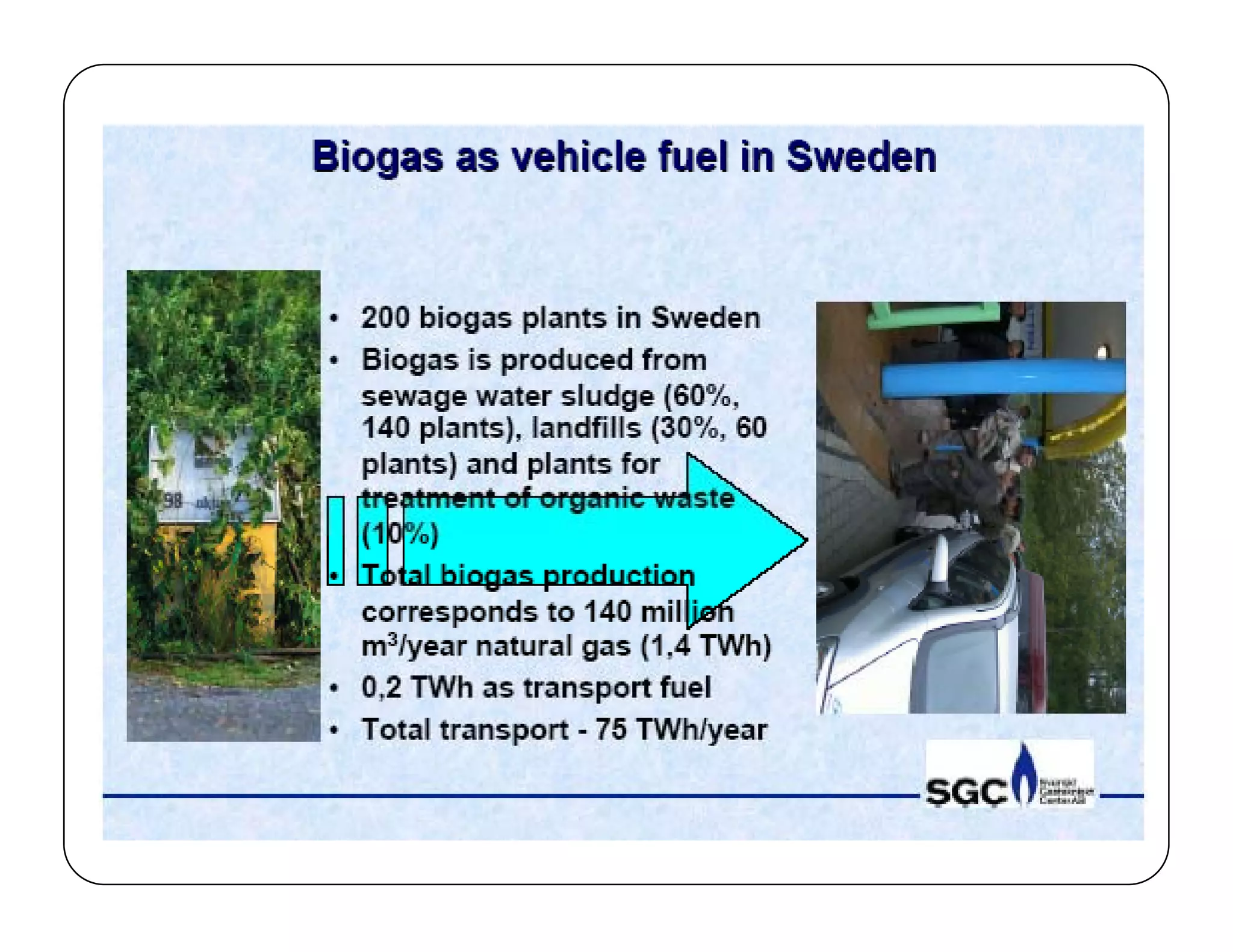

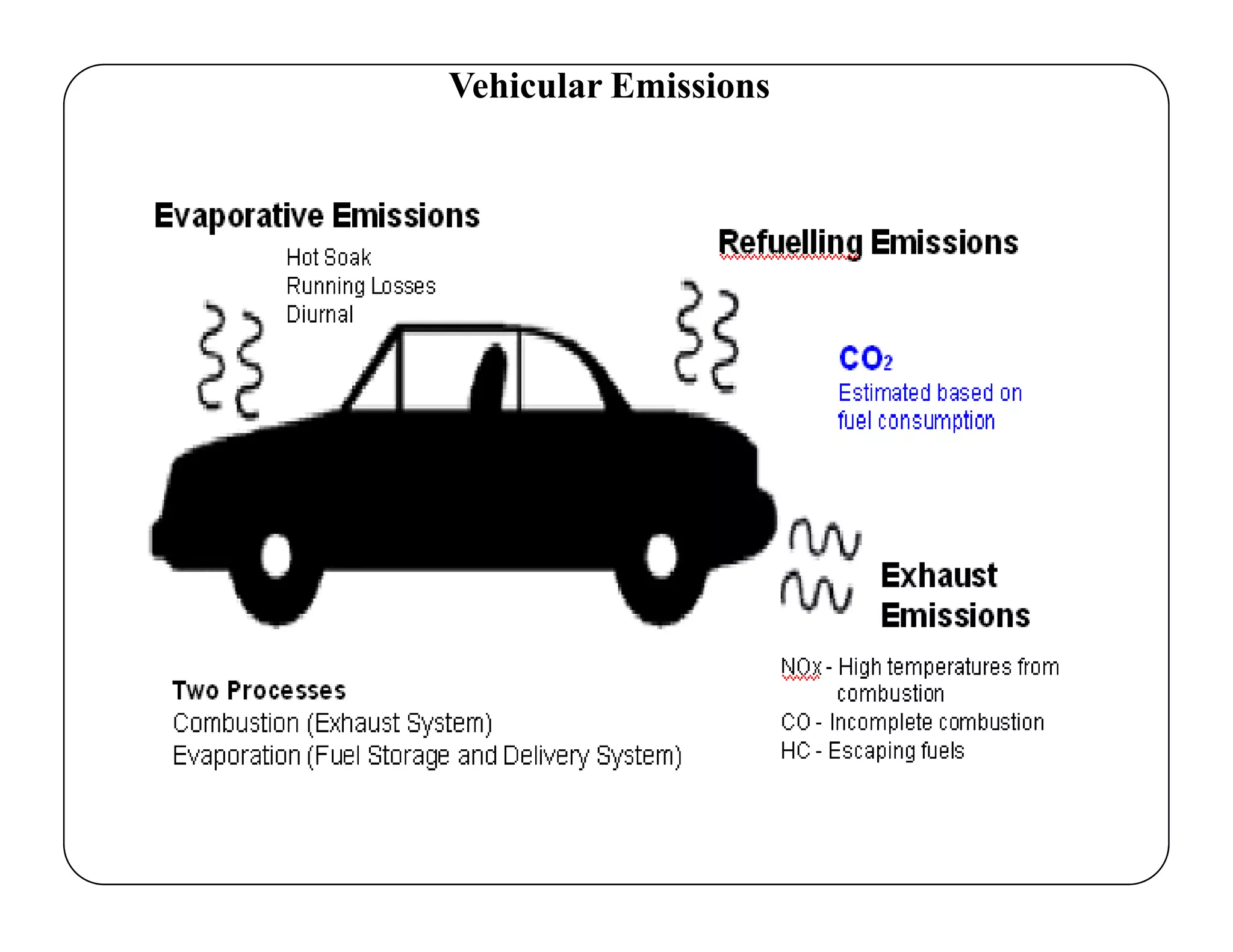

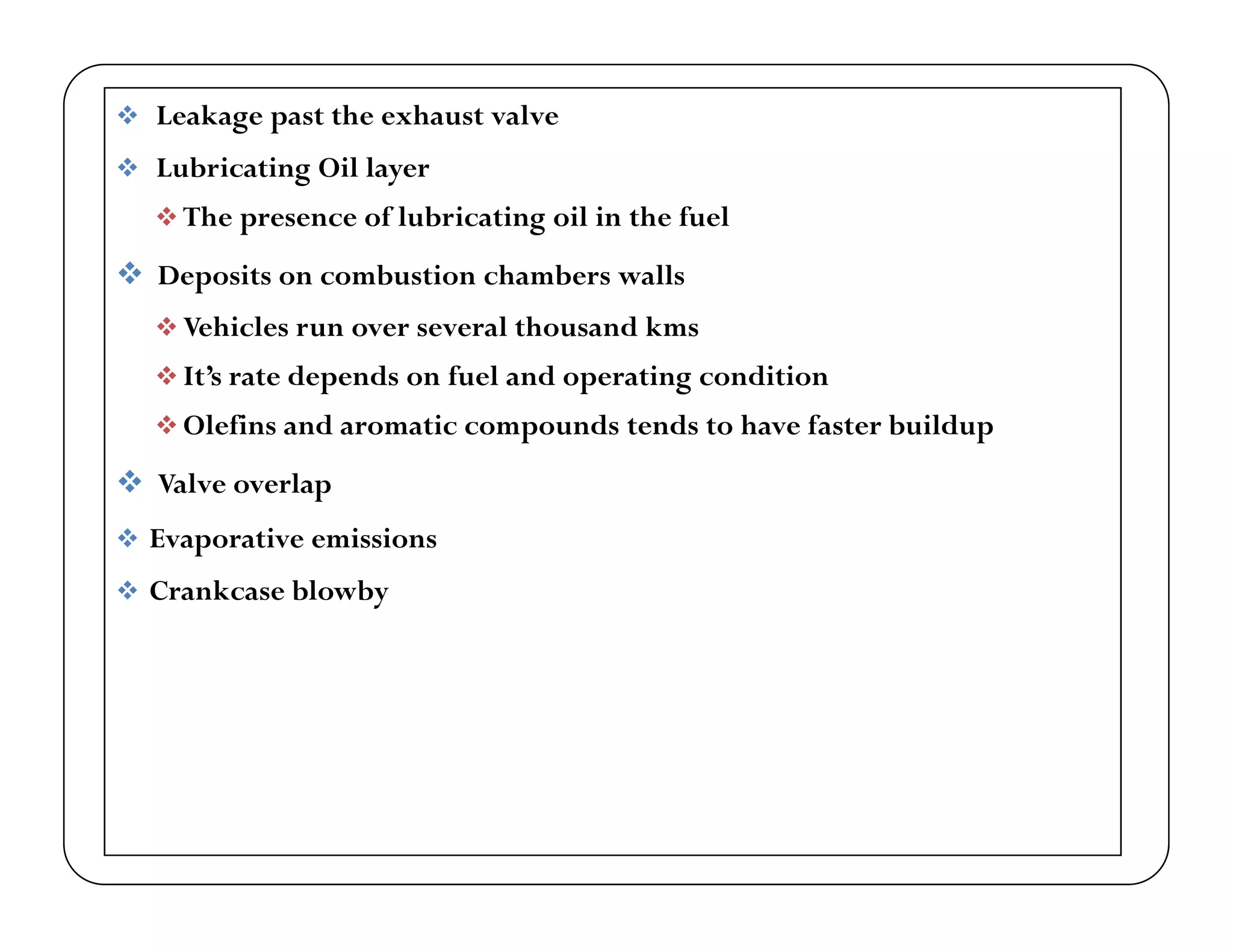

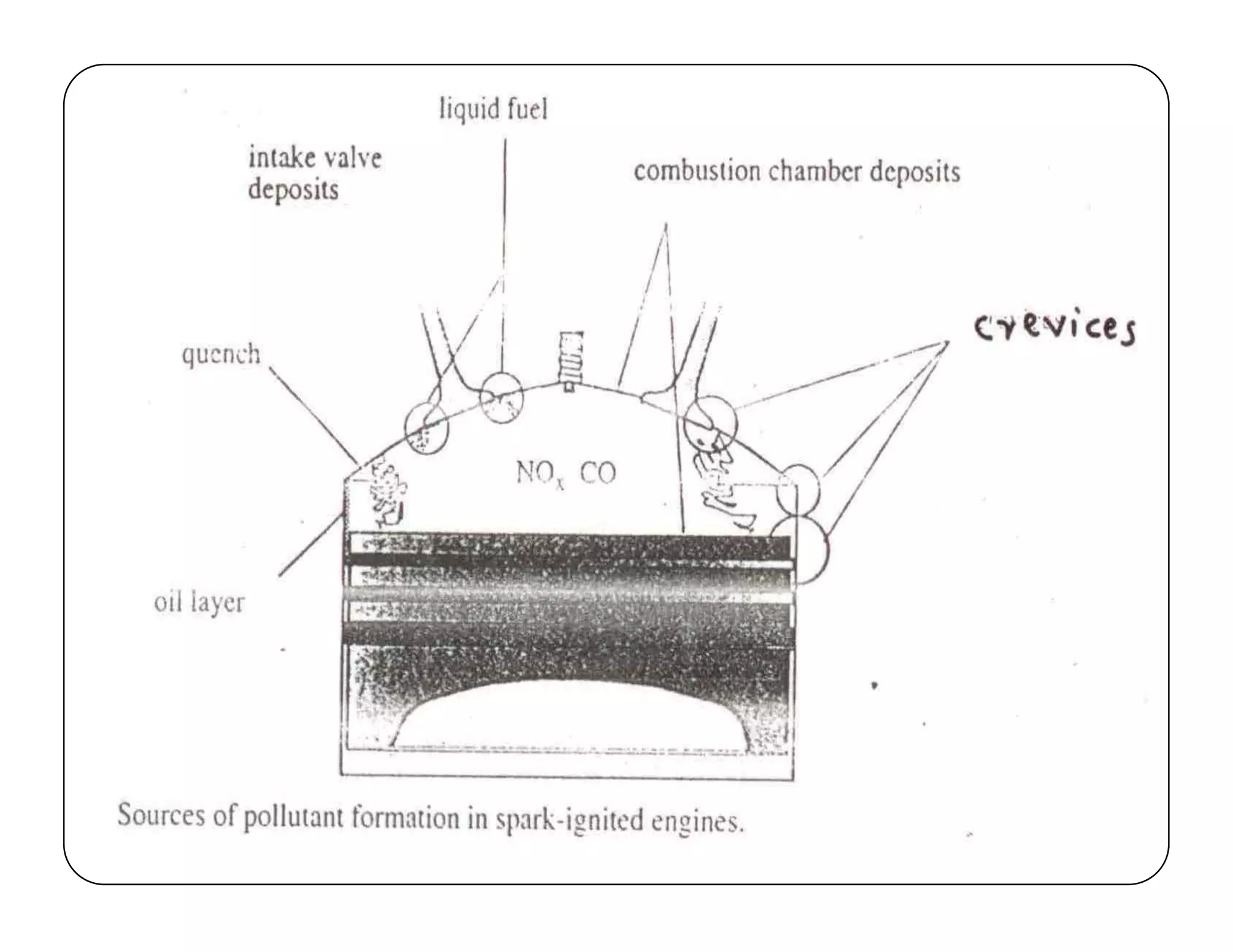

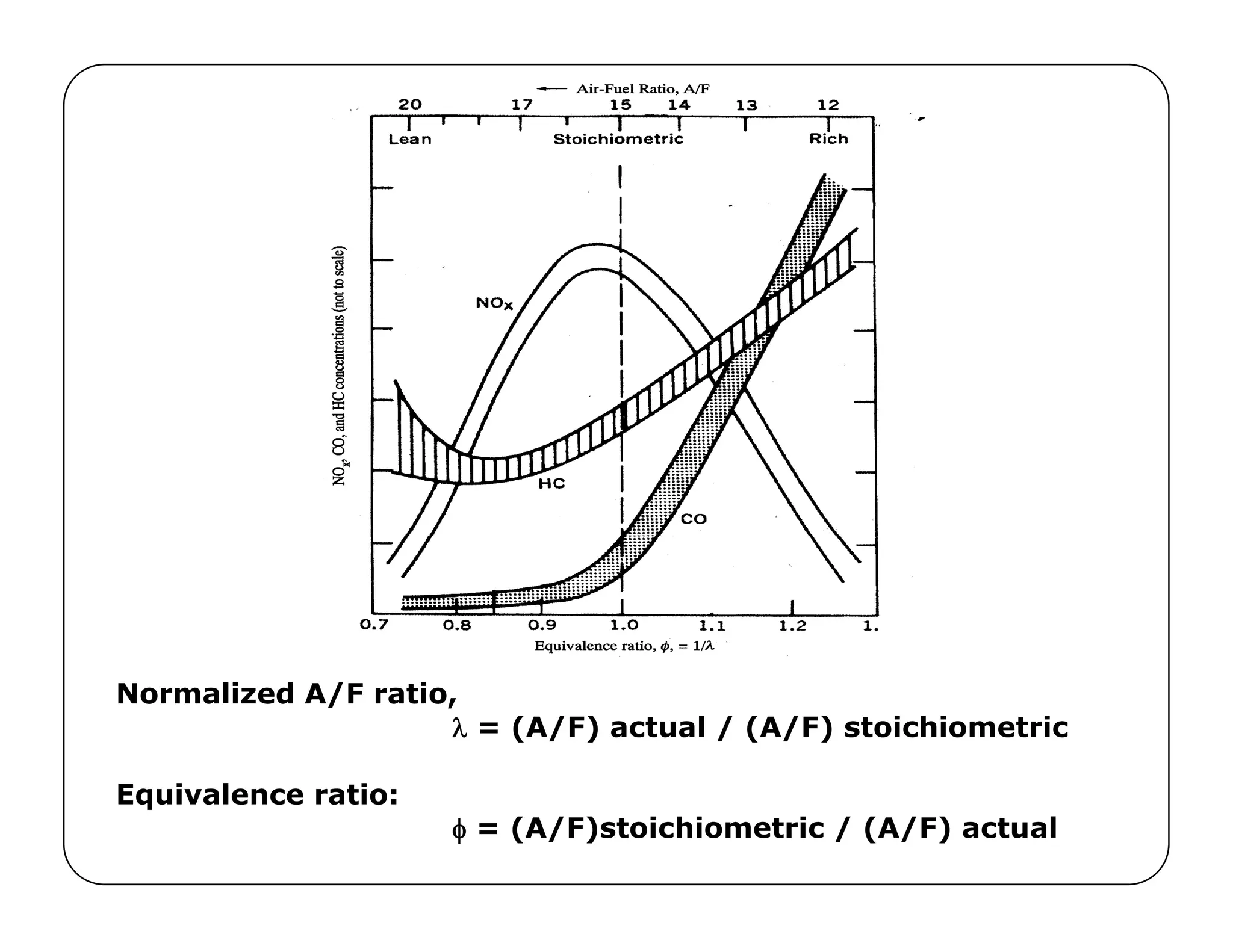

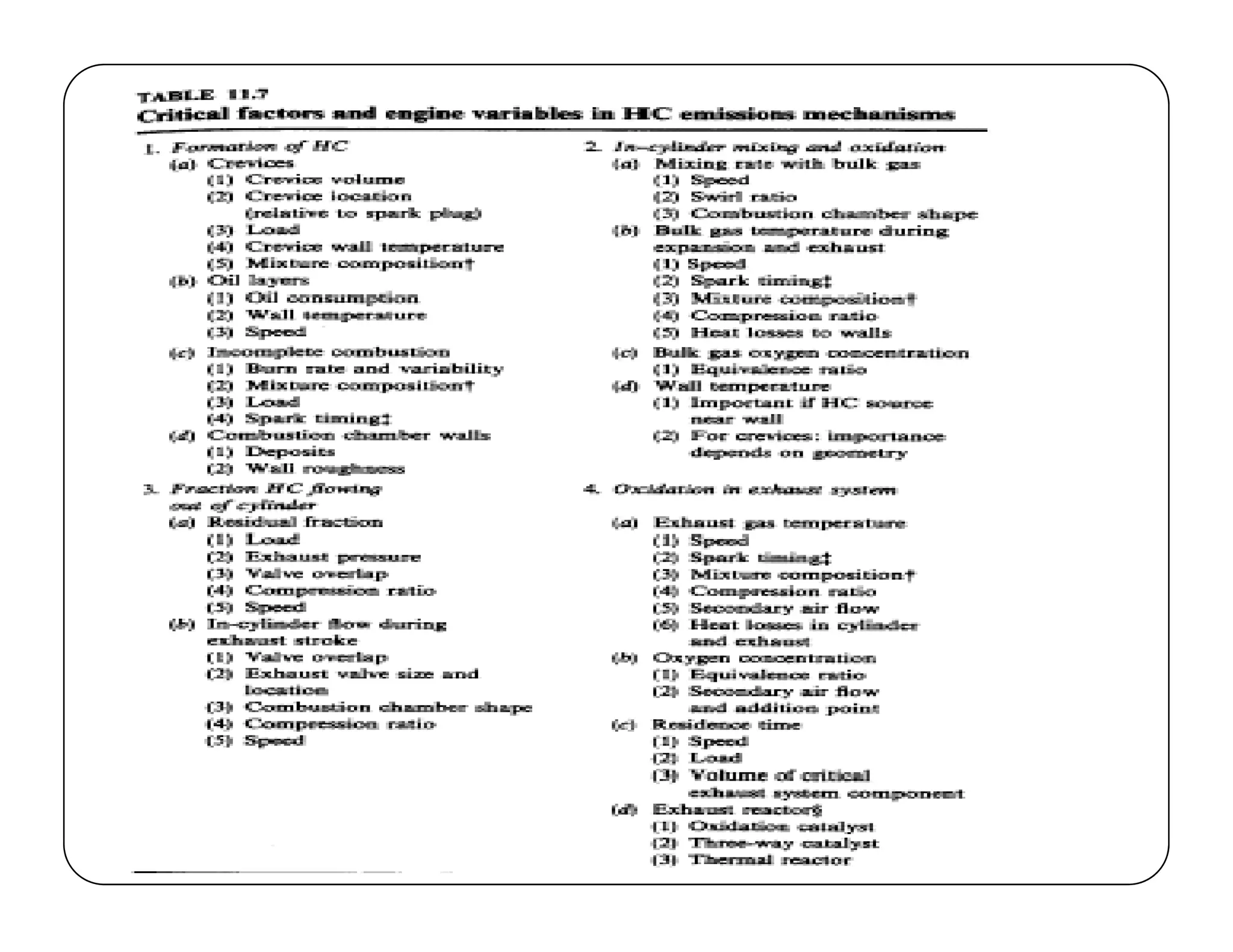

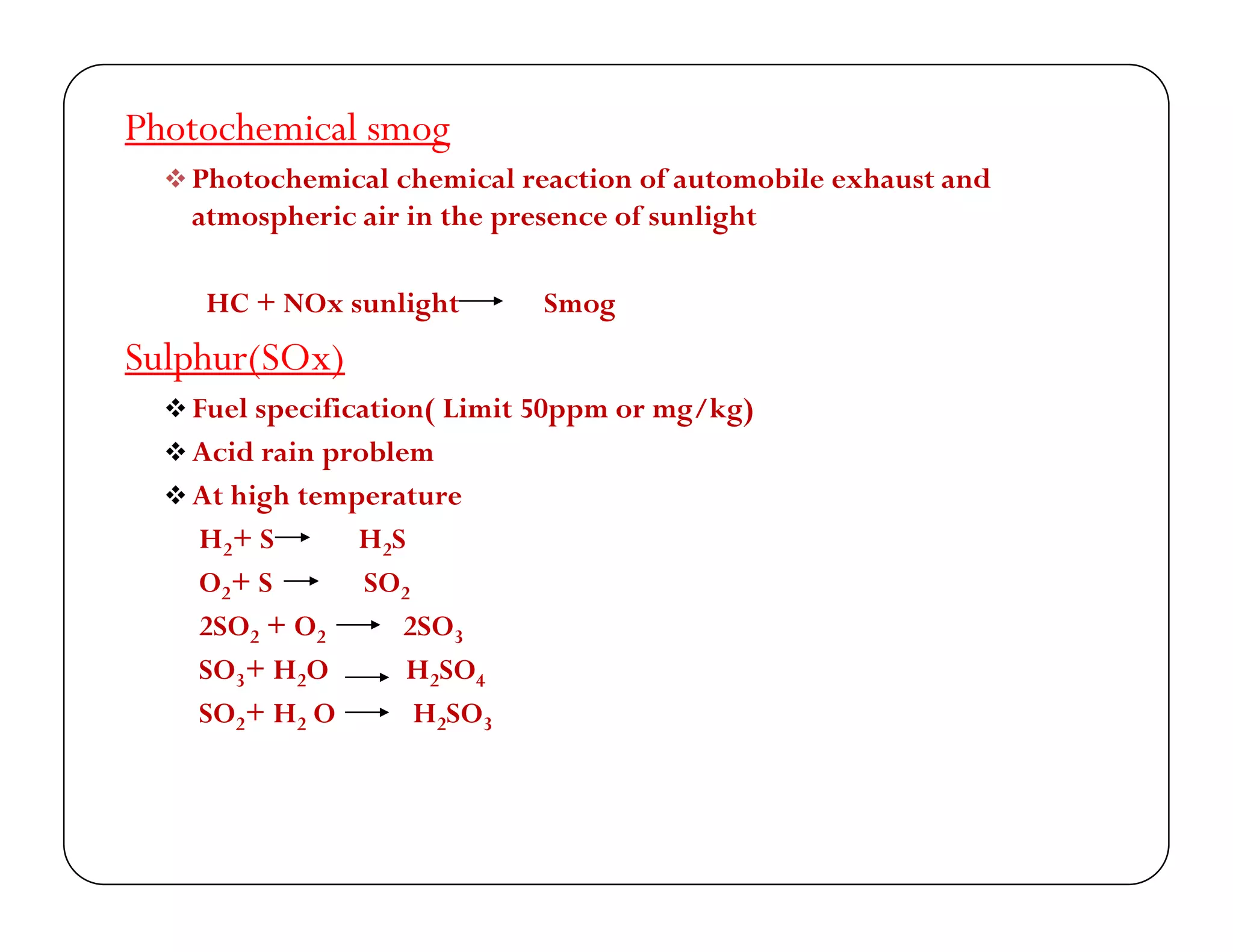

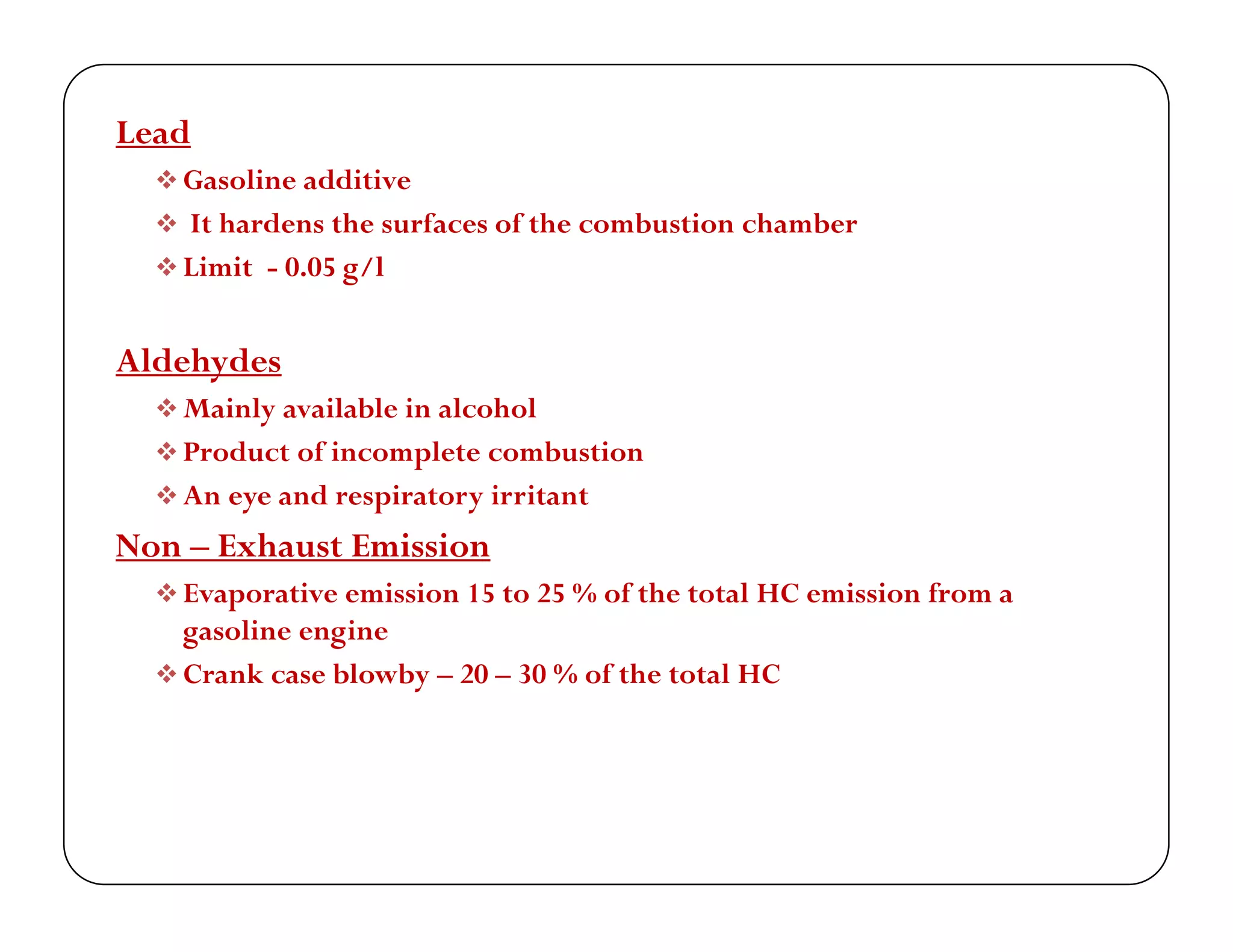

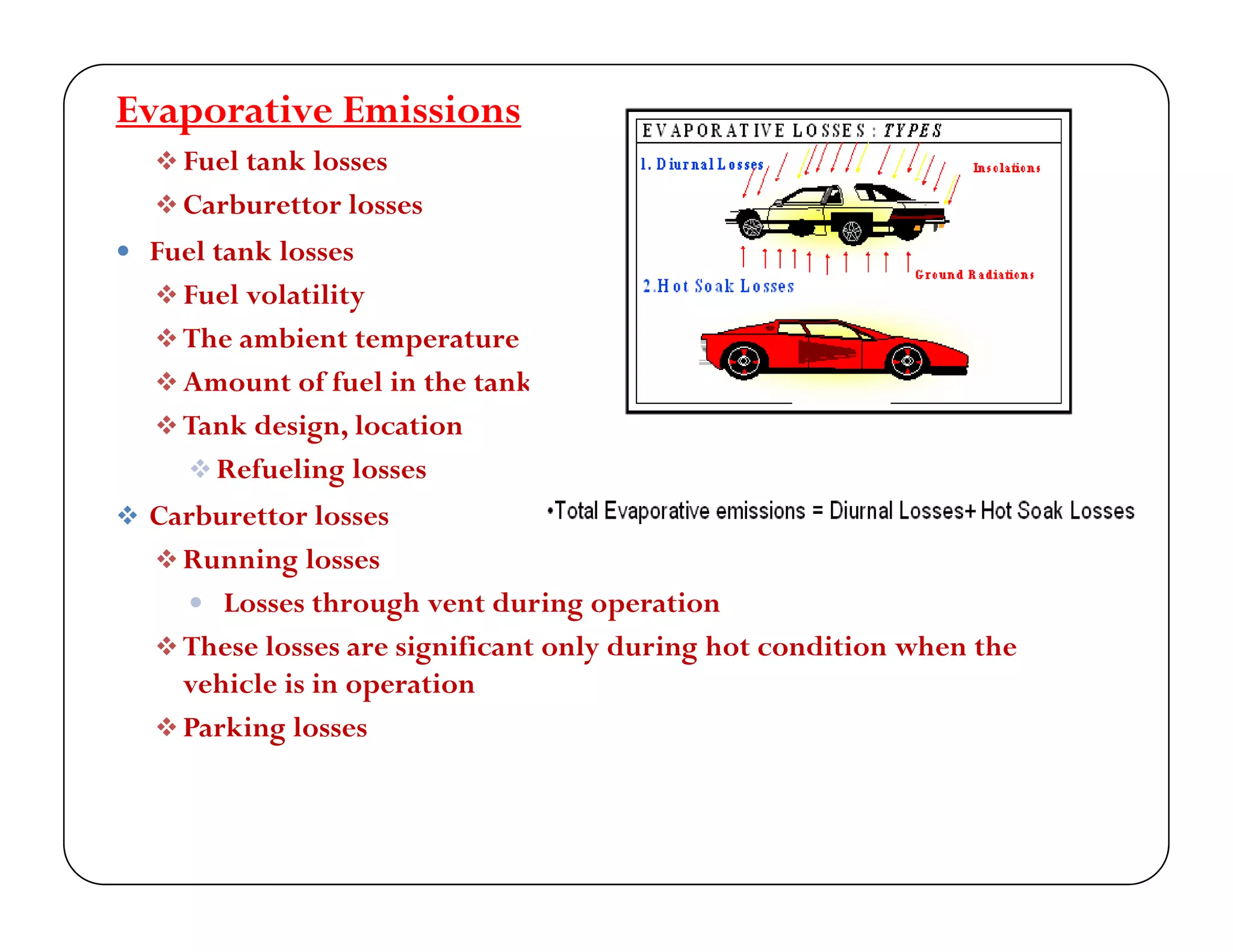

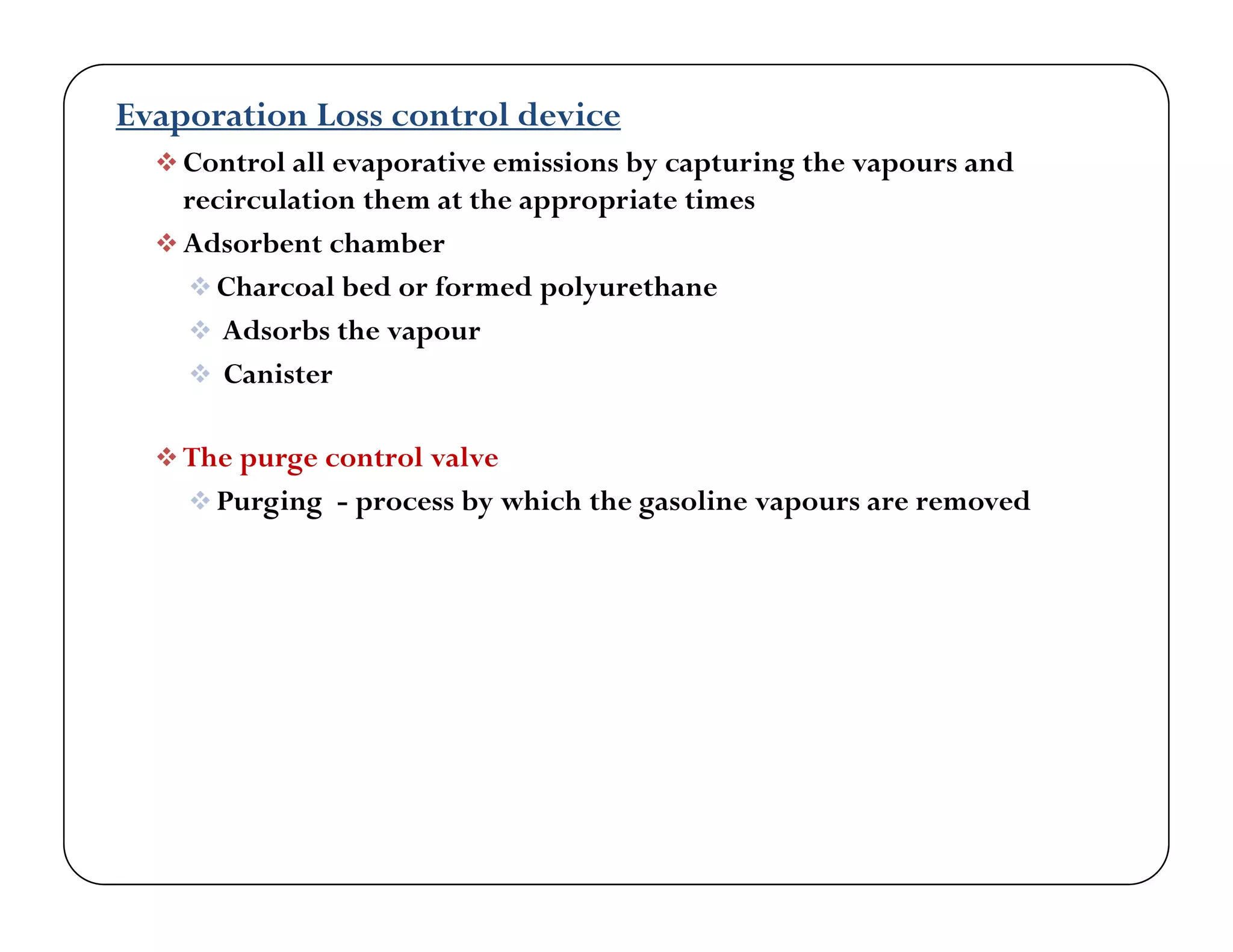

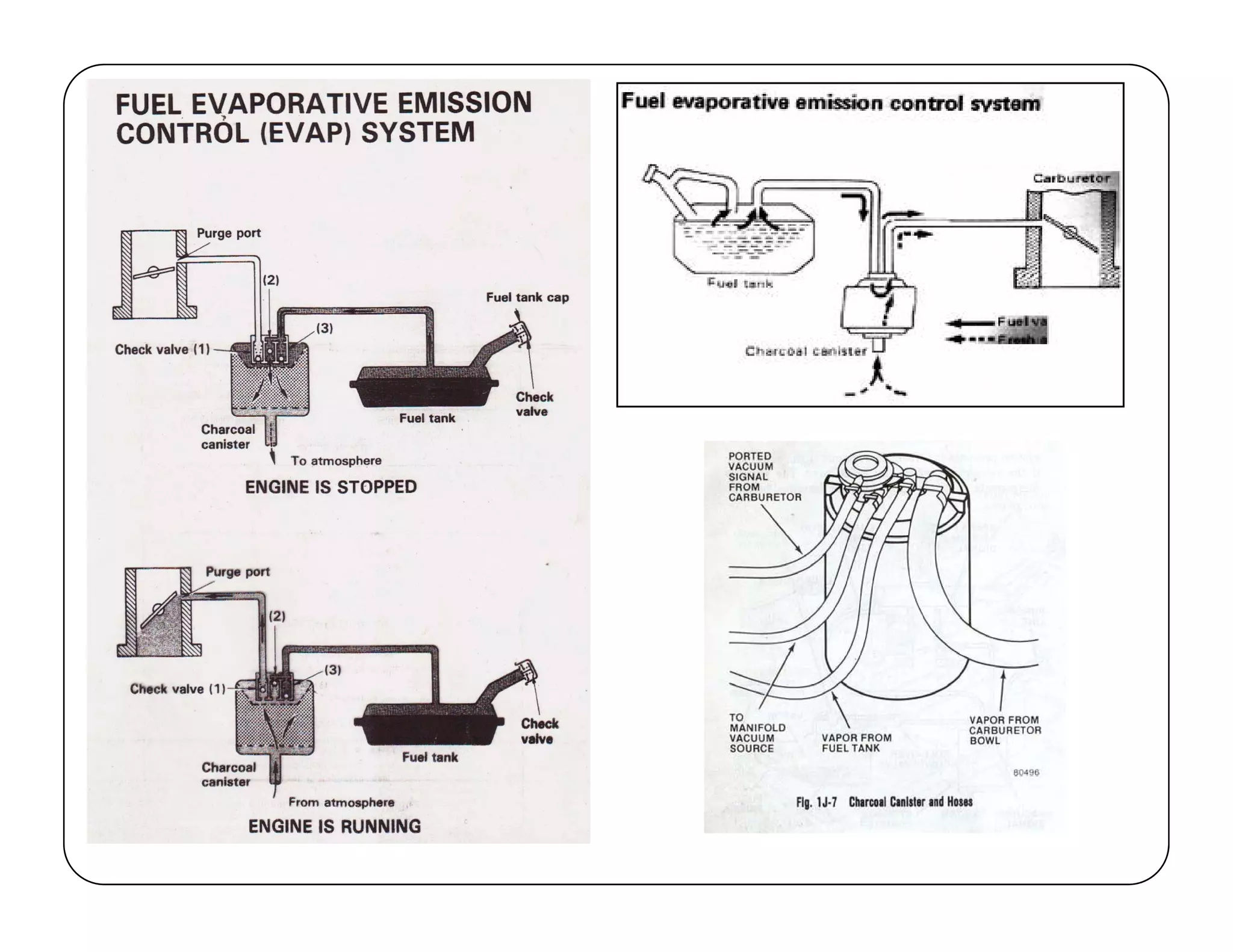

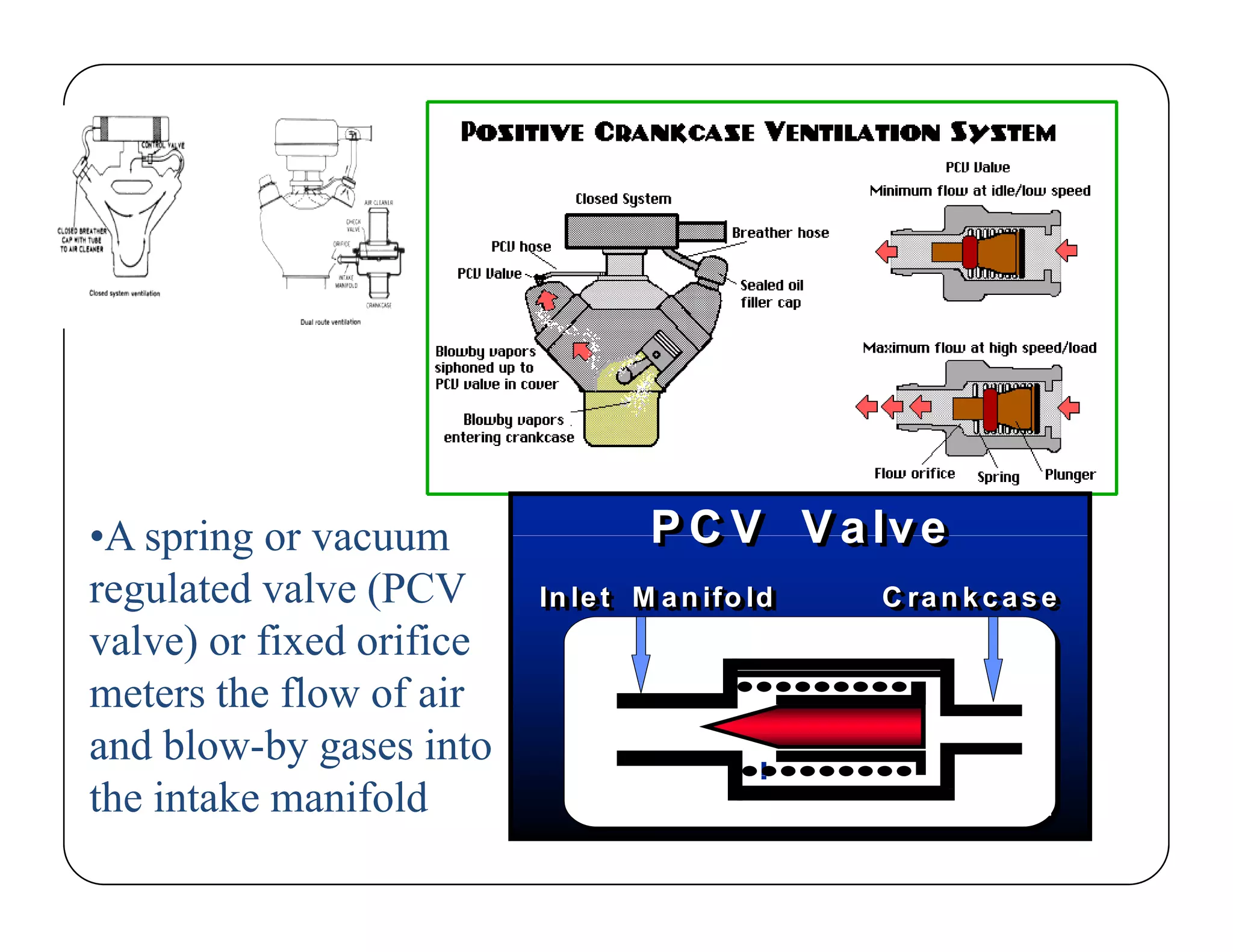

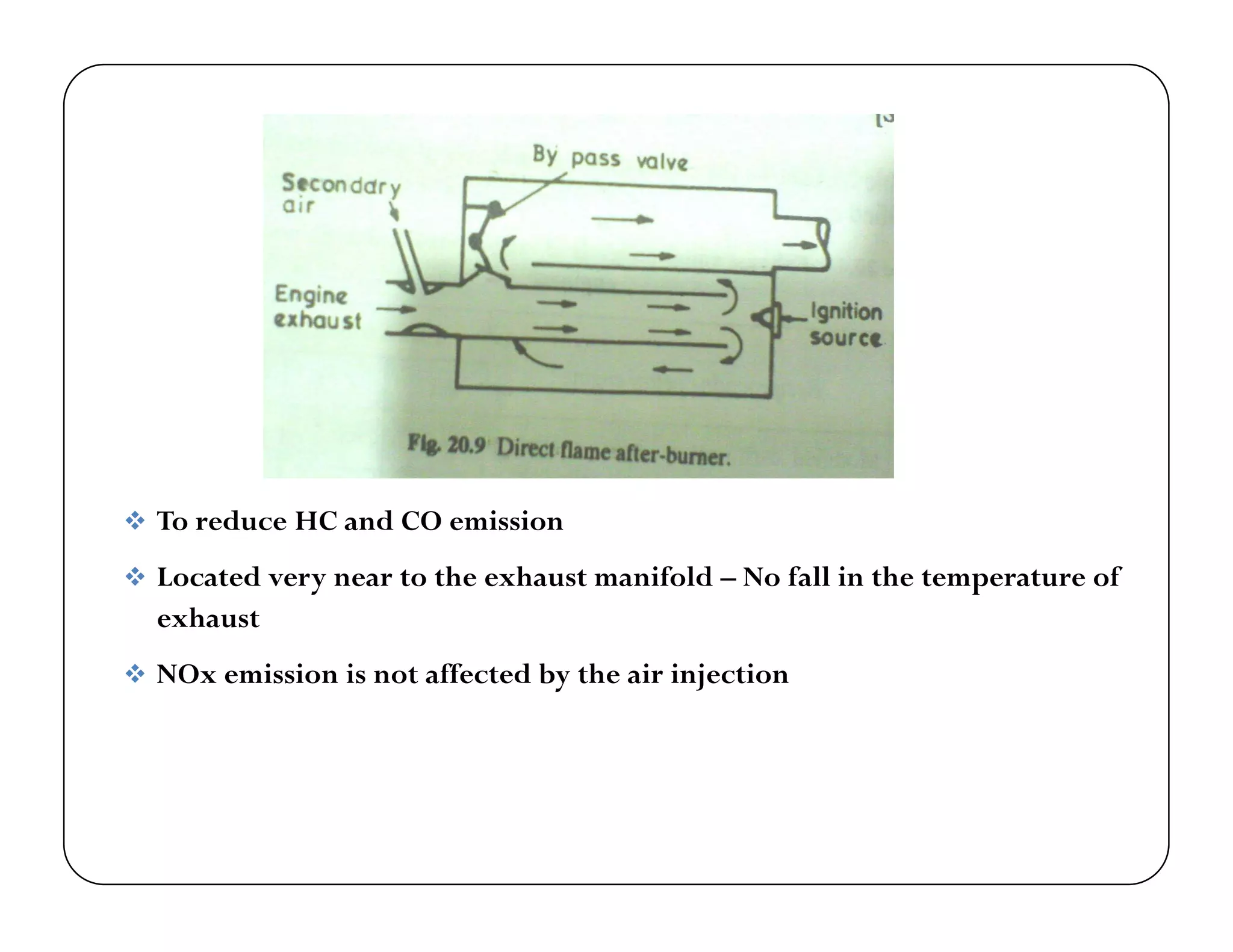

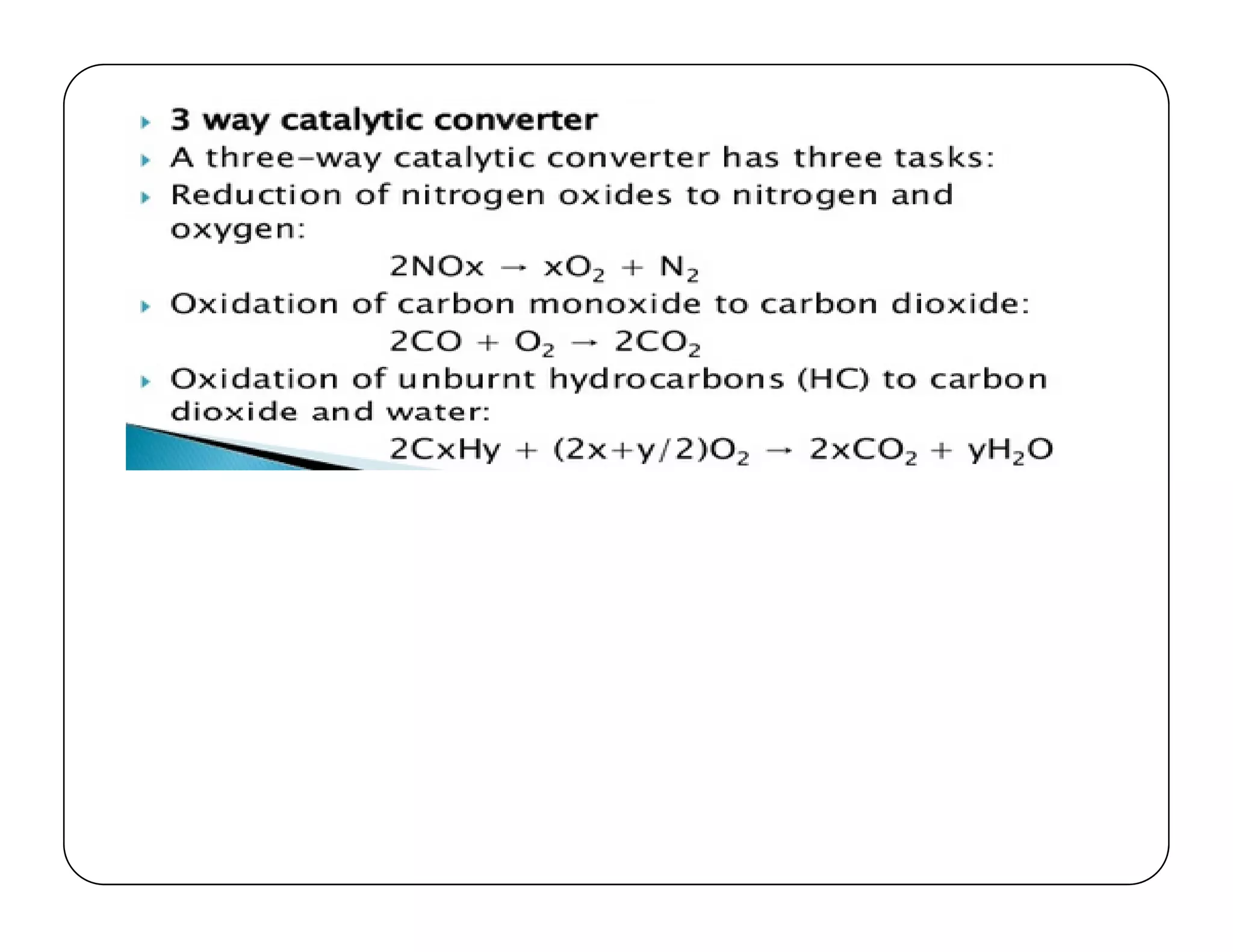

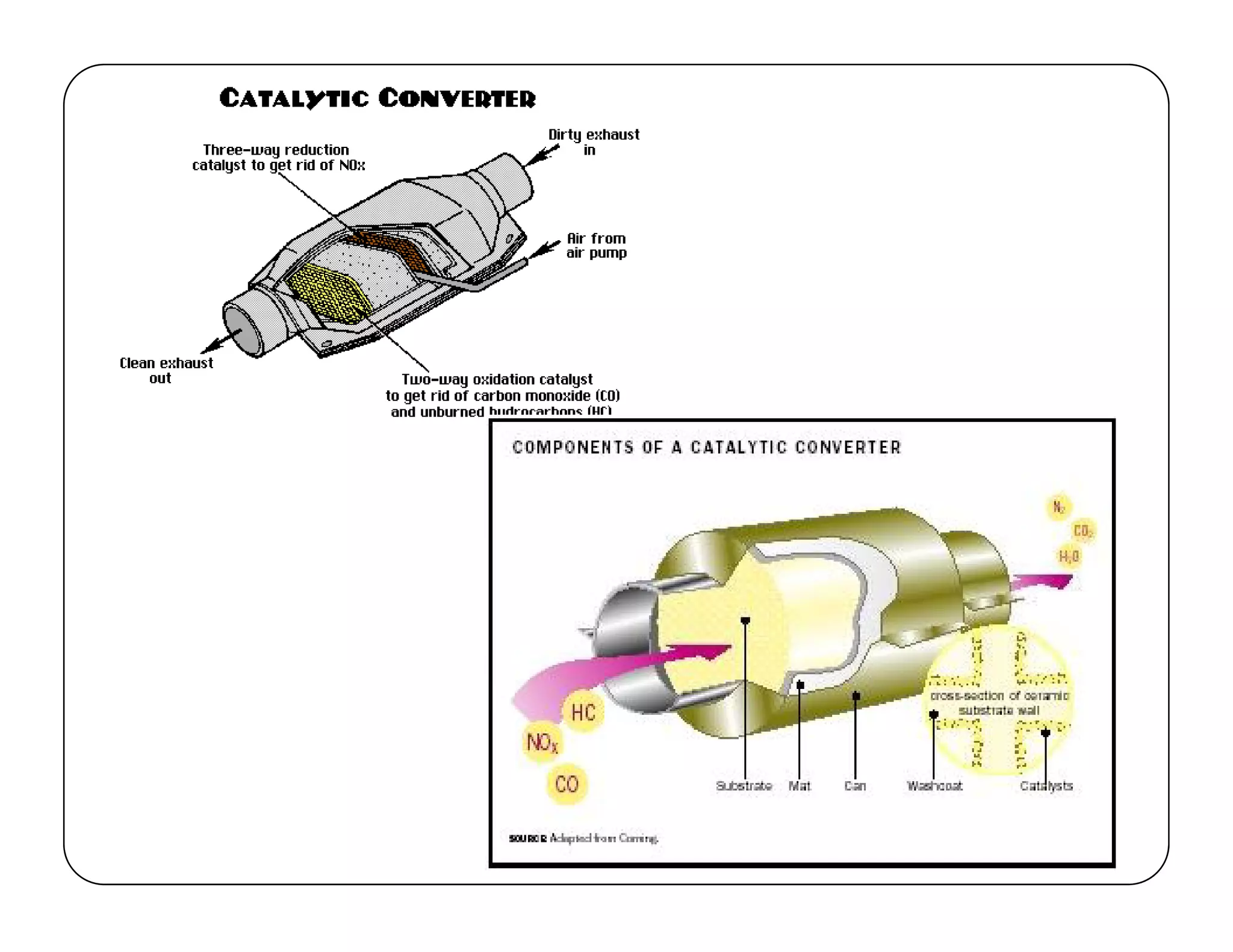

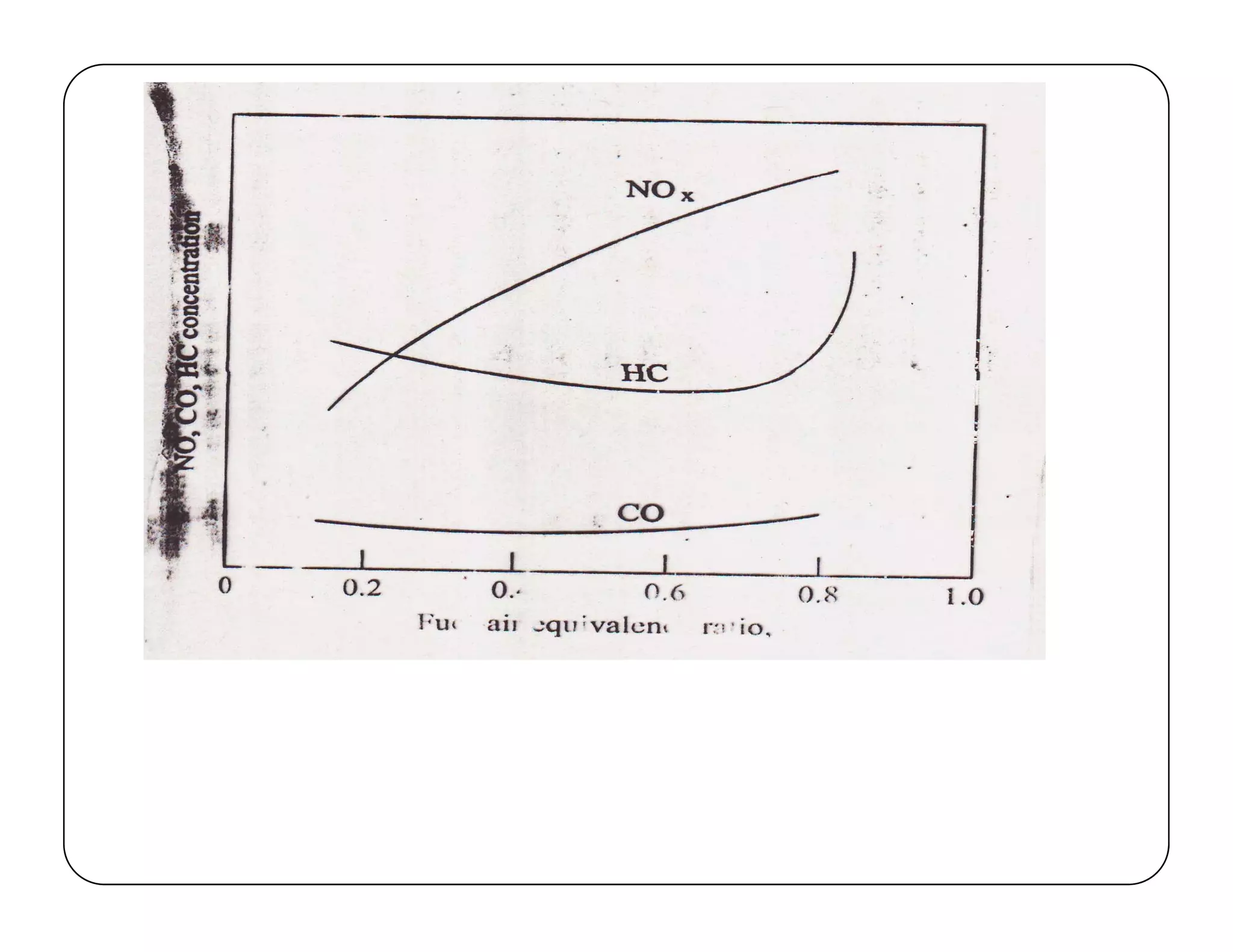

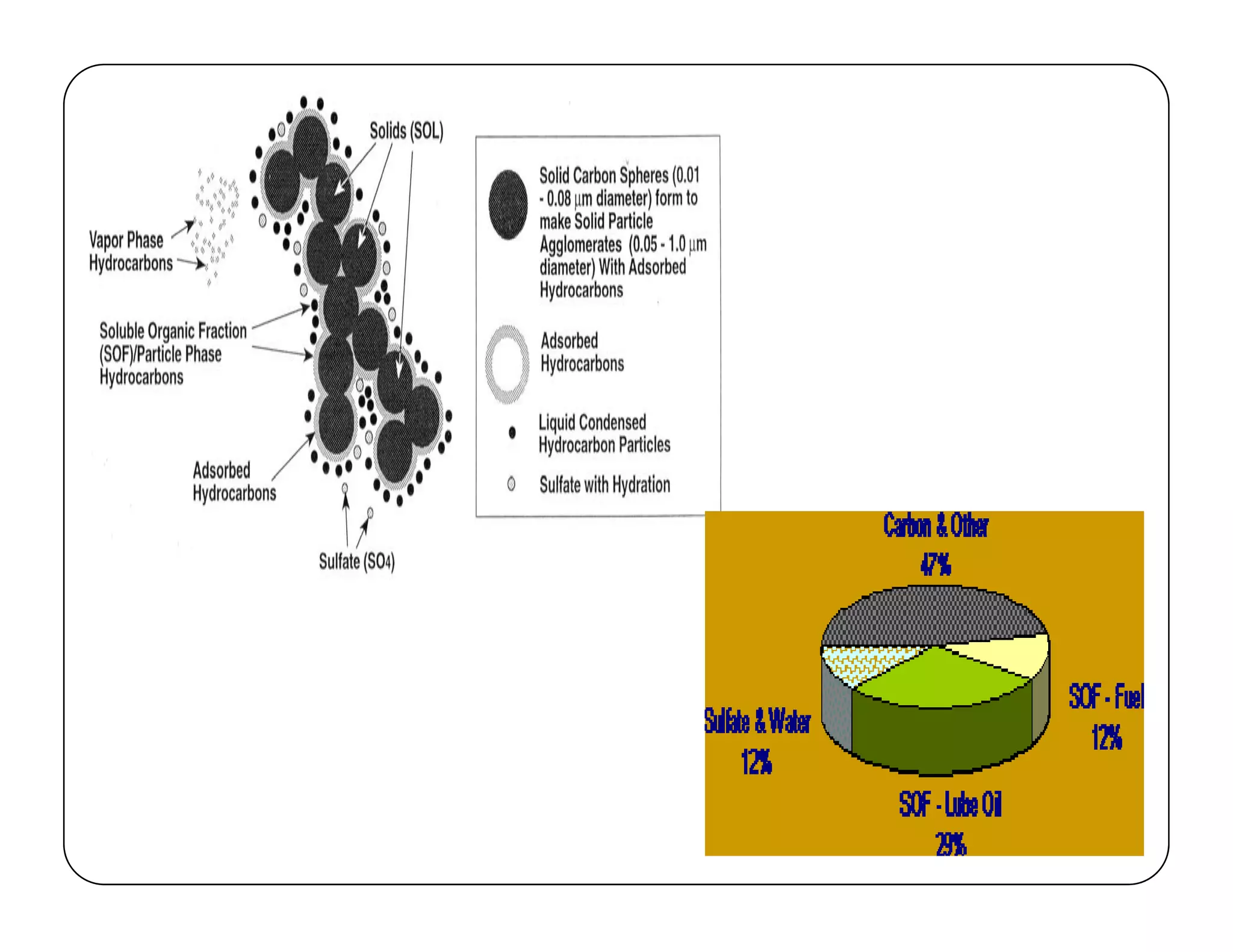

The document discusses engine emissions and their control. It describes the various pollutants emitted from internal combustion engines like hydrocarbons, carbon monoxide, nitrogen oxides, sulfur oxides and particulate matter. It explains the formation mechanisms of different pollutants and the factors affecting their production. The document also covers evaporative, crankcase and non-exhaust emissions from vehicles. It discusses various approaches to control emissions from spark ignition and compression ignition engines like modifying engine design, operating parameters, using emission treatment devices and reformulating fuels.

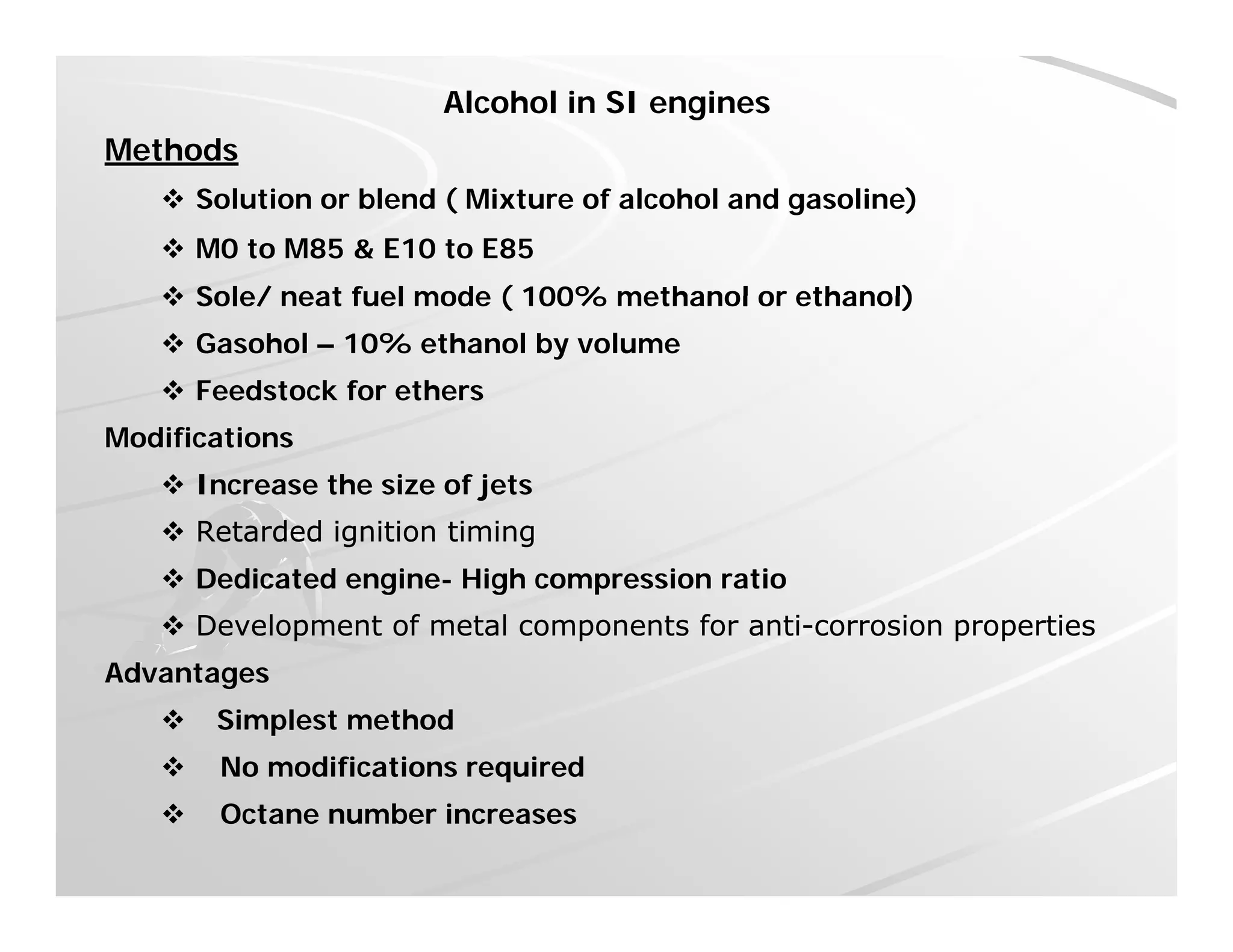

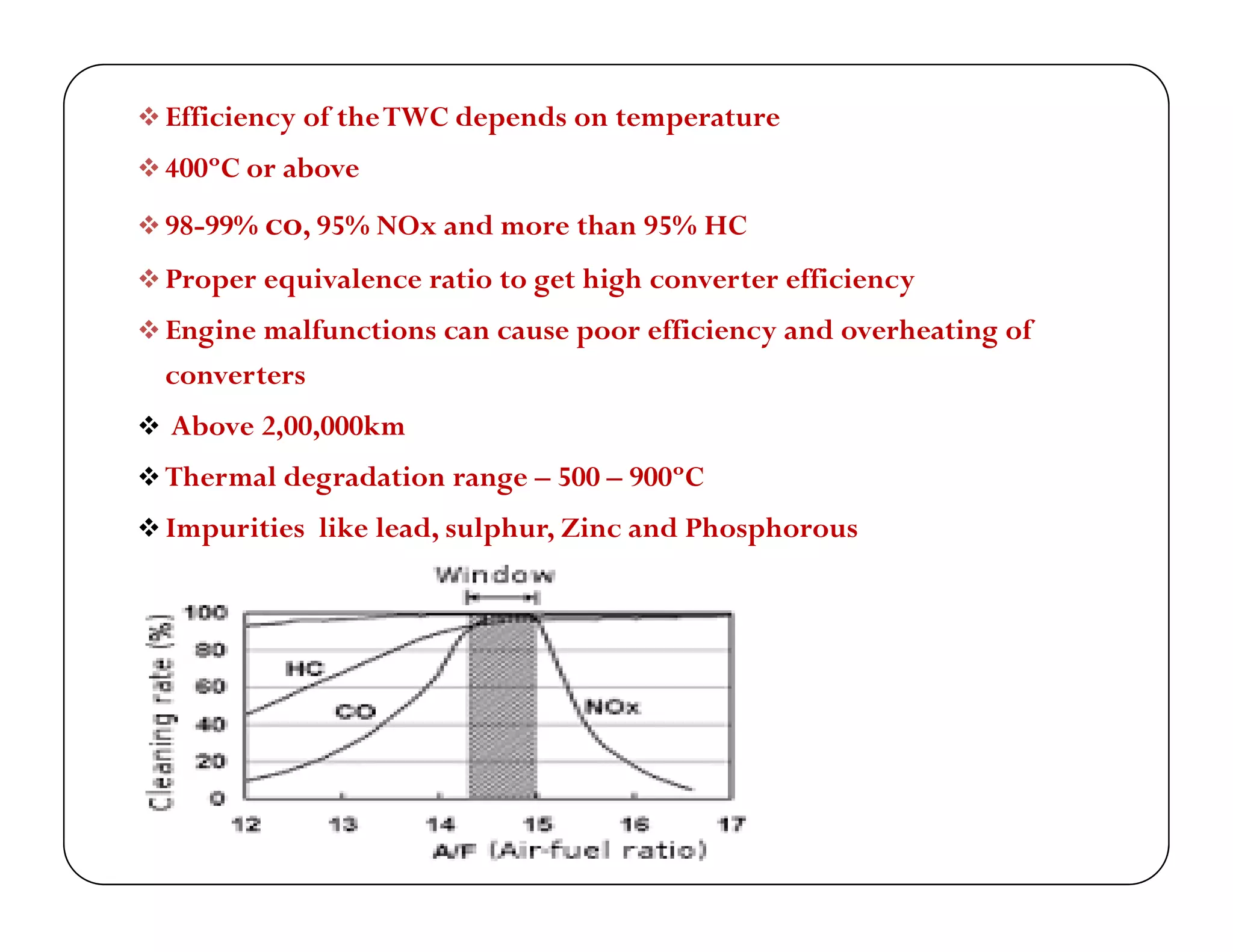

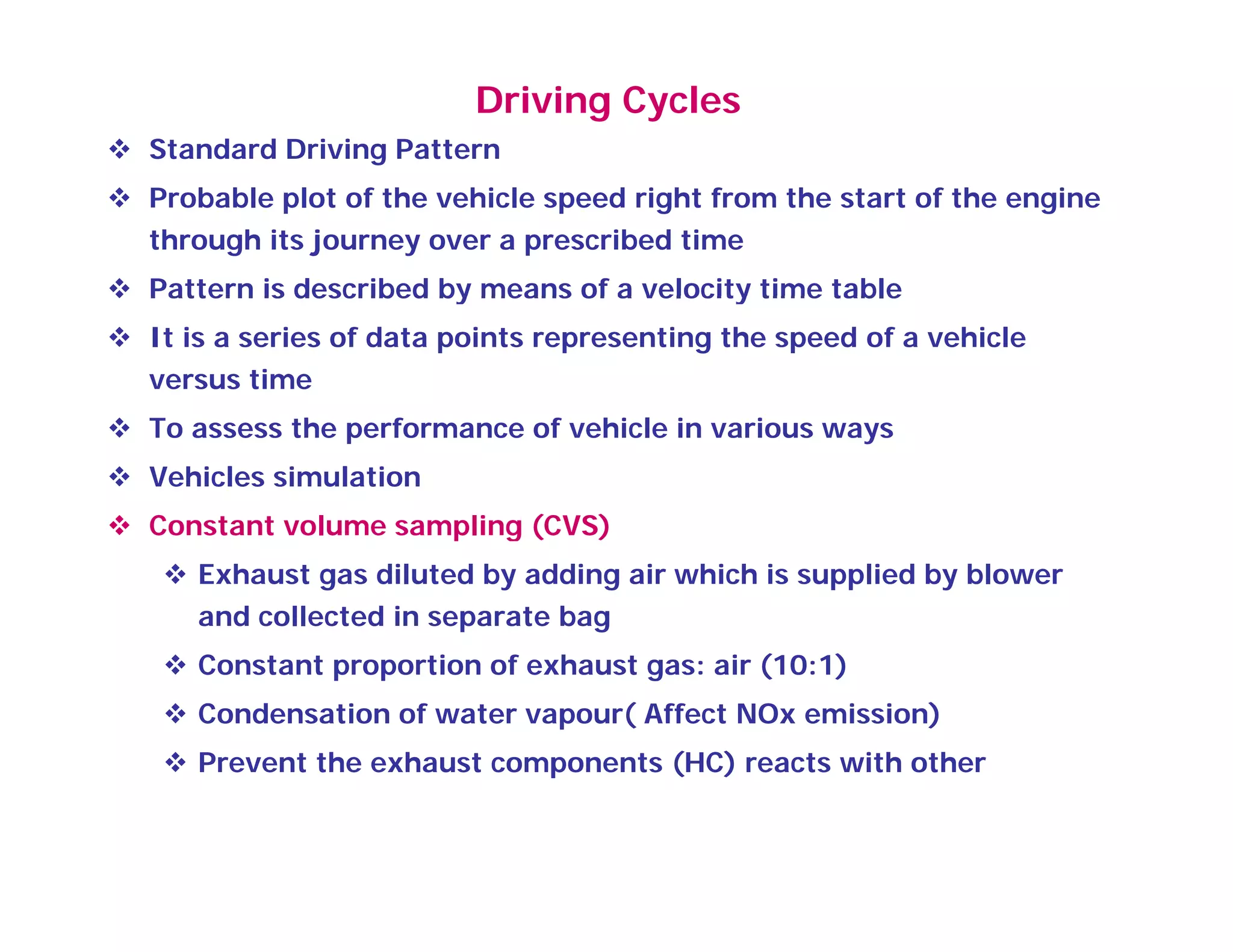

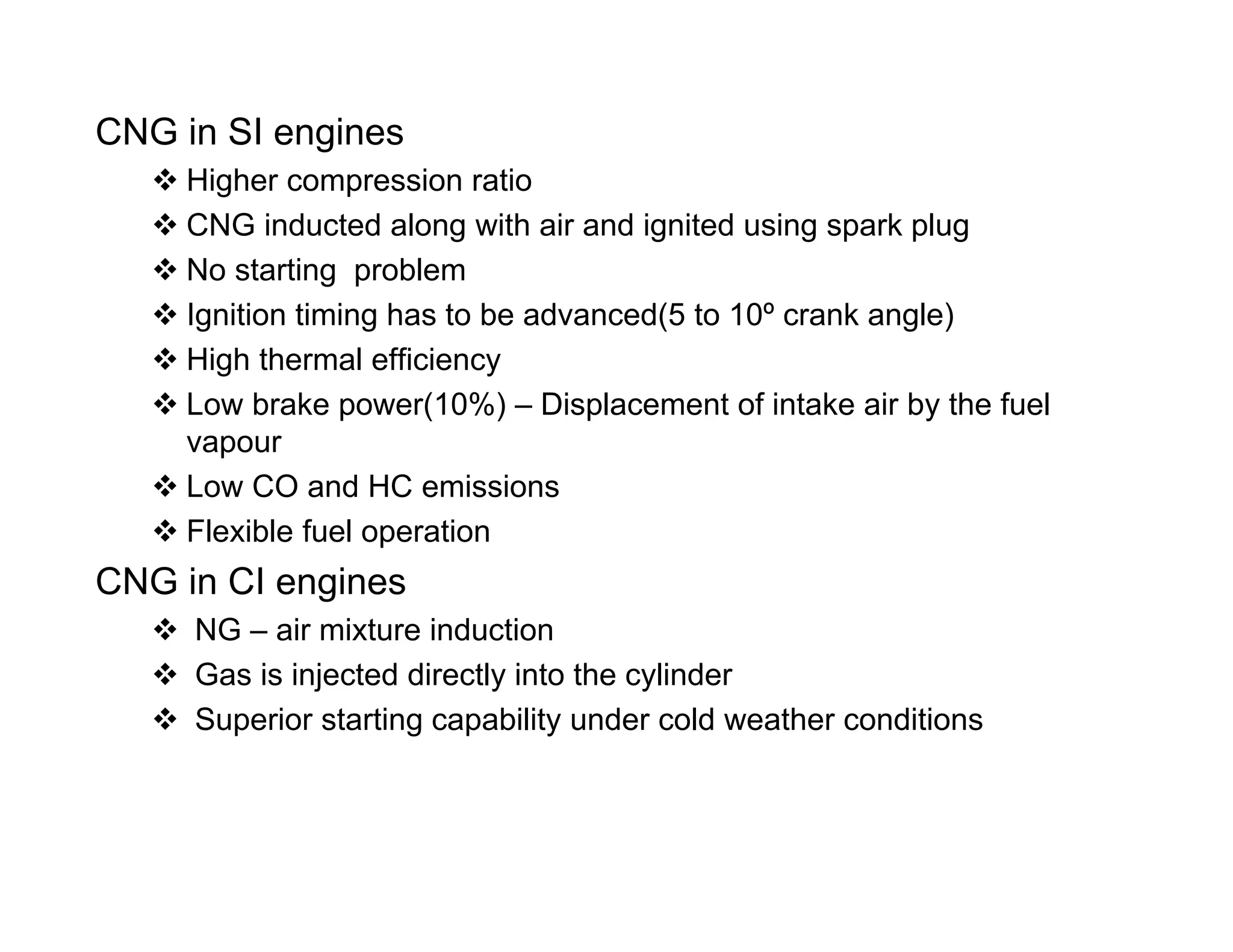

![Typical Driving Cycle

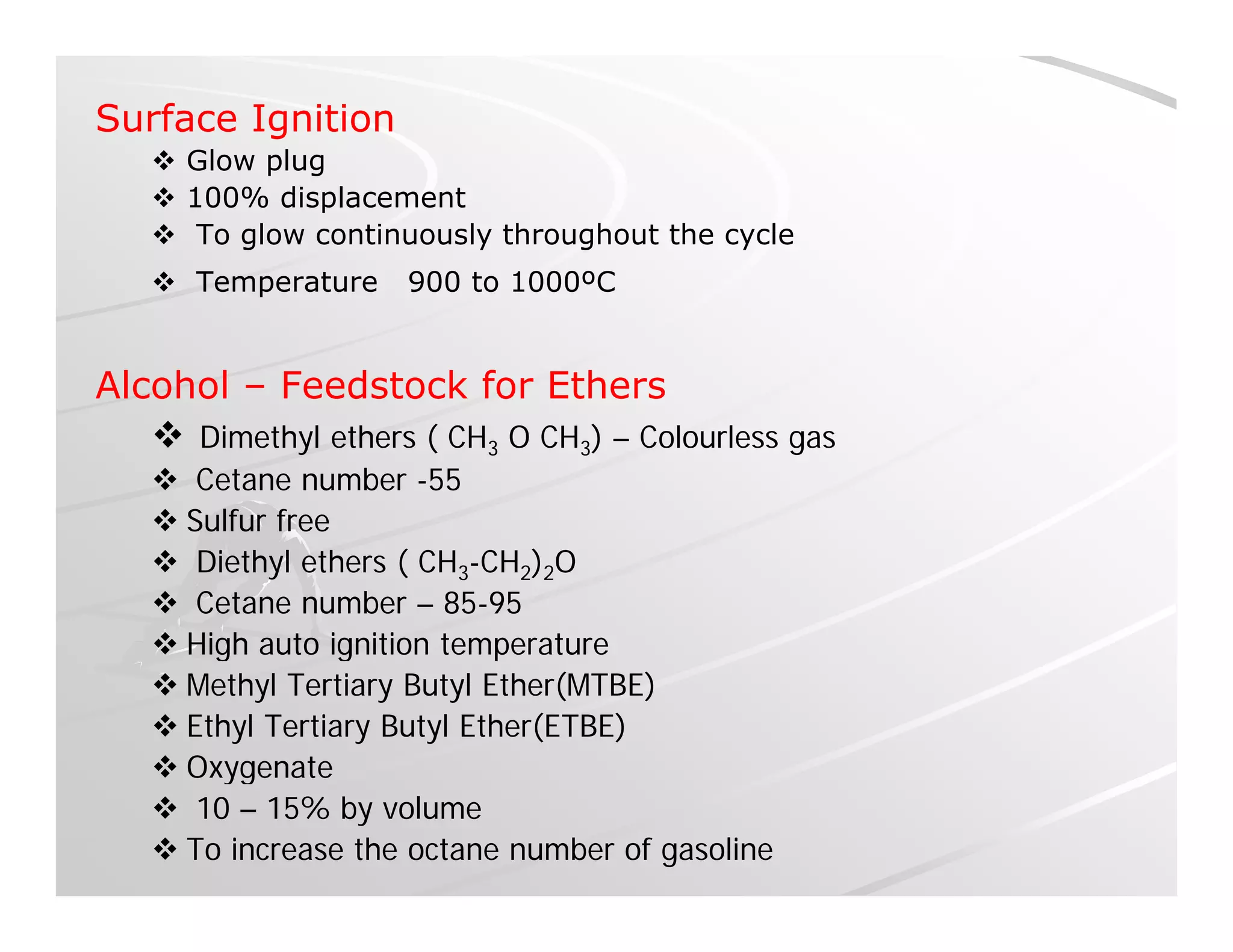

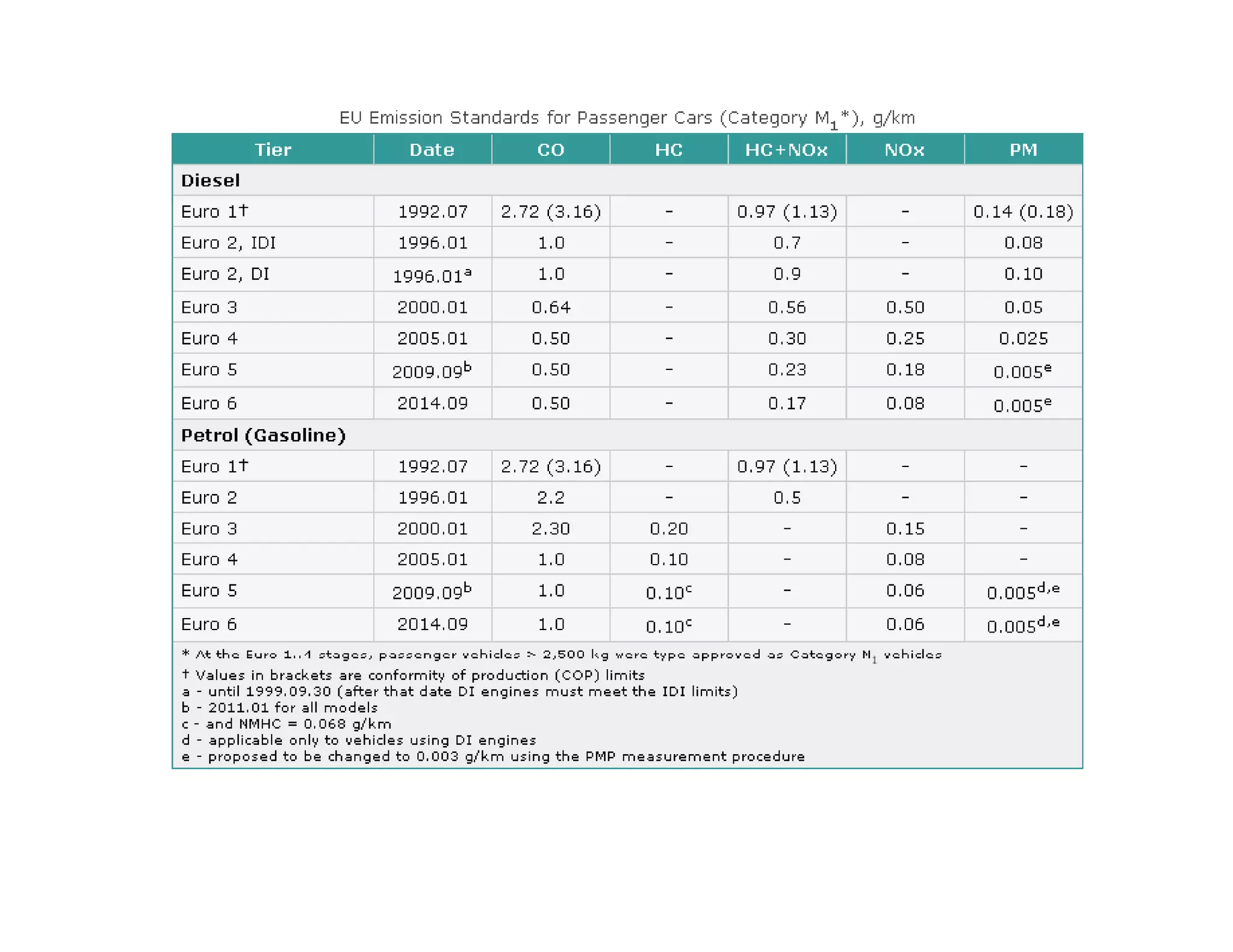

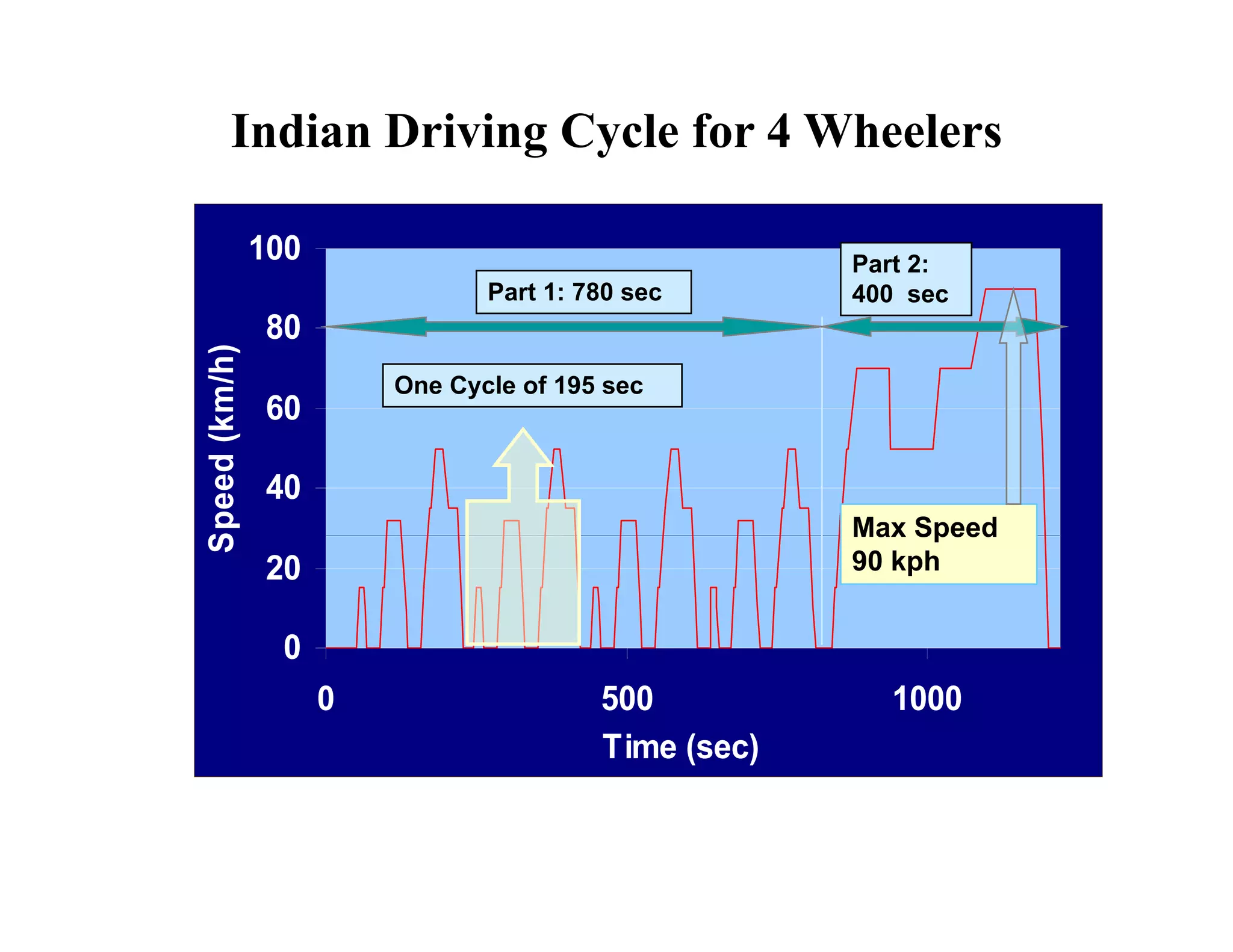

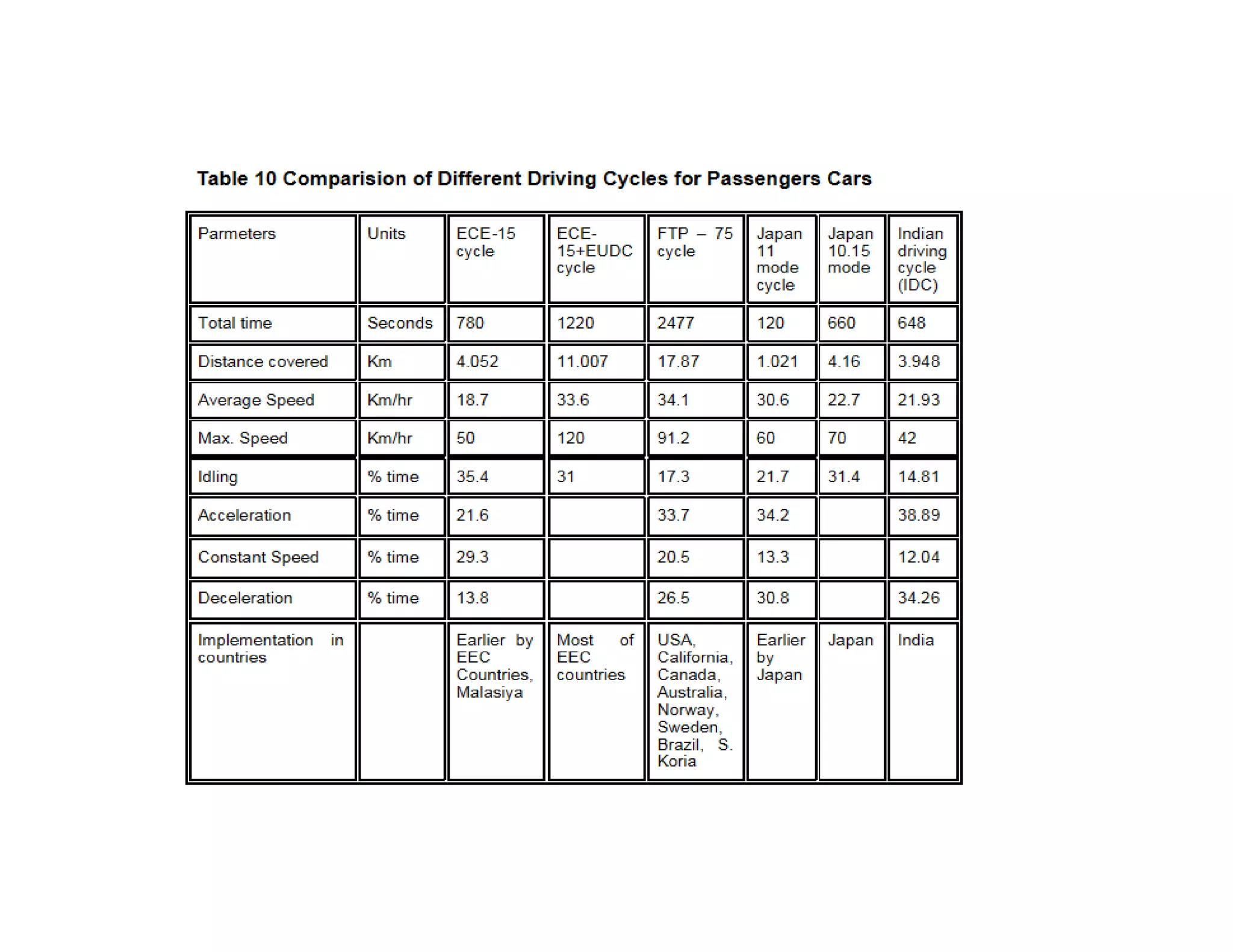

EMISSION CYCLE

130

100

110

120

130

60

70

80

90

EED[KMPH]

30

40

50

60

SPEE

0

10

20

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

SECONDSSECONDS

EURO II BS II](https://image.slidesharecdn.com/engineemissionandtheircontrol-160403142310/75/Engine-emission-and-their-control-74-2048.jpg)

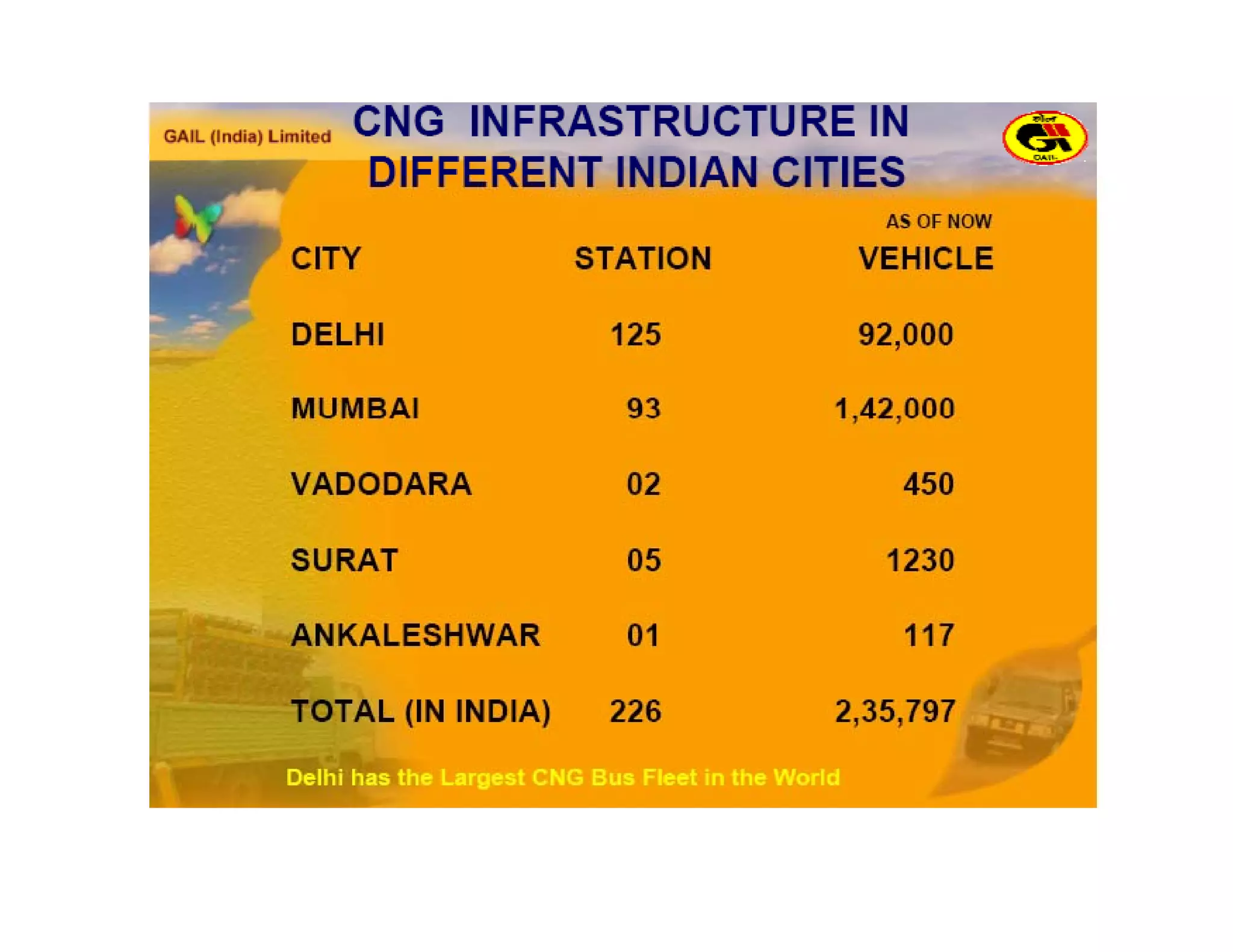

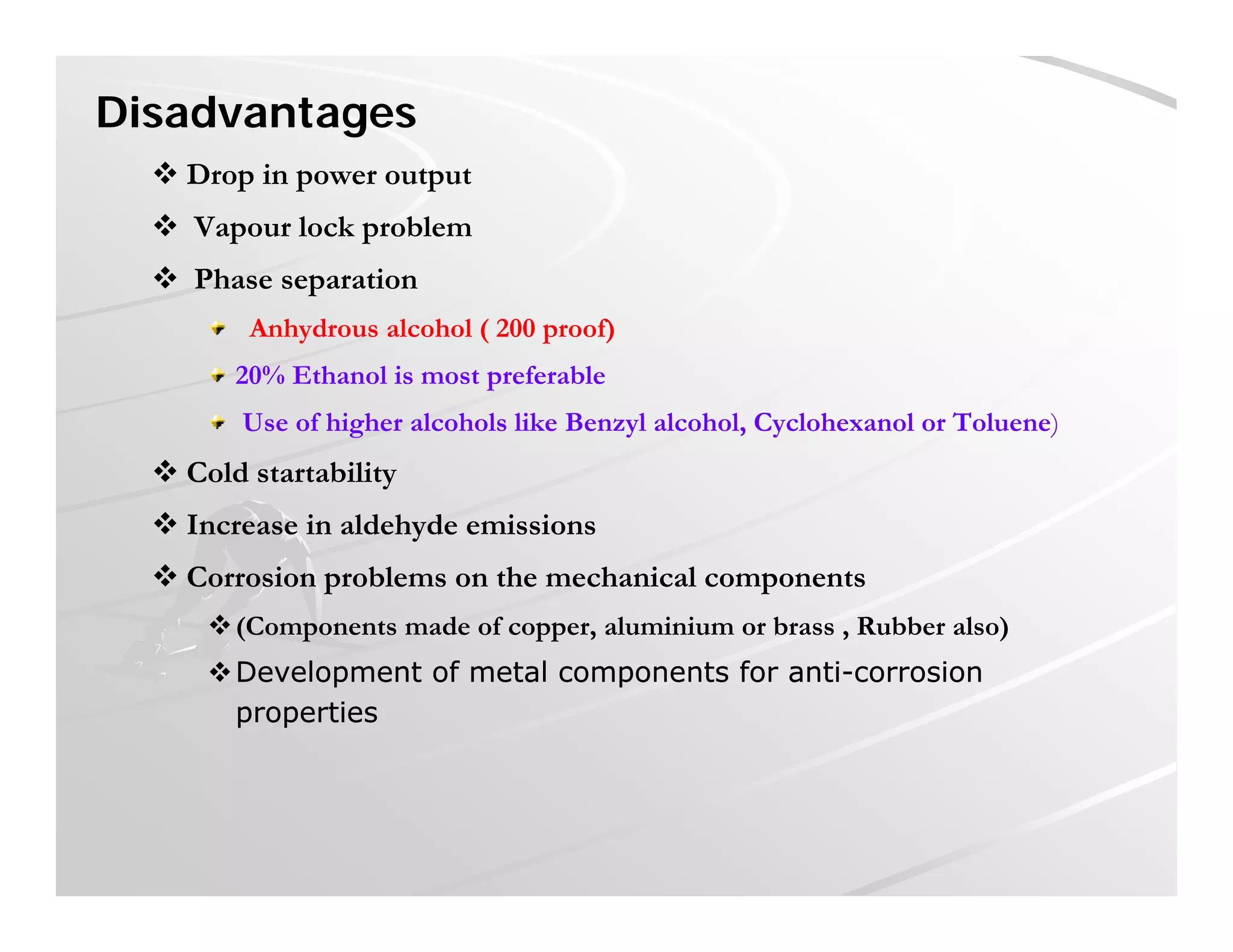

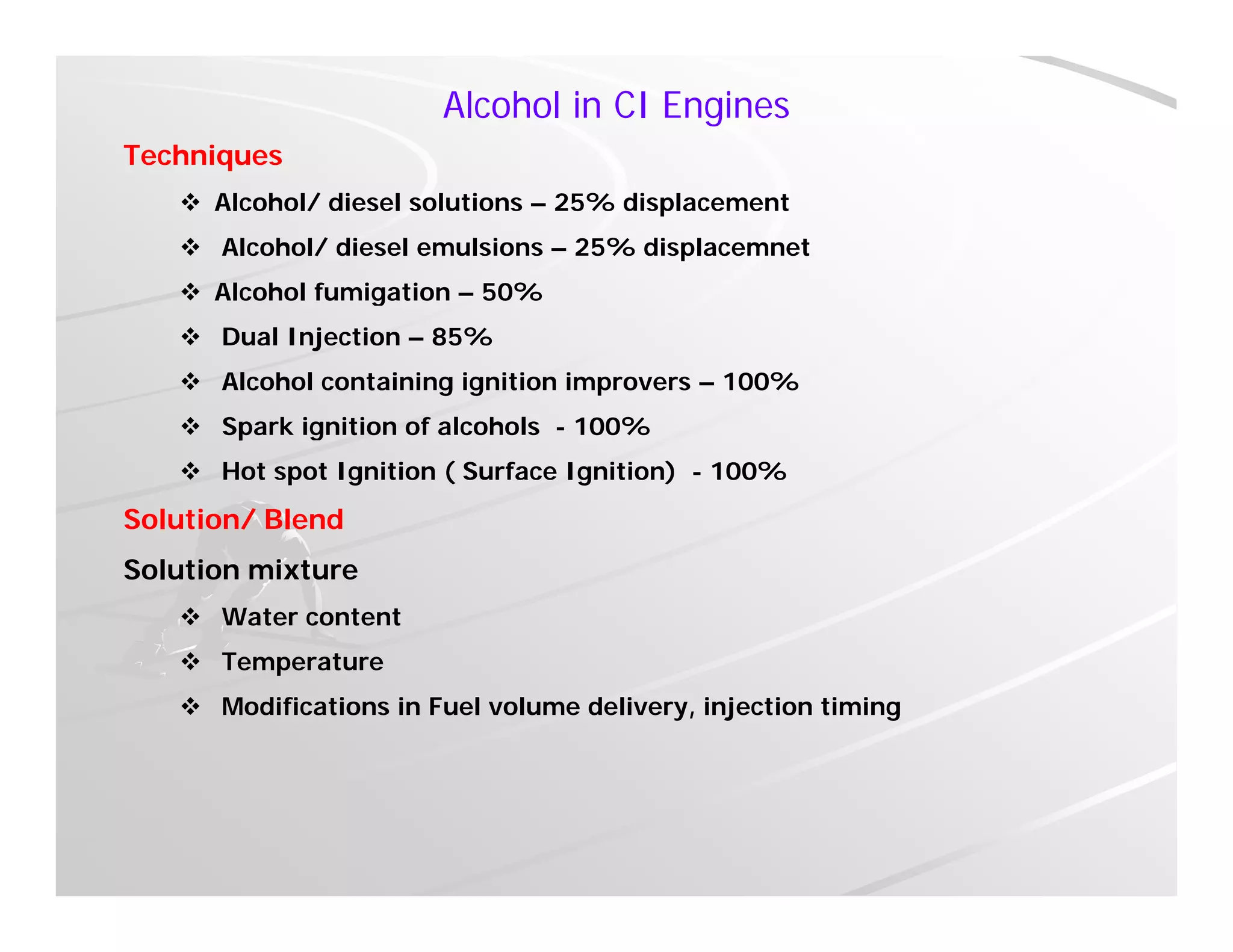

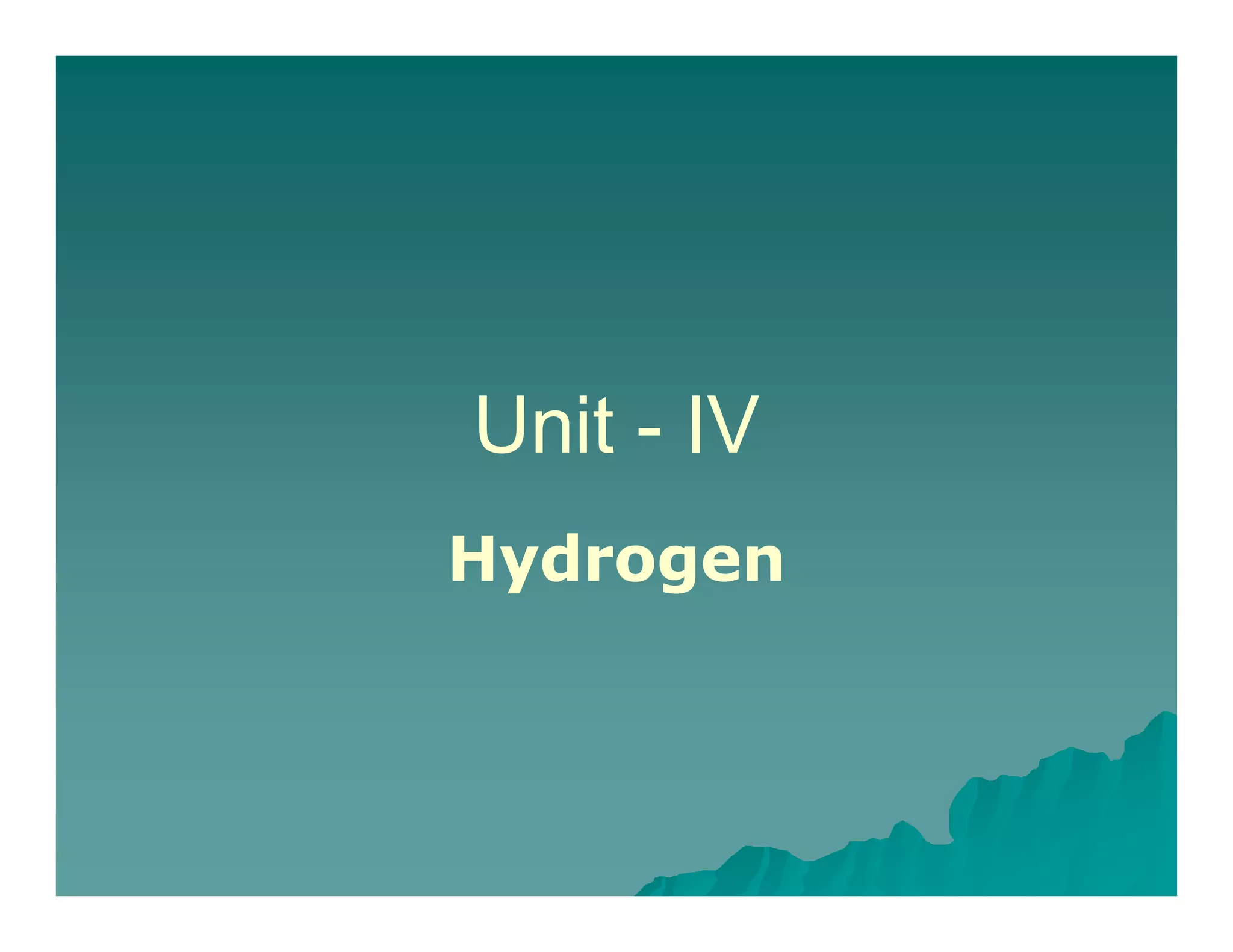

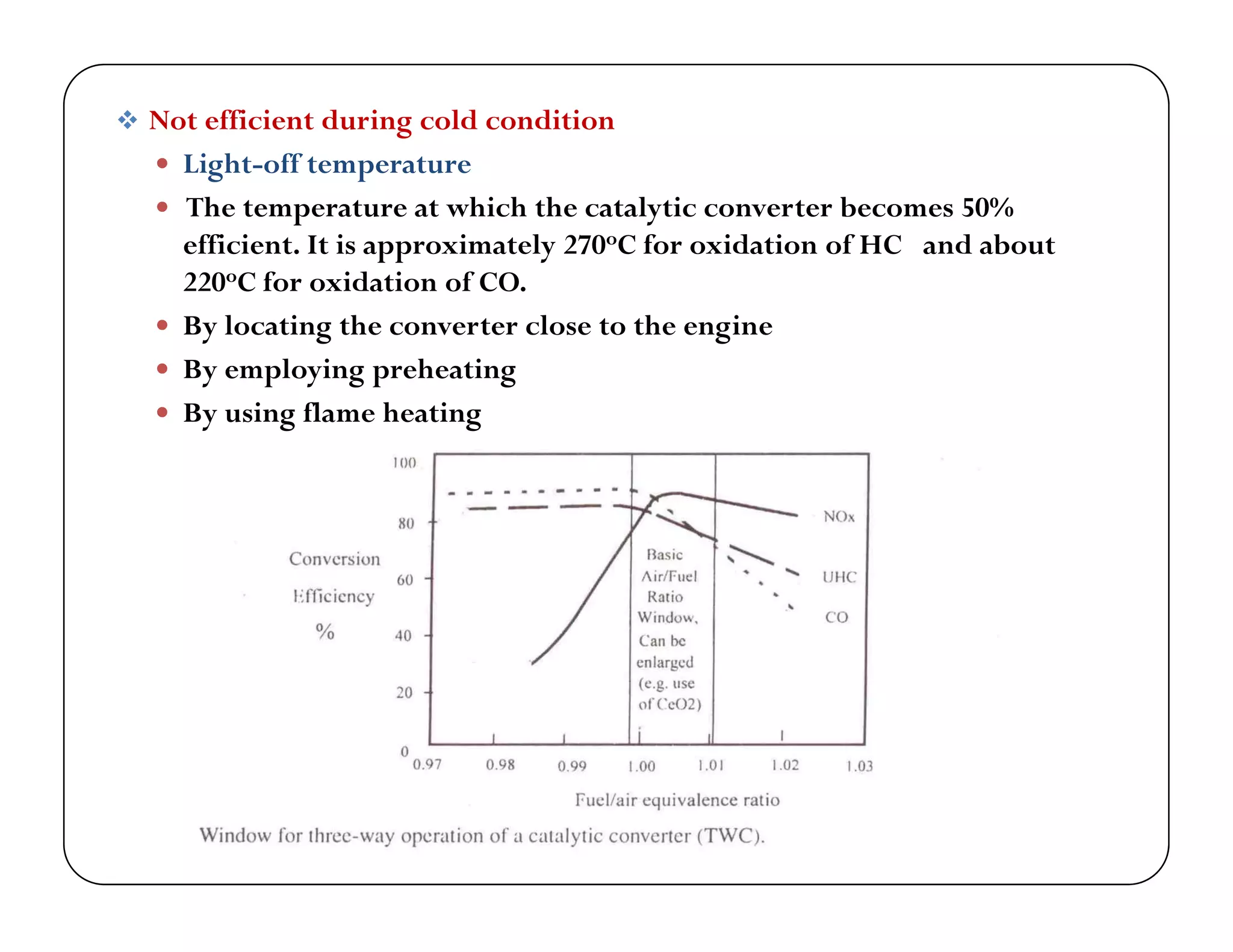

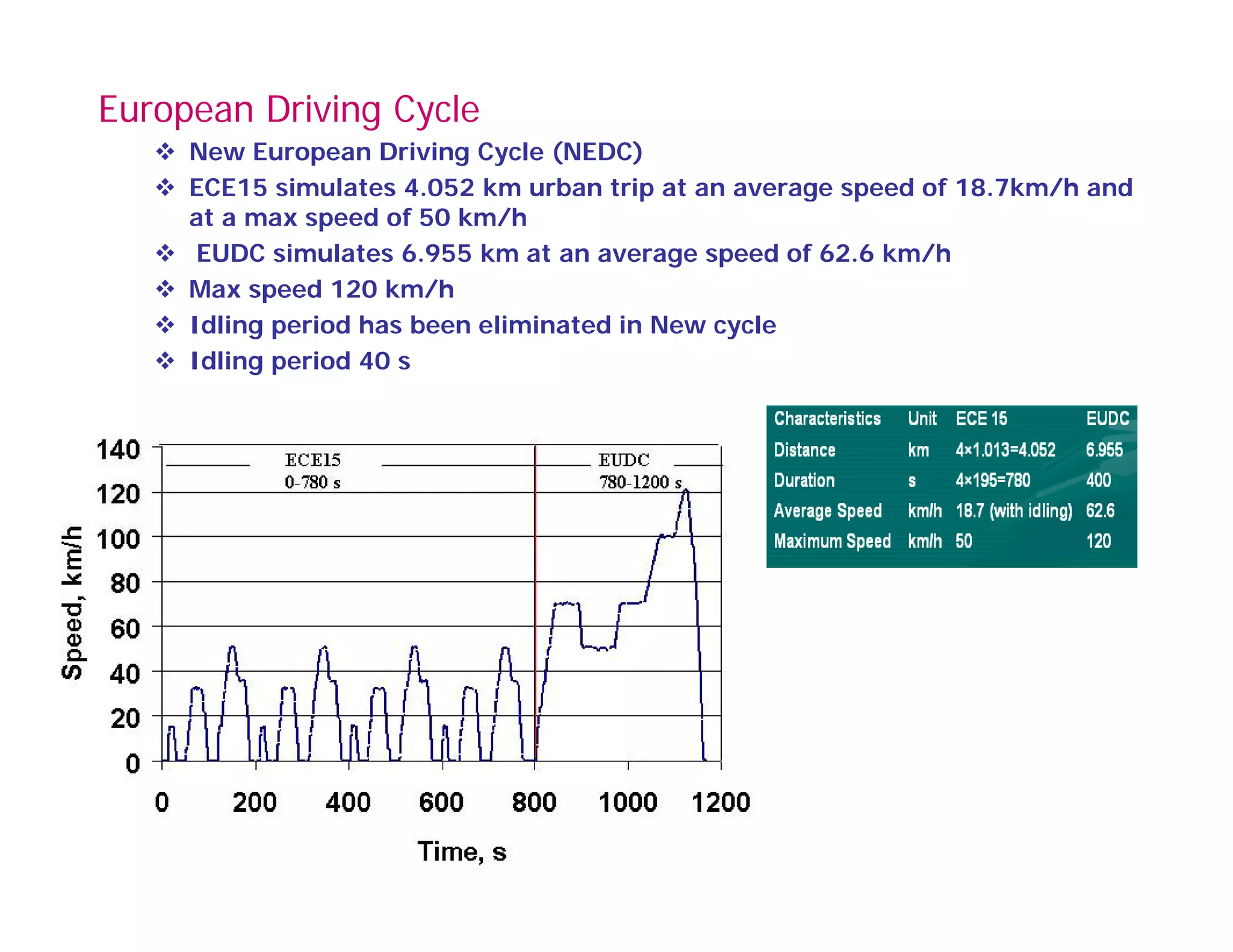

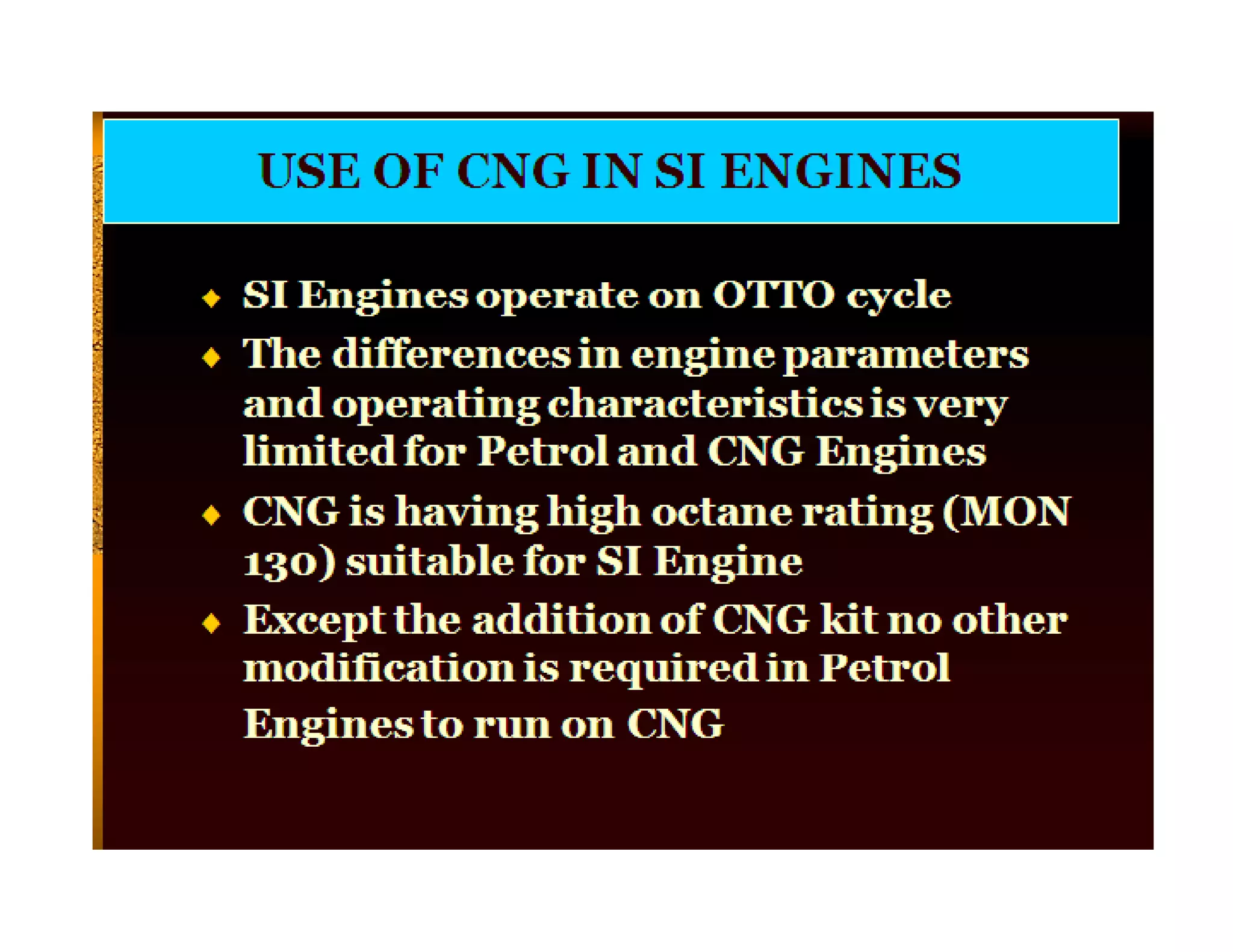

![Fuels Characteristics

Natural Gas Diesel Oil

Carbon content [mass %] 73,3 85,9

Hydrogen content [mass %] 23,9 14,0

Oxygen content [mass %] 0,4 0,05

Carbon-to-hydrogen ratio 0 25 - 0 33 0 16Carbon to hydrogen ratio 0,25 0.33 0,16

Relative molar mass 17 - 20 ~170

Density at 0 oC and 1,013 bar [kg/m3] ~0,83 840

B ili t t [°C / 1 b ] 162 f 170 t 380Boiling temperature [°C / 1 bar] -162 from 170 to 380

Autoignition temperature [°C] 540 - 560 320 – 330

Octane number 120 -130 -

Cetane number - 52 - 56

Methane number 69 - 99 -](https://image.slidesharecdn.com/engineemissionandtheircontrol-160403142310/75/Engine-emission-and-their-control-134-2048.jpg)

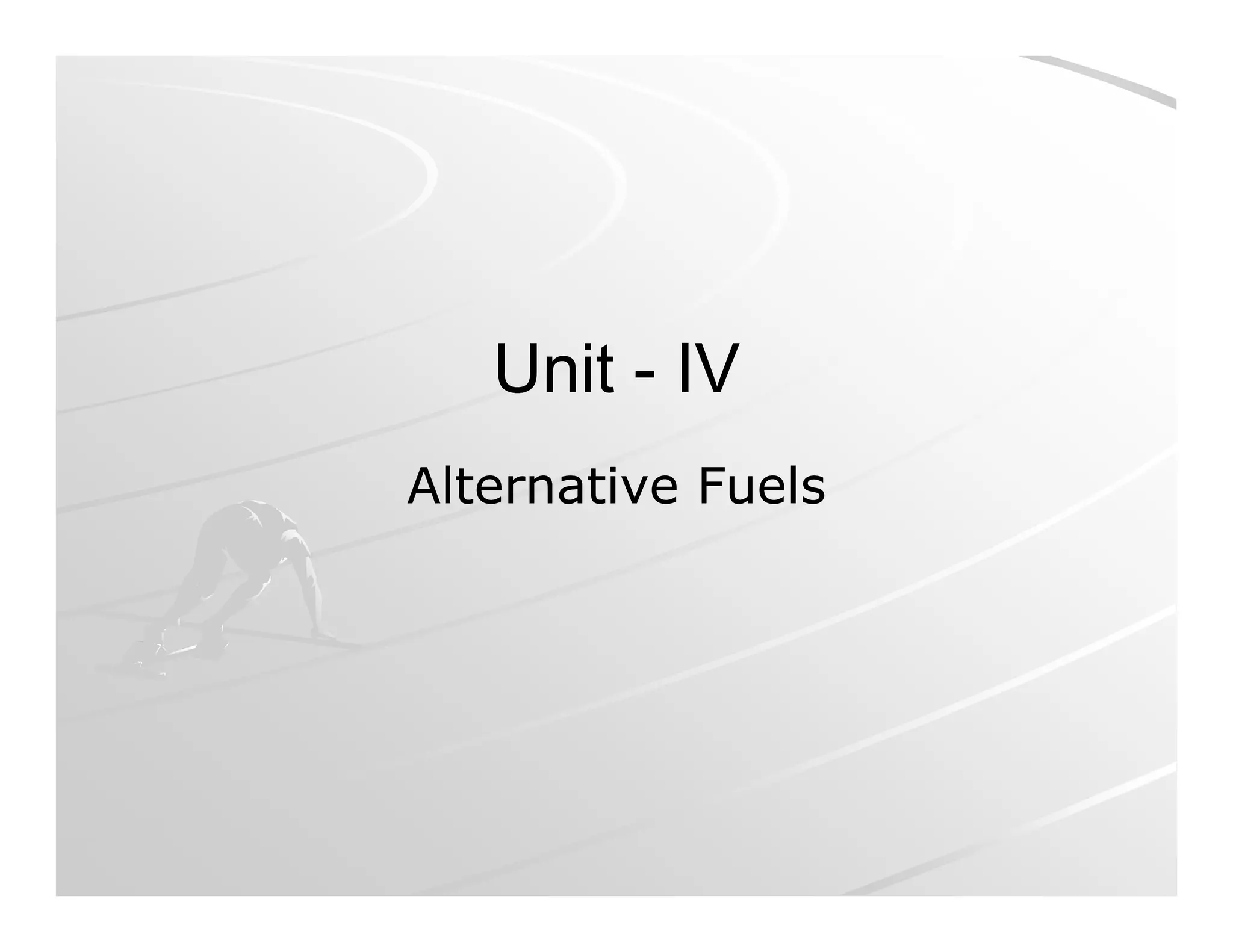

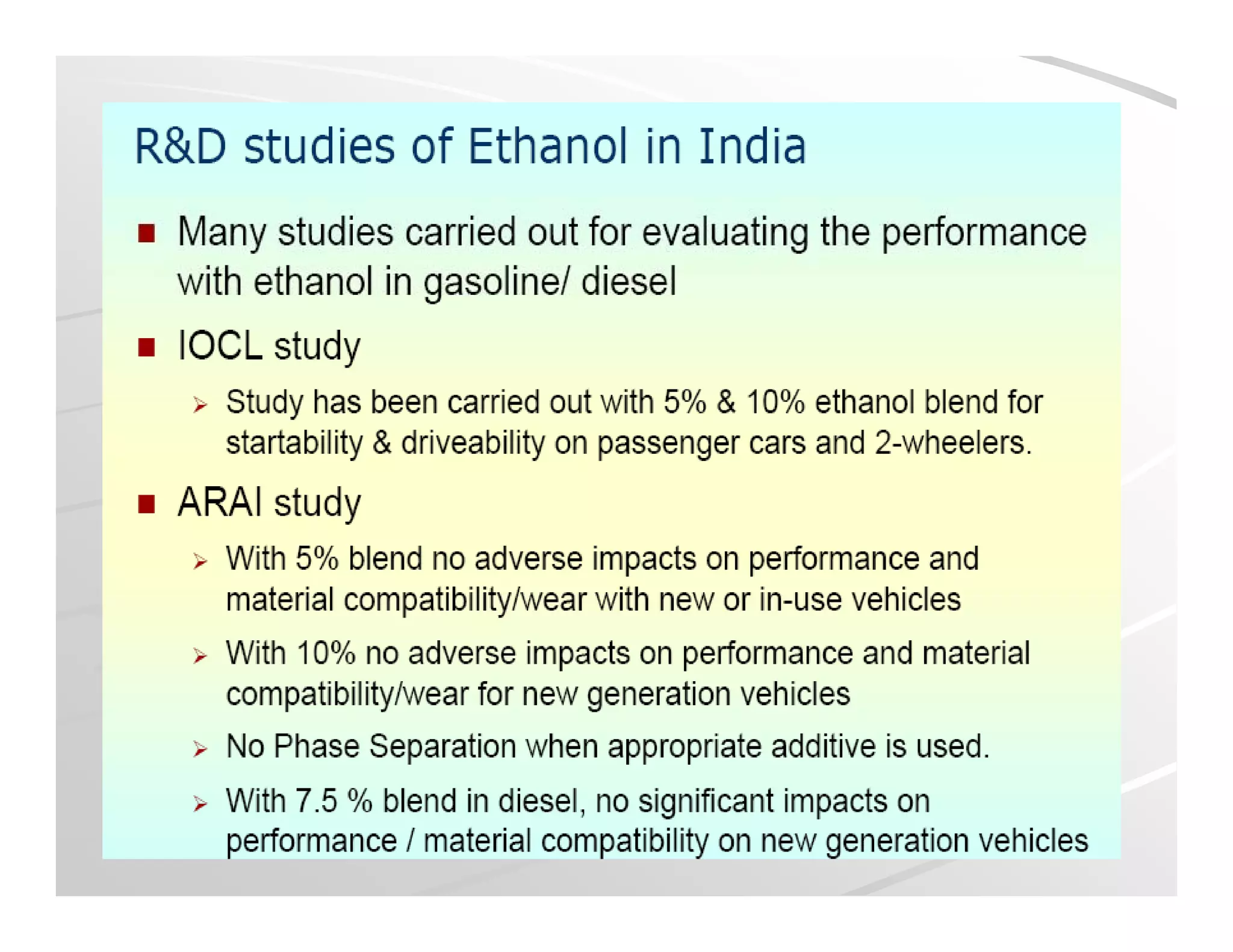

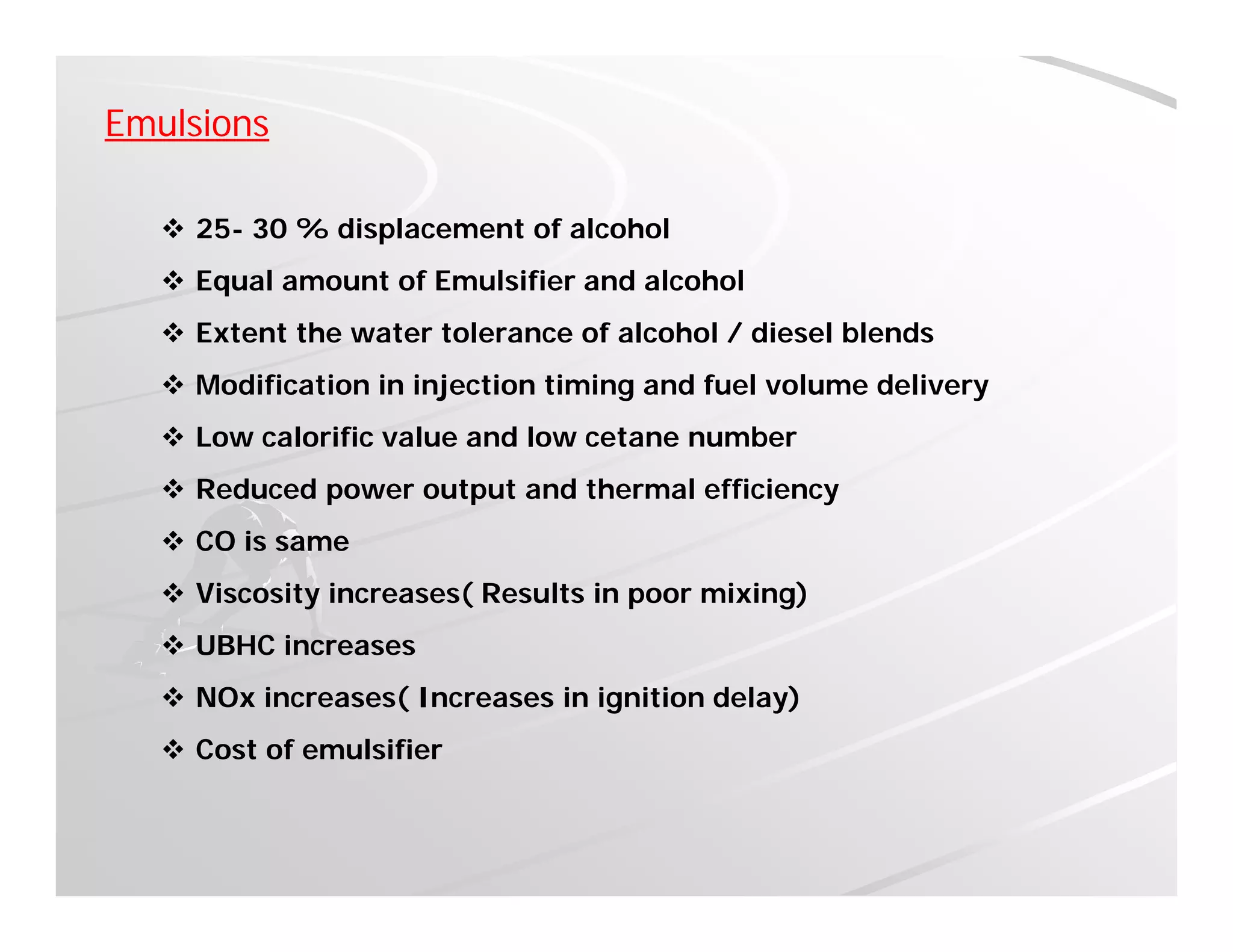

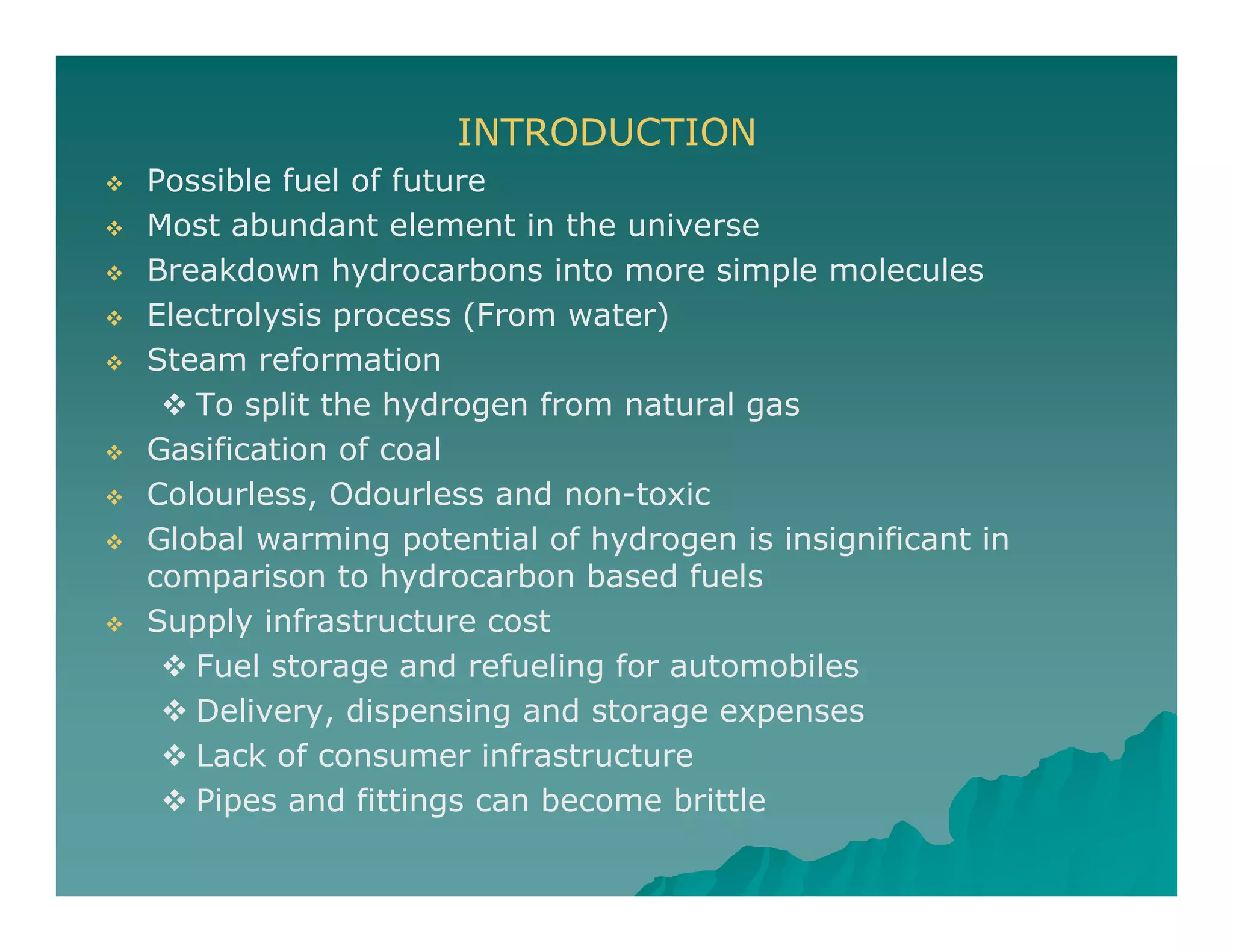

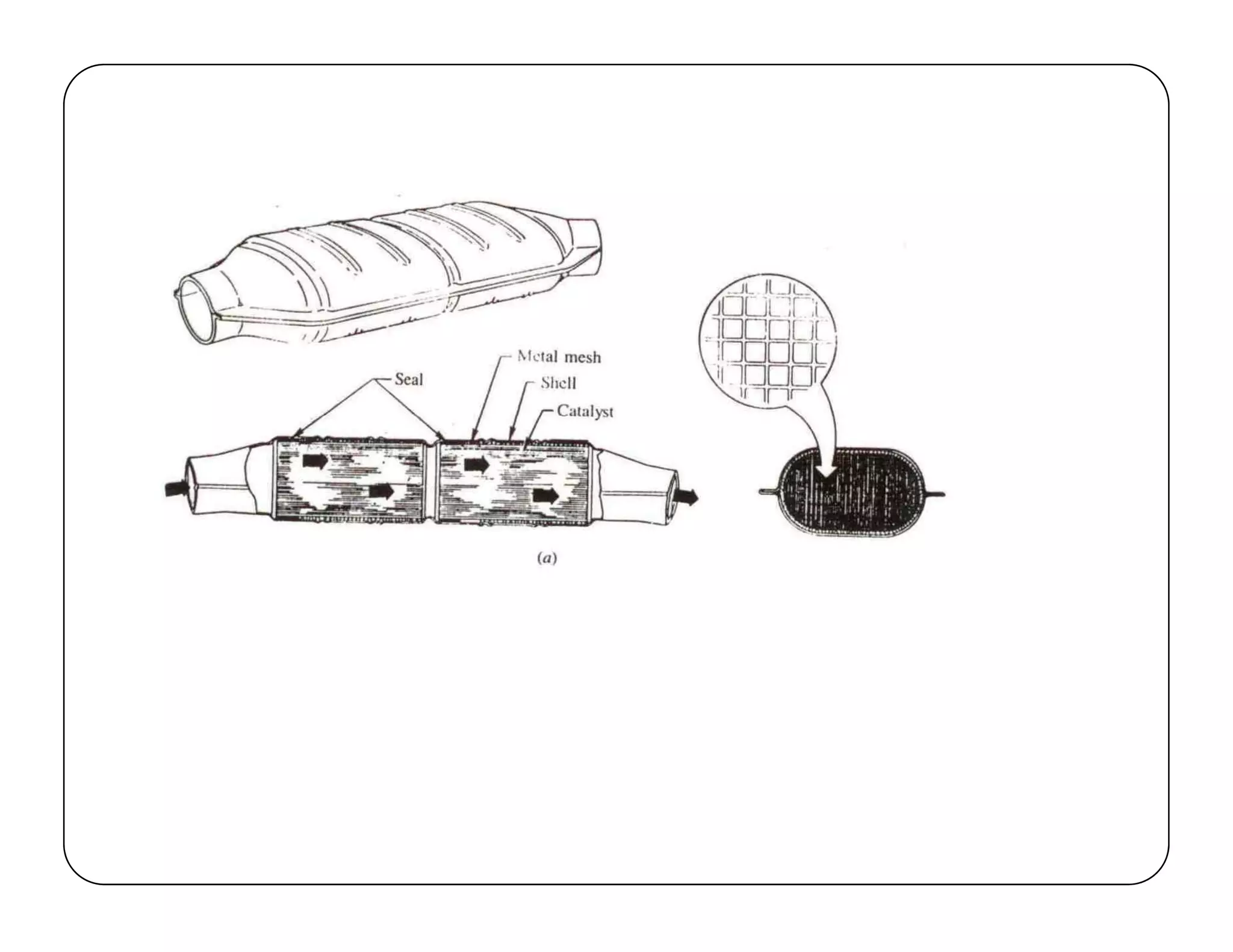

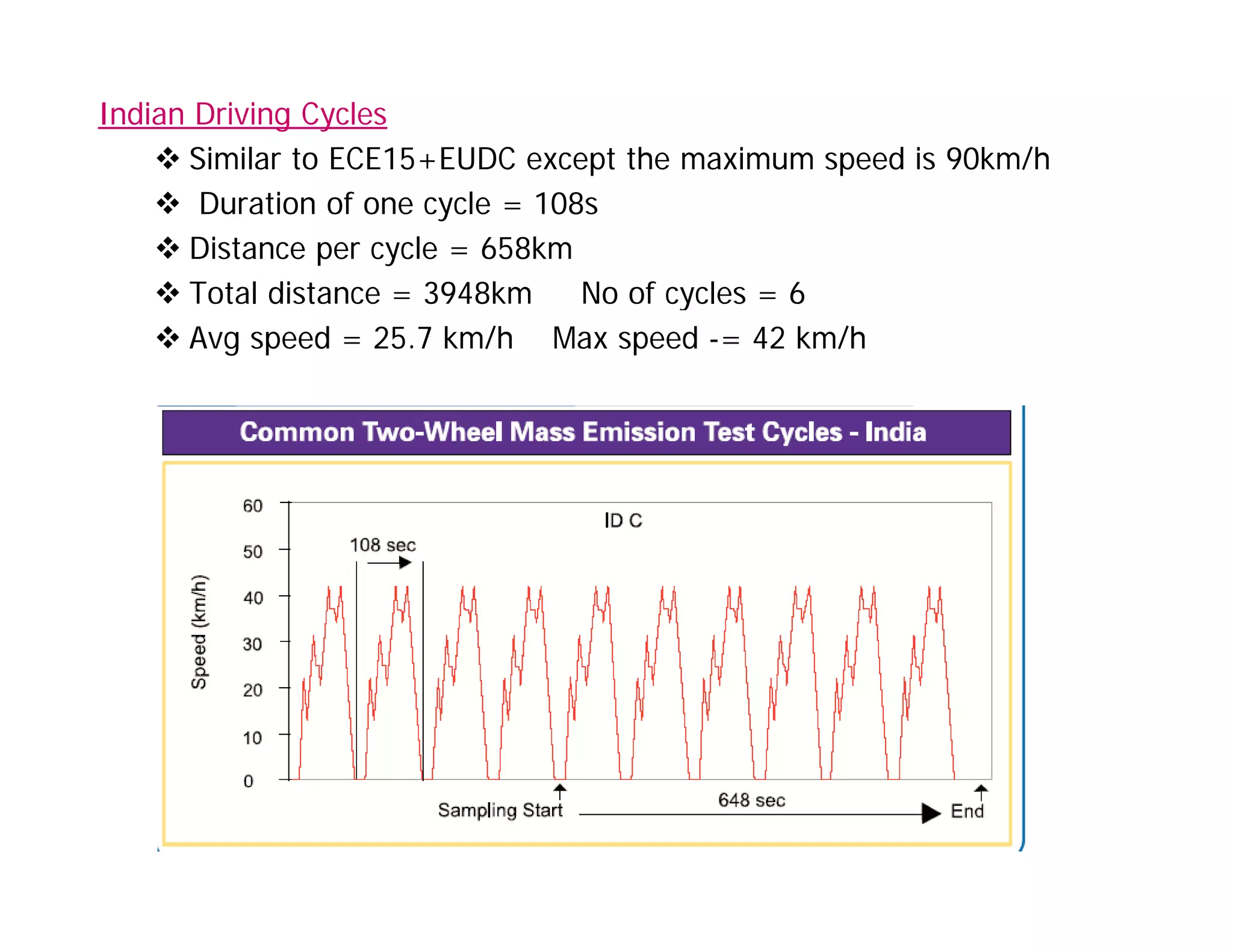

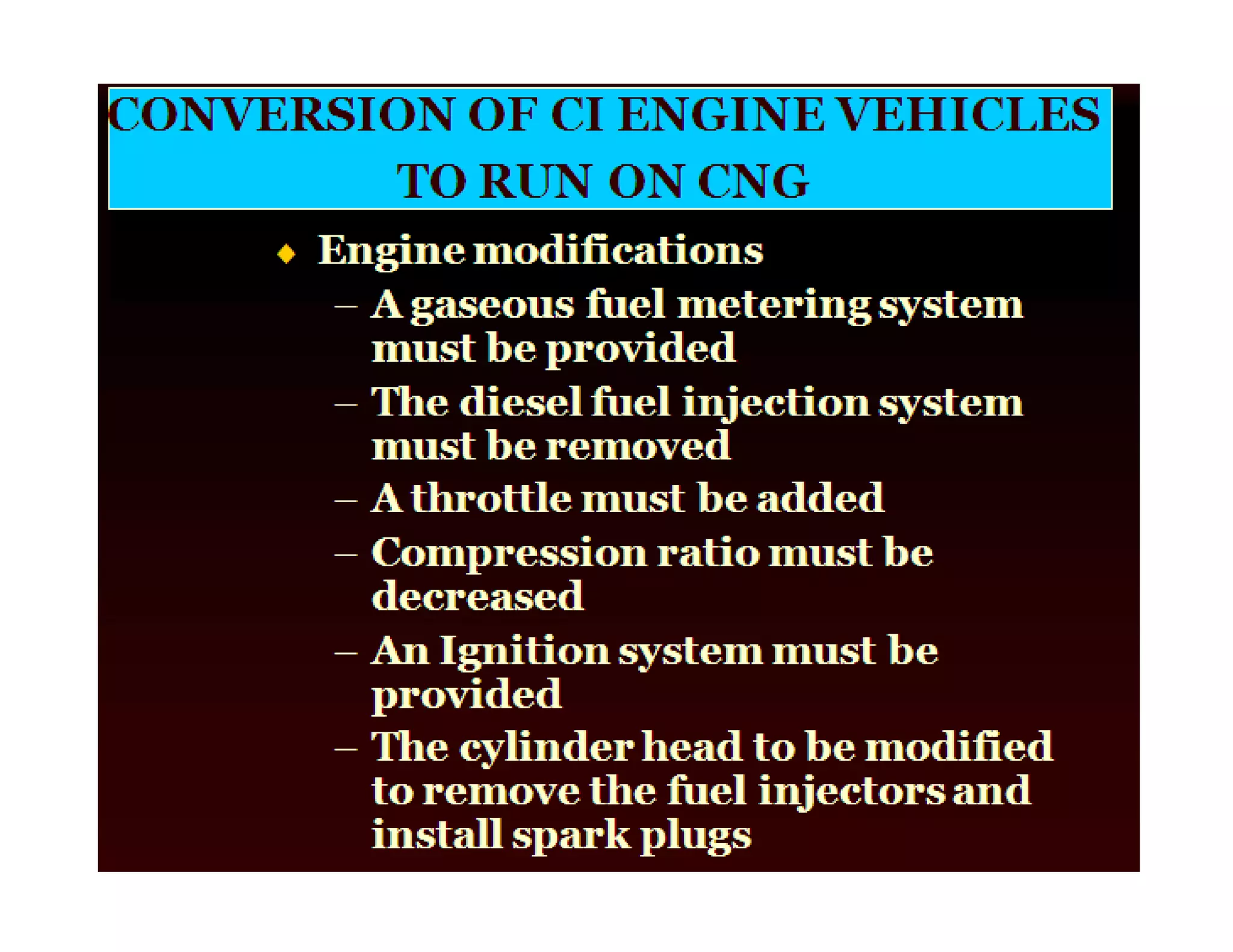

![Natural Gas Diesel Oil

• Stoichiometric air/fuel ratio [mass] 17.2 14,5

• Vapour flammability limits [Volume %] 5 - 15 -

• Flammability limits [lambda] 0,7 – 2,1 0,19 - 0,98

• Lower heating/calorific value [MJ/kg] 38 - 50 42,6

• Methane concentration [Volume %] 80 - 99 -

• Ethane concentration [Volume %] 2,7 – 4.6 -

• Nitrogen concentration [Volume %] 0,1 - 15 -

• Carbon dioxide concentration [Volume %] 1 – 5 -

• Sulphur concentration [ppm, mass] < 5 < 50

• Specific CO2 formation [g/MJ] 38 - 50 72](https://image.slidesharecdn.com/engineemissionandtheircontrol-160403142310/75/Engine-emission-and-their-control-135-2048.jpg)

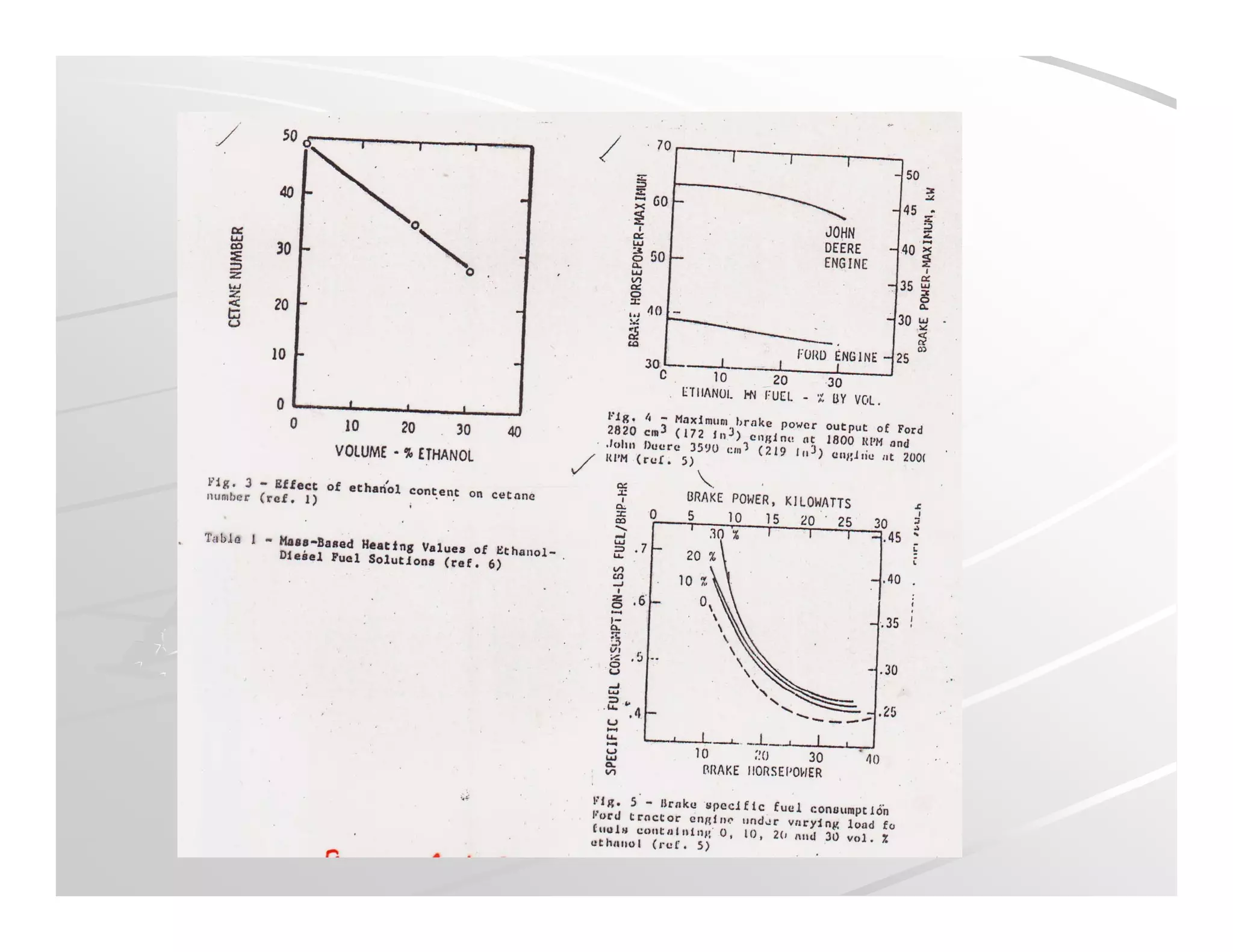

![Dual Fuel Engine Performanceg

CATERPILLAR

C-10 DFNG

ENGINE [9]](https://image.slidesharecdn.com/engineemissionandtheircontrol-160403142310/75/Engine-emission-and-their-control-149-2048.jpg)