This document provides an overview of robotics and automation. It defines a robot and the key elements in a robotics system. Robots are classified based on their physical configuration, including Cartesian, cylindrical, polar and jointed arm configurations. The document discusses the applications of robotics in material handling, processing, assembly and inspection. It also outlines the advantages and disadvantages of robots and automation. Numerical control and computer numerical control machines are described as a form of programmable automation.

![ROBOTICS

“A Robot is a programmable, multi-functional

manipulator designed to move materials, parts, tools

or special devices through variable programmed

motions for performing variety of tasks”

“Robotics is the field of technology that deals with the

conception, design, construction, operation and

application of robots”

Elements of a Robotics system are:

The manipulator, End effectors, Actuators, Transmission

elements

Control system consisting of Controls [Mechanical,

Electrical, Pneumatic, Hydraulic etc.]

Sensors and Equipment interfaces

Computer systems to carry out programming

Power Source [battery/pneumatic/hydraulic etc]](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-2-320.jpg)

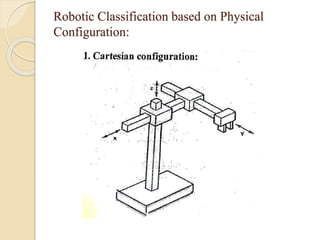

![ Cartesian Configuration [Rectilinear]:

It consists of 3 orthogonal slides namely X, Y & Z axes of the

Cartesian coordinate system

By appropriate movement, the arm of the Robot can move at any

point in the 3-dimensional rectangular spaced work space

Advantages:

o Allows for simpler control

o Possesses high degree of mechanical rigidity

o Can carry heavy loads and the lifting capability does not vary within

the work envelop

Disadvantages:

o Reduced flexibility

o Limitation in the movement of the robotic arm to a small rectangular

work space

Finds application in assembly, machining, inspection, welding etc.](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-4-320.jpg)

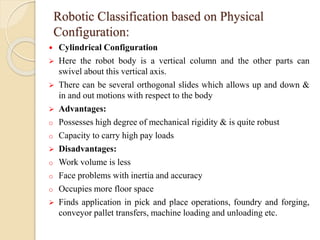

![Robotic Classification based on Physical

Configuration:

Polar Configuration [Spherical]

Here the robot body has a rotary base and a pivot that can be used to

raise and lower a telescopic arm

Within the workspace, it can move its arm in a partial sphere hence

also termed as using spherical coordinates

Advantages:

o Long reach capability in horizontal position

o Increased work envelop with increased work lifting capability

Disadvantages:

o Vertical reach is low

o Lesser rigidity with complex controls

o Problem with inertia and accuracy

Finds application in die casting, forging, injection molding, cleaning

of parts, dip coating etc](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-8-320.jpg)

![Application of Robotics:

1. Material/Part handling

2. Processing

3. Assembly

4. Inspection

1. Material/Part handling:

Pick and place

Palletizing/de-palletizing[stacking/un-stacking]

Machine loading and/or unloading

Stacking and insertion](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-11-320.jpg)

![2. Programmable automation:

Here the production equipment is designed with the capability to

change the sequence of operations to accommodate different product

configurations

The sequence of operations is controlled by a program [set of coded

instructions]

New programs can be prepared and entered into the equipment to

produce new products

• Advantages of Programmable automation:

Most suitable for batch production

Flexibility to deal with changes in the product configuration

• Disadvantages of Programmable automation:

High investment in general-purpose equipment

Low production rates compared to fixed automation

• Applications: In food processing, foundry, textile using NC

machines and PLC’s](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-17-320.jpg)

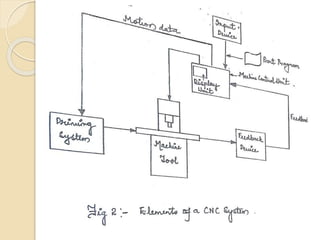

![ Disadvantages of NC machines:

High investment [NC machines costing 5-6 times the conventional

machines]

High spares and maintenance cost

Requirement of special tooling

Need for initial training of operators and up gradation of knowledge

and software

Computer numerical control machine [CNC]:

CNC is an advanced form of NC machine where the machine control

unit is a dedicated microcomputer instead of a hard wired controller

as is in a NC machine. A CNC machine consists of the following:

a) Input device

b) MCU or Machine Control Unit

c) Machine tool

d) Driving system

e) Feedback devices

f) Display unit](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-23-320.jpg)

![1. Input Device: The part program is entered into the CNC control

or MCU through the input device. The various input devices are:

i. USB flash drive

ii. Serial communication port that connects with a computer through an

interface

iii. Ethernet communication which is a more reliable and efficient

means of communication

iv. Conversational programming that allows to enter the program

manually

2. Machine control unit [MCU]: The MCU is the heart of a

CNC system which consists of the following:

a) Central processing unit [CPU] which:

i. Has a control section to fetch the data from memory and generates

signals to activate all MCU components

ii. Arithmetic logic unit [ALU] that performs integer and logical

operations

iii. Immediate access memory that holds the data and programs

temporarily as required at the instant by the control section](https://image.slidesharecdn.com/roboticsautomation-180421032859/85/Robotics-and-Automation-25-320.jpg)