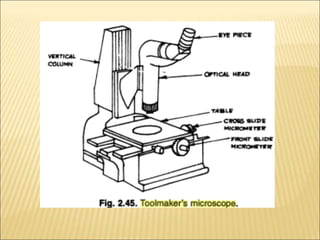

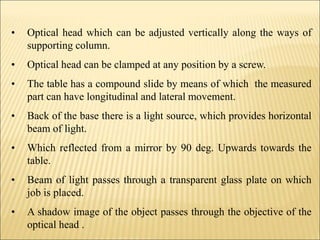

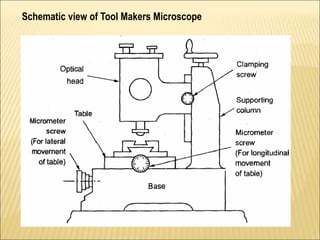

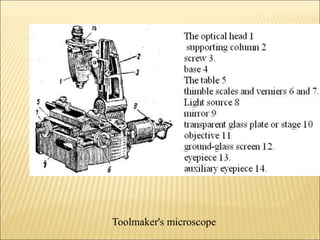

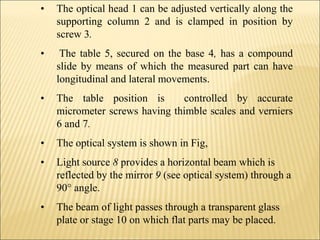

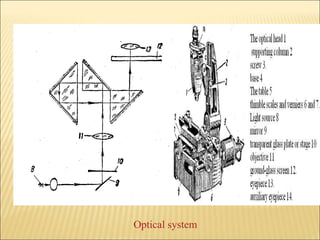

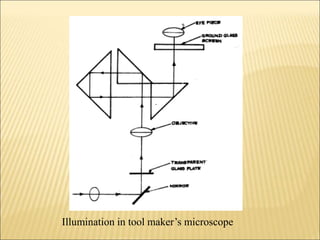

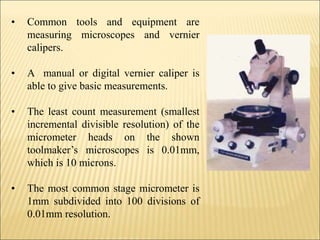

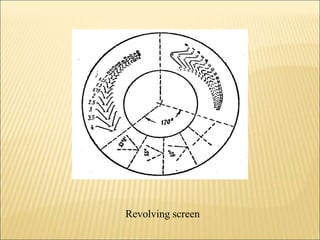

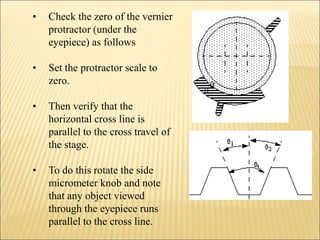

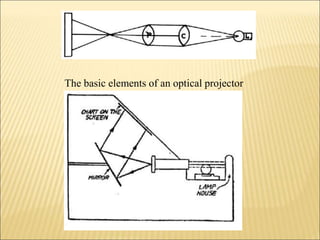

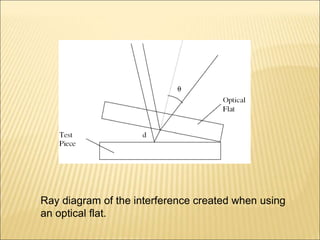

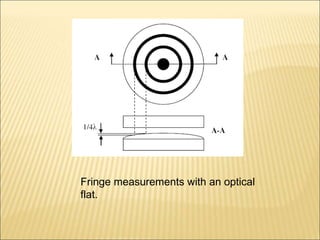

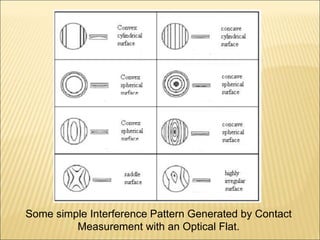

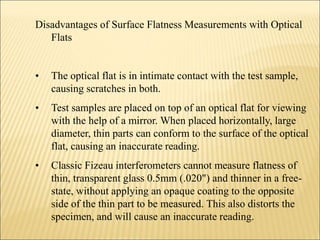

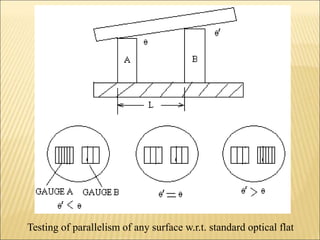

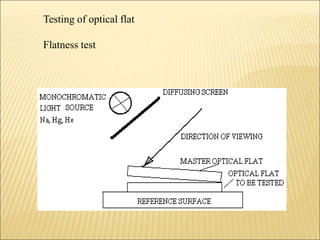

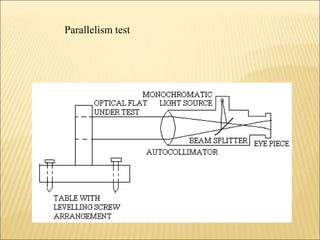

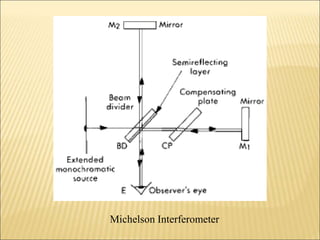

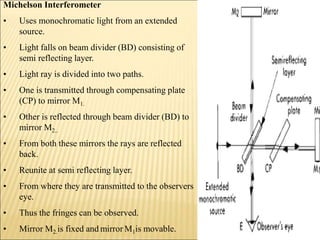

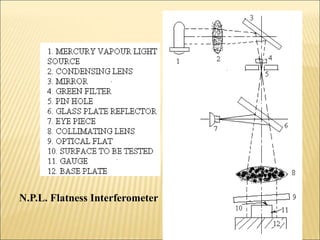

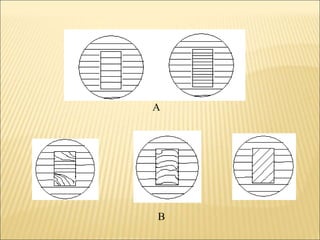

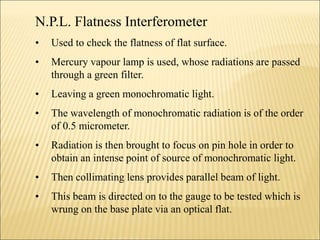

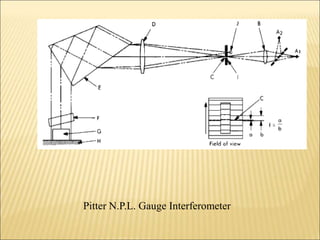

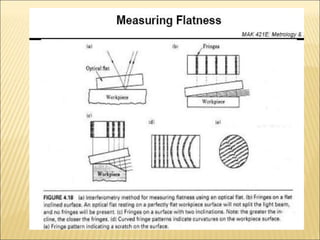

The document discusses various optical measuring instruments. It describes the engineering microscope, which provides an enlarged view of small objects to measure dimensions. It also describes the toolmakers microscope in detail. The toolmakers microscope uses optics and has a base, worktable, optical head, and ground glass screen to project and measure contours, diameters, distances between holes, and other geometric features of parts. Interference patterns created using an optical flat allow for measuring the flatness and parallelism of surfaces. Other optical measuring instruments discussed include the optical projector, interferometers like the Michelson interferometer, and sources of light used for optical measurements.