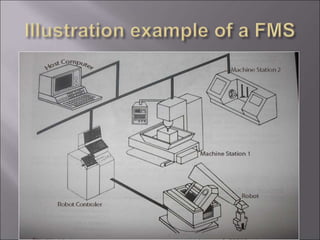

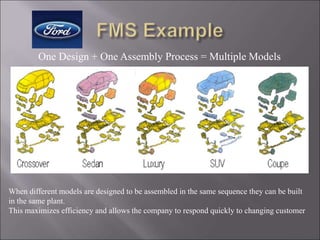

This document provides an overview of how Ford utilizes flexible manufacturing systems (FMS) to efficiently produce multiple vehicle models. Key points:

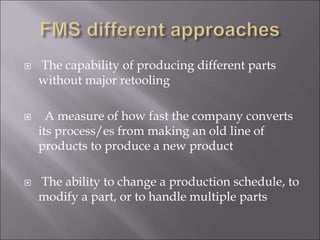

- Ford is able to build different models in the same plant by designing vehicles that can be assembled in the same sequence.

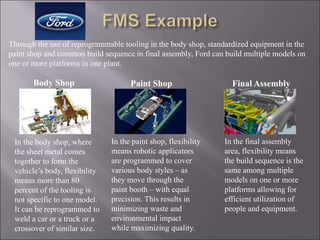

- In the body shop, over 80% of tooling is reprogrammable to weld various models. In the paint shop, robotic applicators can precisely cover different body styles. In final assembly, the build sequence is the same across models.

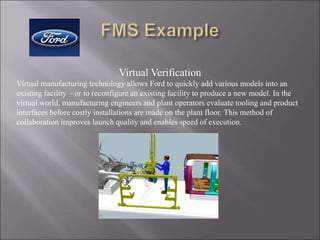

- Virtual verification technology allows Ford to quickly add new models or reconfigure plants, as manufacturing engineers can evaluate changes virtually before implementing them on the plant floor. This improves launch quality and speed of production