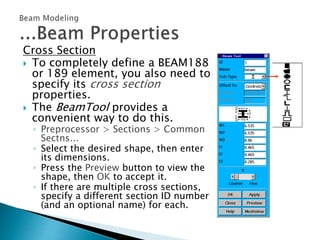

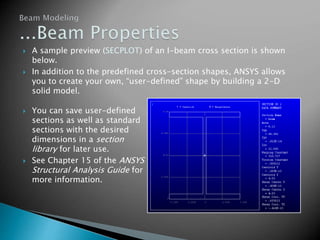

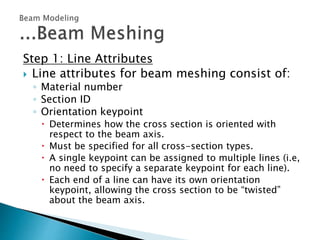

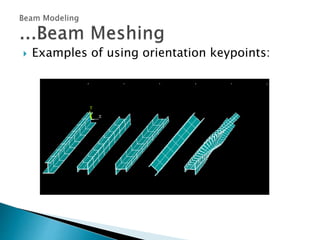

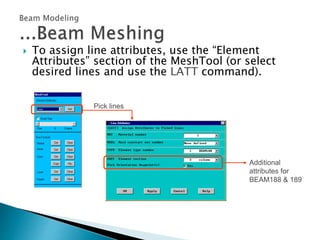

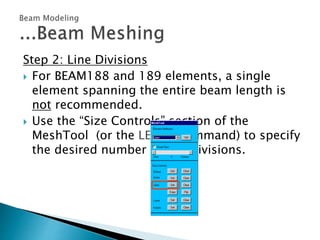

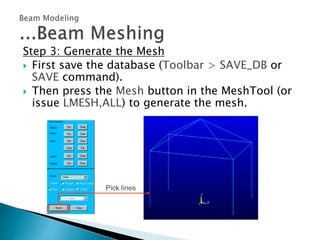

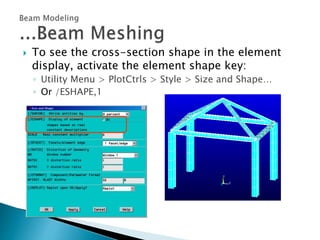

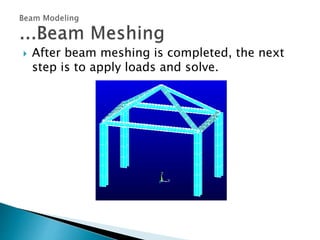

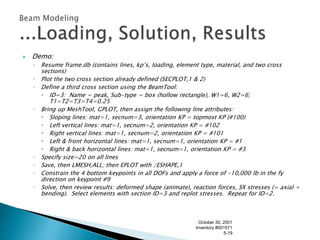

Beam elements are 1D elements used to model 3D structures in a computationally efficient manner. They are commonly used in industries like construction, bridges, transportation and more. The document outlines the process for modeling with beam elements which includes defining the geometry, beam properties like element type, cross section, material and meshing the geometry. It specifically recommends using BEAM188 and BEAM189 elements and describes how to define standard and custom cross sections. The steps for applying loads, solving, and reviewing results are also provided. An example problem is included to demonstrate modeling a frame structure with various beam elements and cross sections.