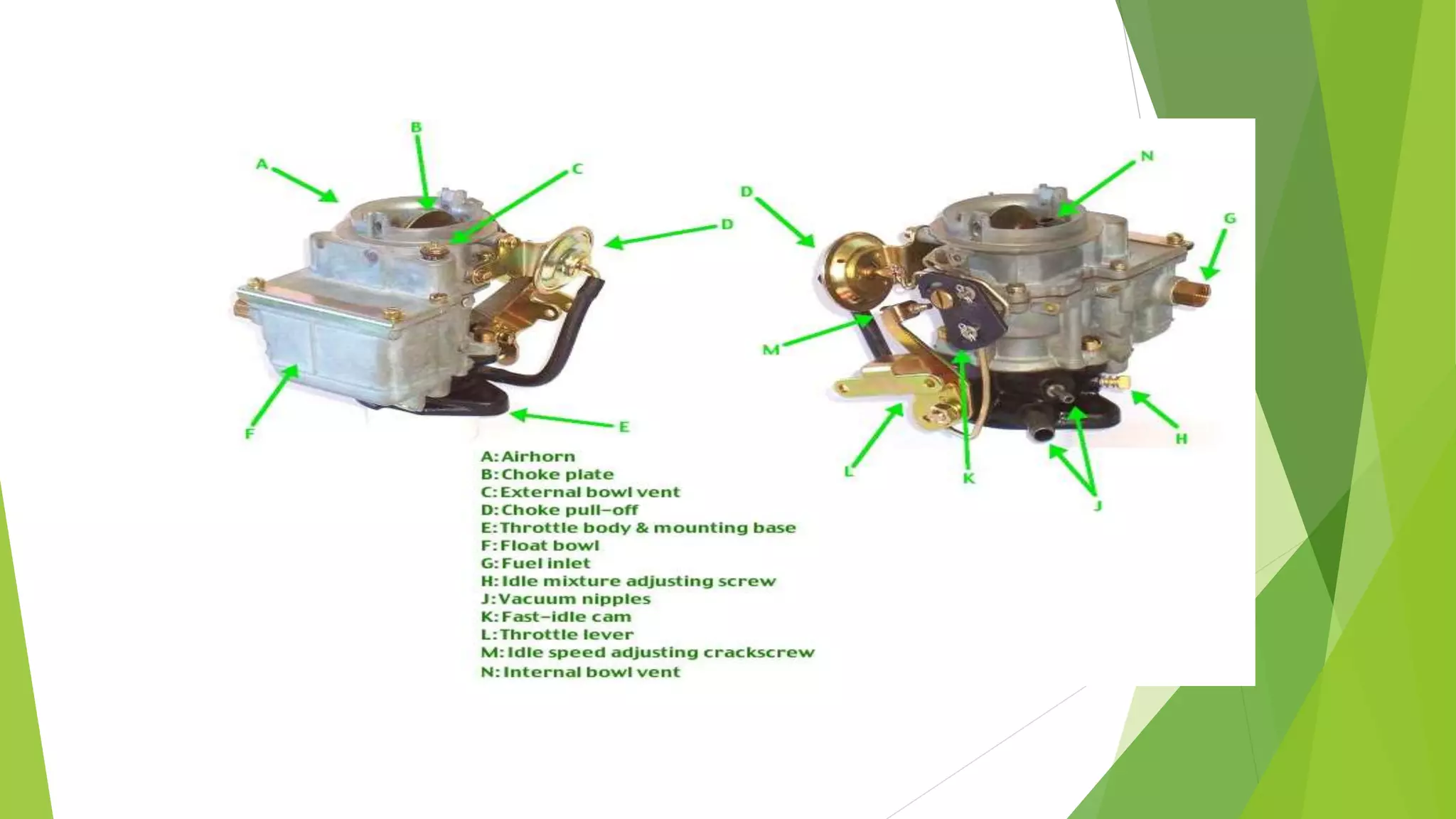

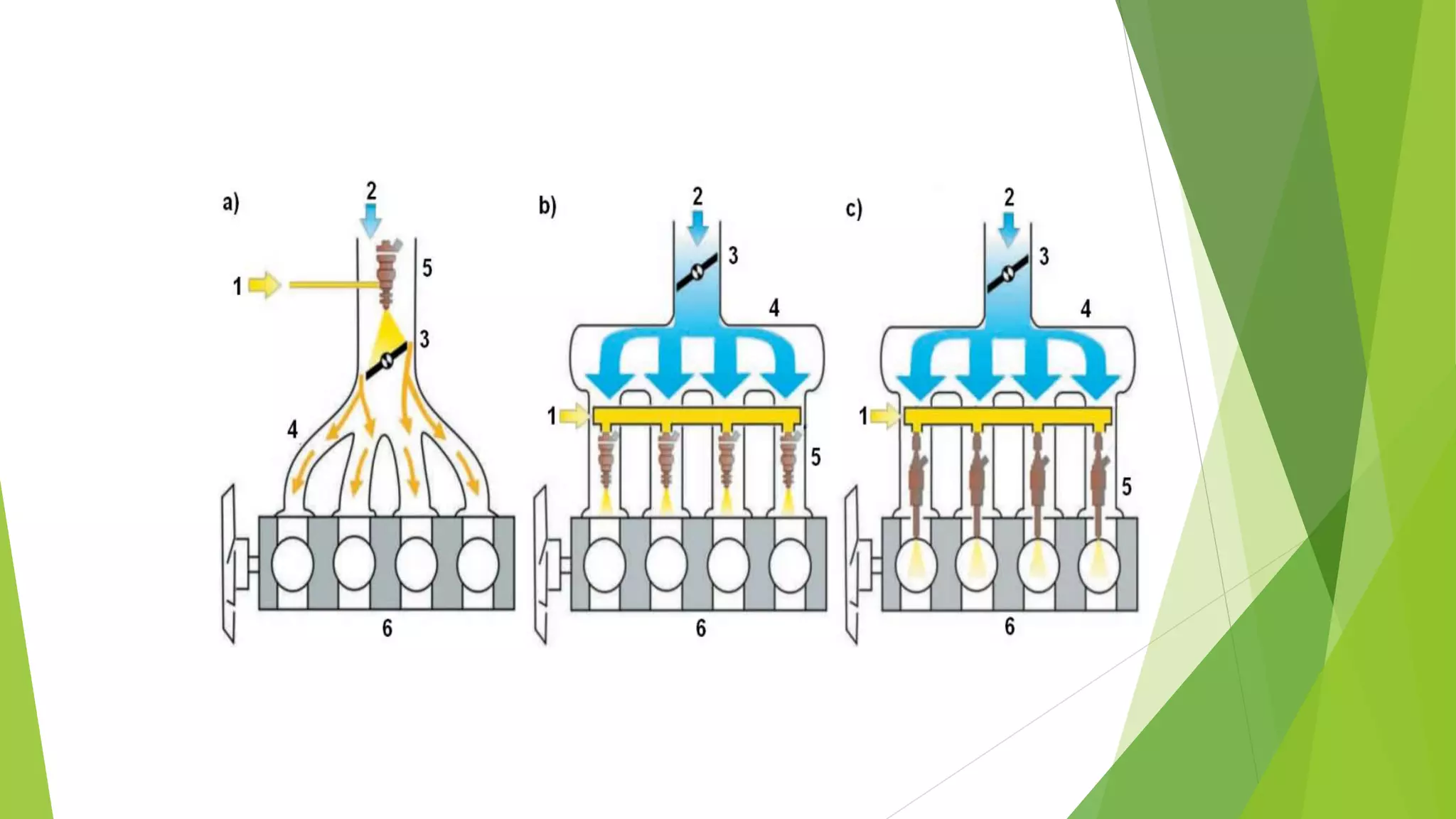

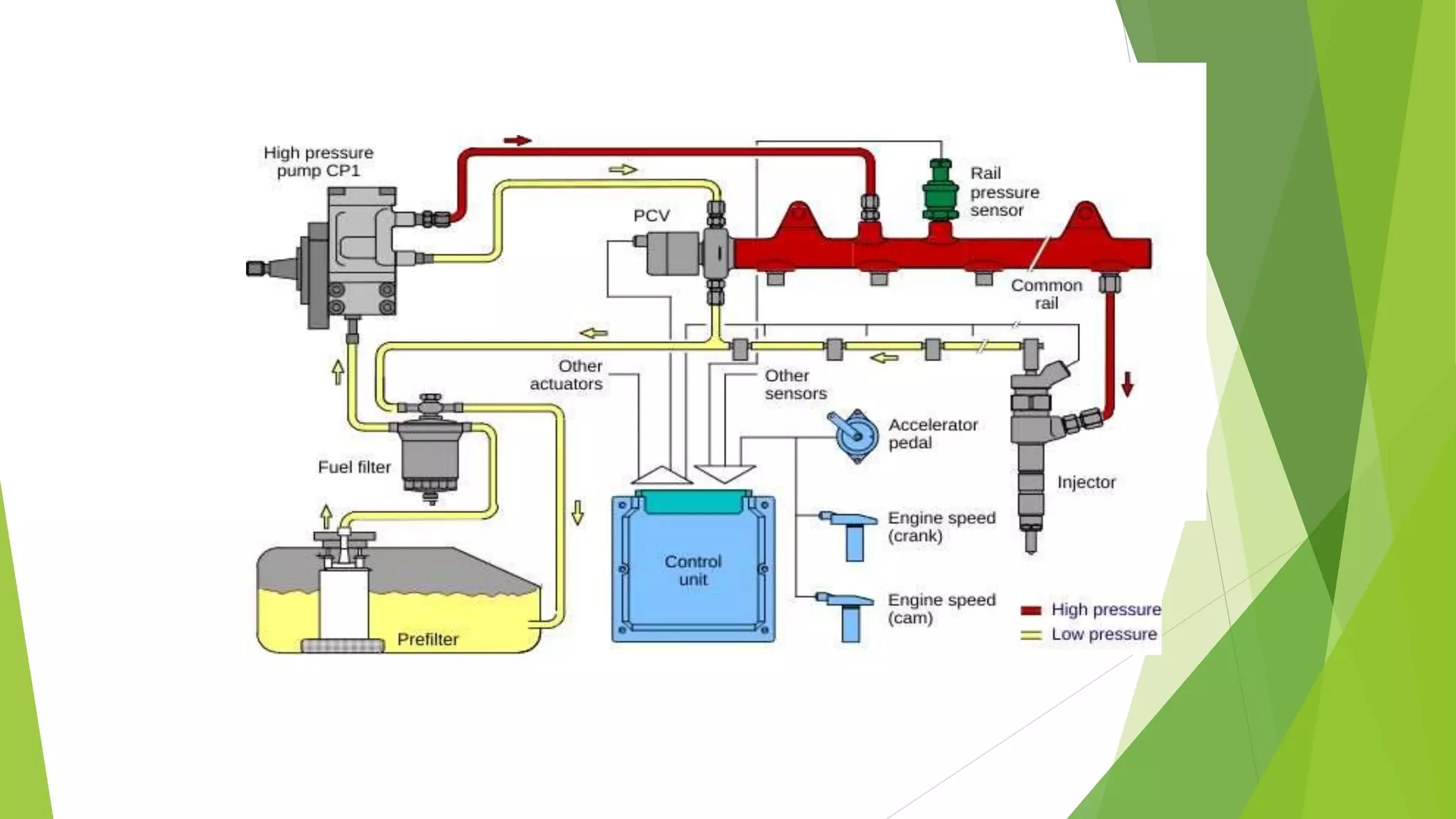

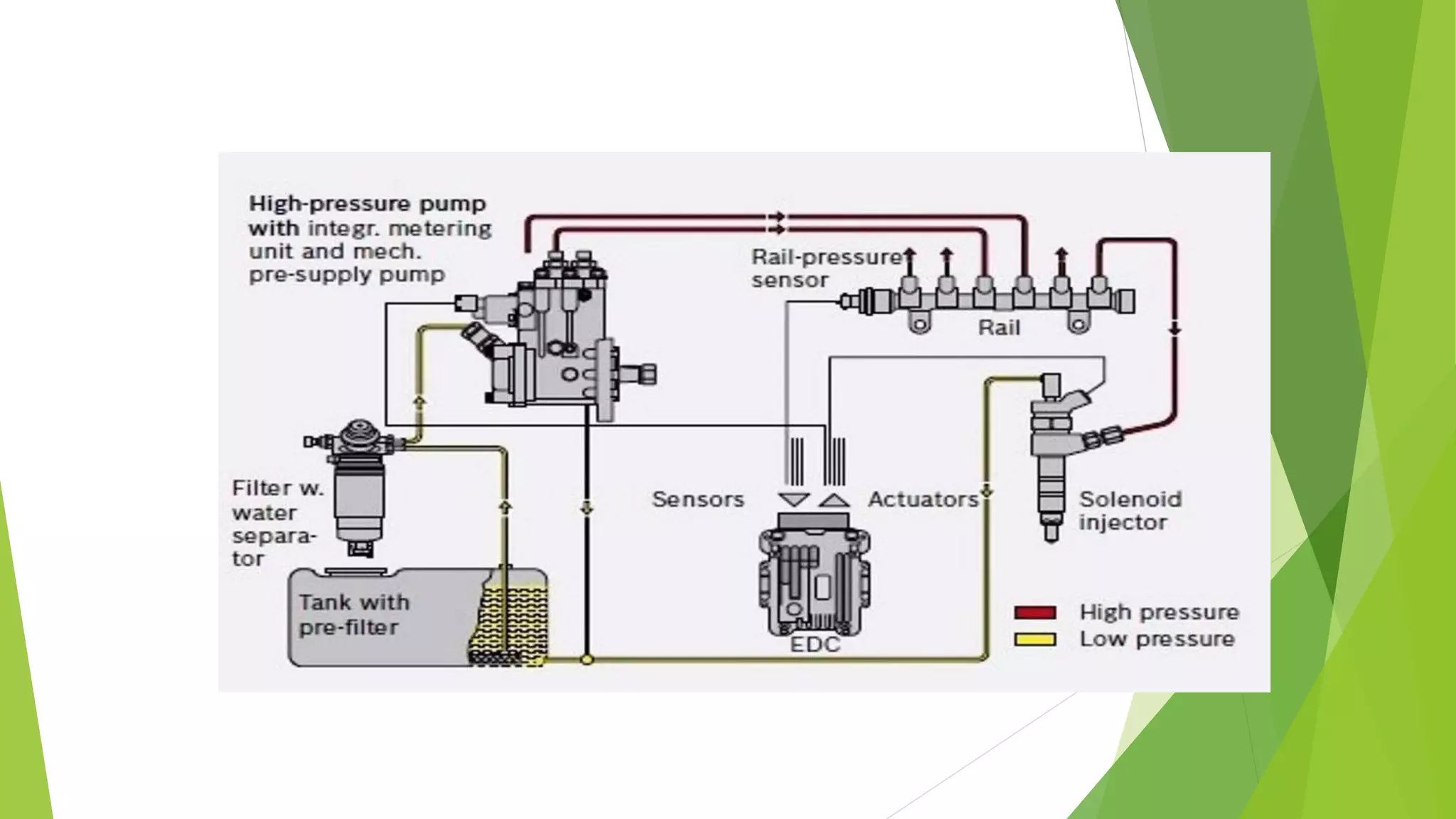

The document discusses different fuel supply systems for automobiles, including carburetion, multi-point fuel injection (MPFI), diesel fuel systems, and common rail direct injection (CRDI). It provides details on how each system works to supply the proper fuel-air mixture to engine cylinders. Carburetion mixes fuel and air before admission to the cylinder, while MPFI uses fuel injectors near each cylinder controlled by a computer. Diesel fuel systems precisely inject pressurized fuel into cylinders, and CRDI features a high-pressure rail and solenoid valves to optimize fuel injection timing and quantity.