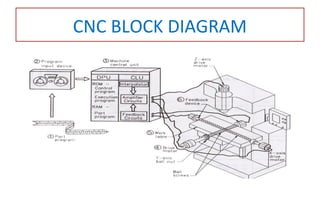

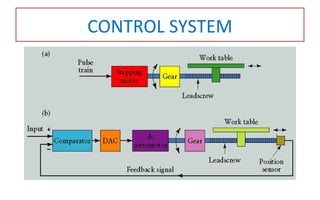

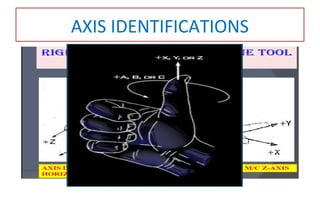

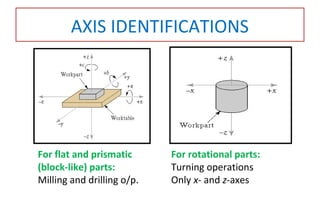

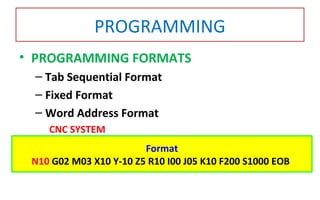

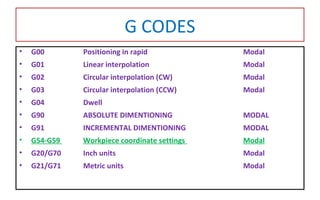

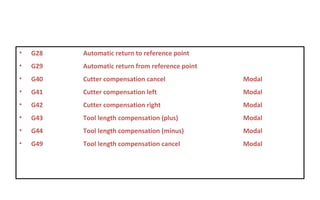

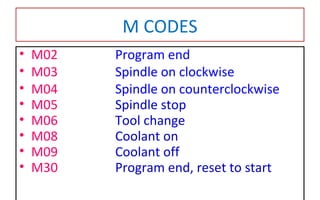

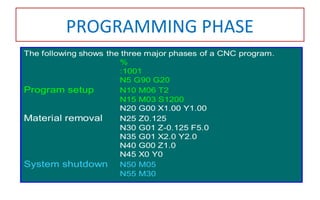

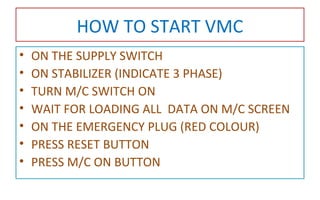

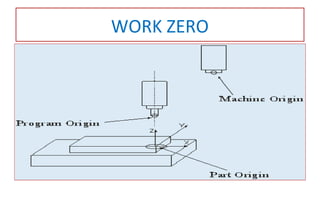

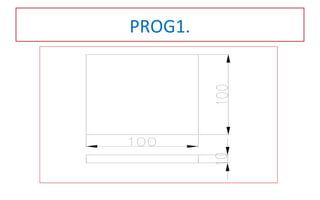

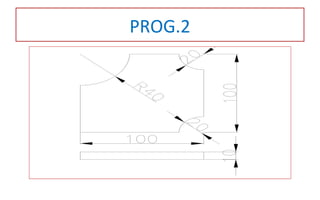

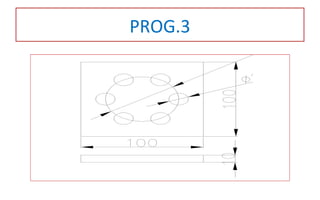

The document provides an overview of CNC machine training presented by Tarun B Patel. It includes an introduction to CNC, the constructional features of CNC machines, programming formats and codes, and a demonstration of a vertical machining center. The objective is to familiarize trainees with the VMC and how to maintain it. The presentation covers the specification, elements, operations, and programming of the VMC used in the demonstration. Sample part programs are also included to illustrate linear, circular and canned cycle operations.